Preparation method of silicon-coated lithium ion battery anode material

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of reduced material capacity, poor material conductivity, high processing temperature, etc., and achieve uniform particle distribution, low processing temperature, and uniform particles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

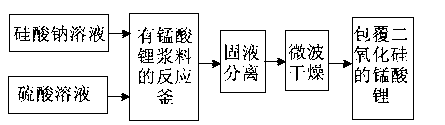

Method used

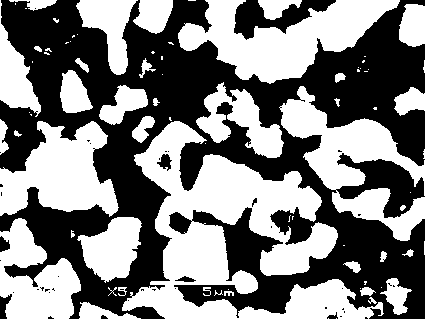

Image

Examples

Embodiment 1

[0025] ①Prepare 800kg of lithium manganate matrix, put it into a reaction kettle with high-speed stirring and jacket system, and prepare a slurry with pure water with a solid content of 160g / L.

[0026] ②According to the amount of lithium manganate, prepare 3% SiO containing its molar amount 2 A solution of sodium silicate, SiO 2 The mass concentration is 5.3%, that is, weigh Na 2 O.·3.1SiO 2 Powder 10.6kg, prepared as 150 liters of solution.

[0027] ③ Dilute sulfuric acid with pure water to prepare a solution with a mass concentration of 3%.

[0028] Prepare the lithium manganate slurry, the pH value is controlled at 9.5, the temperature is 70±2°C, the stirring speed is 120r / min, and the ②solution and ③solution metering pumps are used to feed simultaneously, ②The feeding speed of the solution sodium silicate 1.0L / min, the pH value of the system is controlled at 9.4~9.6, after the sodium silicate reaction is completed, the material is discharged, the slurry is separated f...

Embodiment 2

[0030] ① Prepare 800kg of lithium manganate matrix, put it into a reaction kettle with high-speed stirring and jacket system, and prepare a slurry with pure water, with a solid content of 180g / L.

[0031] ②According to the amount of lithium manganate, prepare 4% SiO containing its molar amount 2 A solution of sodium silicate, SiO 2 The mass concentration is 5.3%, that is, weigh Na 2 O.·3.1SiO 2 Powder 14.13kg, prepared as 200 liters of solution.

[0032] ③ Dilute sulfuric acid with pure water to prepare a solution with a mass concentration of 3%.

[0033] Prepare the lithium manganate slurry, the pH value is controlled at 9.6, the temperature is 75±2°C, the stirring speed is 120r / min, and the ②solution and ③solution metering pumps are used to feed simultaneously, ②The feeding speed of the solution sodium silicate 1.5L / min, the pH value of the system is controlled at 9.5~9.7, the sodium silicate is discharged after the reaction is completed, the solid-liquid separation is c...

Embodiment 3

[0035] ①Prepare 800kg of lithium manganate matrix, put it into a reaction kettle with high-speed stirring and jacket system, and prepare a slurry with pure water with a solid content of 180g / L.

[0036] ②According to the amount of lithium manganate, prepare 5% SiO containing its molar amount 2 A solution of sodium silicate, SiO 2 The mass concentration is 6.6%, that is, weigh Na 2 O.·3.1SiO 2 Powder 17.7kg, prepared as 200 liters of solution.

[0037] ③ Dilute sulfuric acid with pure water to prepare a solution with a mass concentration of 3%.

[0038] Prepare the lithium manganate slurry, the pH value is controlled at 9.5, the temperature is 70±1°C, the stirring speed is 150r / min, and the ②solution and ③solution metering pumps are used to feed simultaneously, ②The feeding speed of the solution sodium silicate 1.5L / min, the pH value of the system is controlled at 9.4~9.6, after the sodium silicate reaction is completed, the material is discharged, the slurry is separated f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com