Preparation method of instant winter jujube powder and product thereof

A technology for dissolving winter jujube powder and winter jujube is applied in the field of preparation of instant winter jujube powder, which can solve the problems of difficulty in obtaining economic benefits for enterprises, large environmental pollution of emissions, destruction of nutrients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

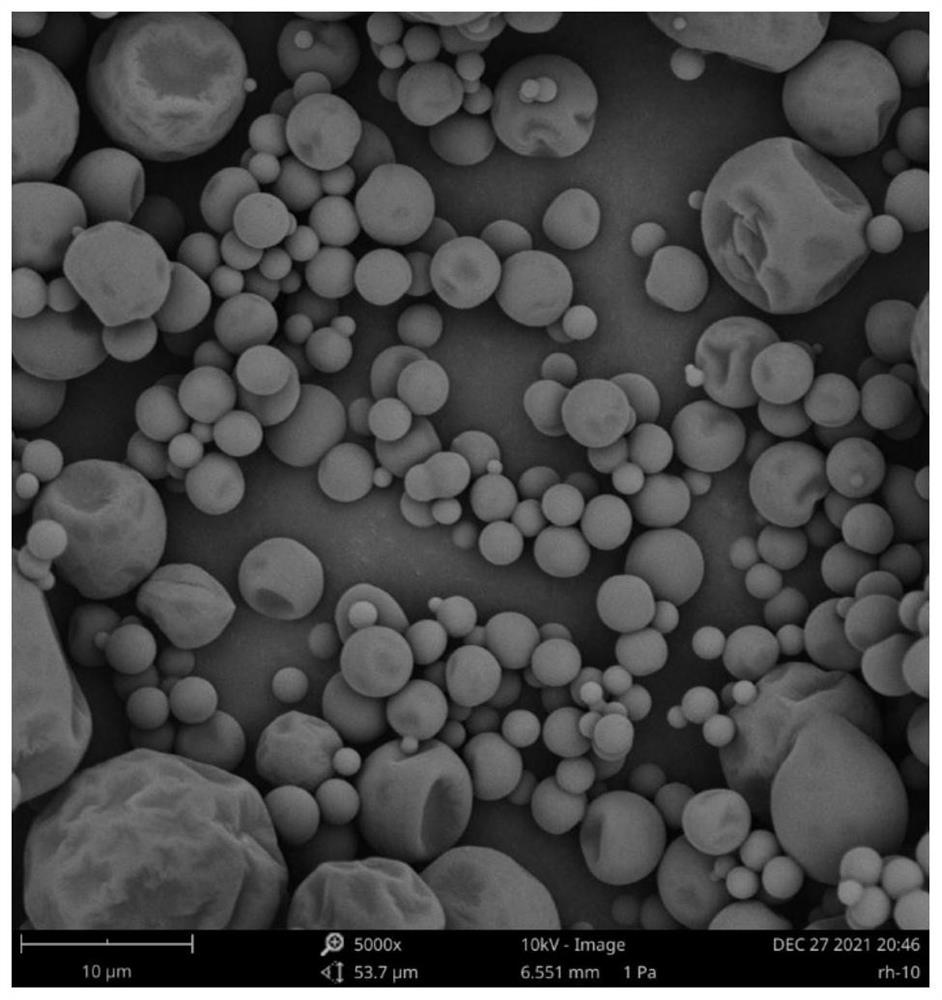

Image

Examples

Embodiment 1

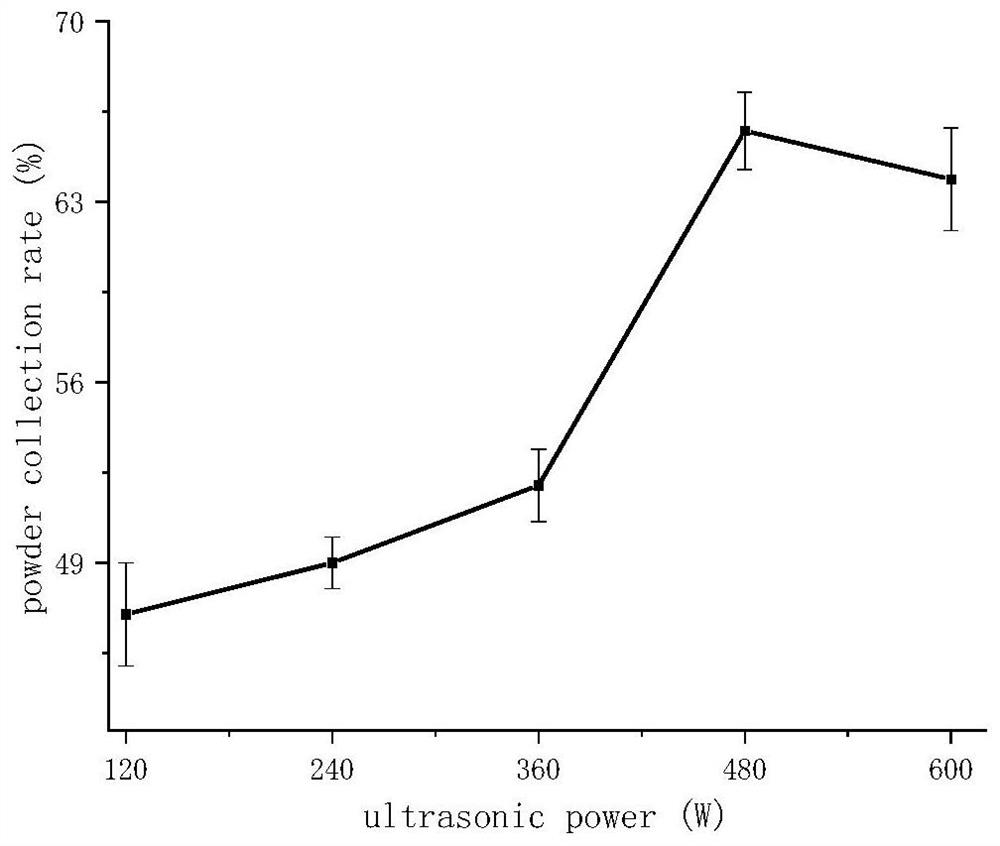

[0027] Embodiment 1, the preparation of instant winter jujube powder (ultrasonic treatment+pectinase enzymolysis+cellulase enzymolysis)

[0028] Cut the cleaned winter jujube into 8 pieces after removing the core, add pure water equivalent to three times the mass of winter jujube, ultrasonically treat at 45°C and 480W power for 30 minutes, then add pectinase for the first enzymolysis, add enzyme The amount is 0.25mL / g, the enzymatic hydrolysis temperature is 40°C, the enzymatic hydrolysis pH is 4, and the enzymatic hydrolysis time is 2h. After the first enzymatic hydrolysis is completed, microwave 700W to inactivate the enzyme for 1min, and then add cellulase for the second enzymatic The amount of enzyme added is 0.35mL / g, the enzymatic hydrolysis temperature is 55°C, the enzymatic hydrolysis pH is 7, and the enzymatic hydrolysis time is 4h. After the second enzymatic hydrolysis is completed, microwave 700W to inactivate the enzyme for 1min, and beat with a wall breaker for 5mi...

Embodiment 1

[0029] Comparative example 1, the preparation of instant winter jujube powder (not ultrasonic treatment, not enzymolysis)

[0030] Cut the cleaned winter jujube into 8 pieces after removing the core, add pure water equivalent to 3 times the mass of winter jujube, beat with a wall breaker for 5 minutes, filter through a 150-mesh filter, and rotate the filtrate until the soluble solid content is 14%. For jujube pulp, add 5% maltodextrin, 5% resistant dextrin and 1% whey protein isolate equivalent to the quality of jujube pulp. After mixing evenly, the material liquid is subjected to ultra-high pressure micro-jet under the condition of a pressure of 90MPa homogeneous, and then spray-dried under the conditions of an air inlet temperature of 140° C., a feed rate of 0.45 mL / h, and a feed concentration of 14%, to obtain instant winter jujube powder.

Embodiment 2

[0031] Comparative example 2, the preparation of instant jujube powder (ultrasonic treatment)

[0032] Cut the cleaned winter jujube into 8 petals after removing the core, add pure water equivalent to three times the mass of winter jujube, ultrasonically treat at 45°C and 480W power for 30 minutes, beat with a wall breaker for 5 minutes, and filter through a 150-mesh filter. The filtrate is rotary evaporated until the soluble solids content is 14% to obtain jujube pulp, add maltodextrin equivalent to 5% of the quality of jujube pulp, 5% resistant dextrin and 1% whey protein isolate, after mixing evenly, the material The liquid is subjected to ultra-high pressure micro-jet homogenization under the condition of a pressure of 90MPa, and then spray-dried under the conditions of an inlet air temperature of 140°C, a feed rate of 0.45mL / h, and a feed concentration of 14%, to obtain instant winter jujube. pink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com