Preparation method of shape-controlled nano ceramic spherical particles for plasma etching resistant thermal spraying

A technology of nano-ceramics and ion corrosion, which is applied in the direction of coating, fusion spraying, metal material coating process, etc., can solve the problems of poor spherical shape of particles, large particle size of yttrium oxide, and few high-temperature furnaces, etc. Uniform particle size, low processing temperature, and improved density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

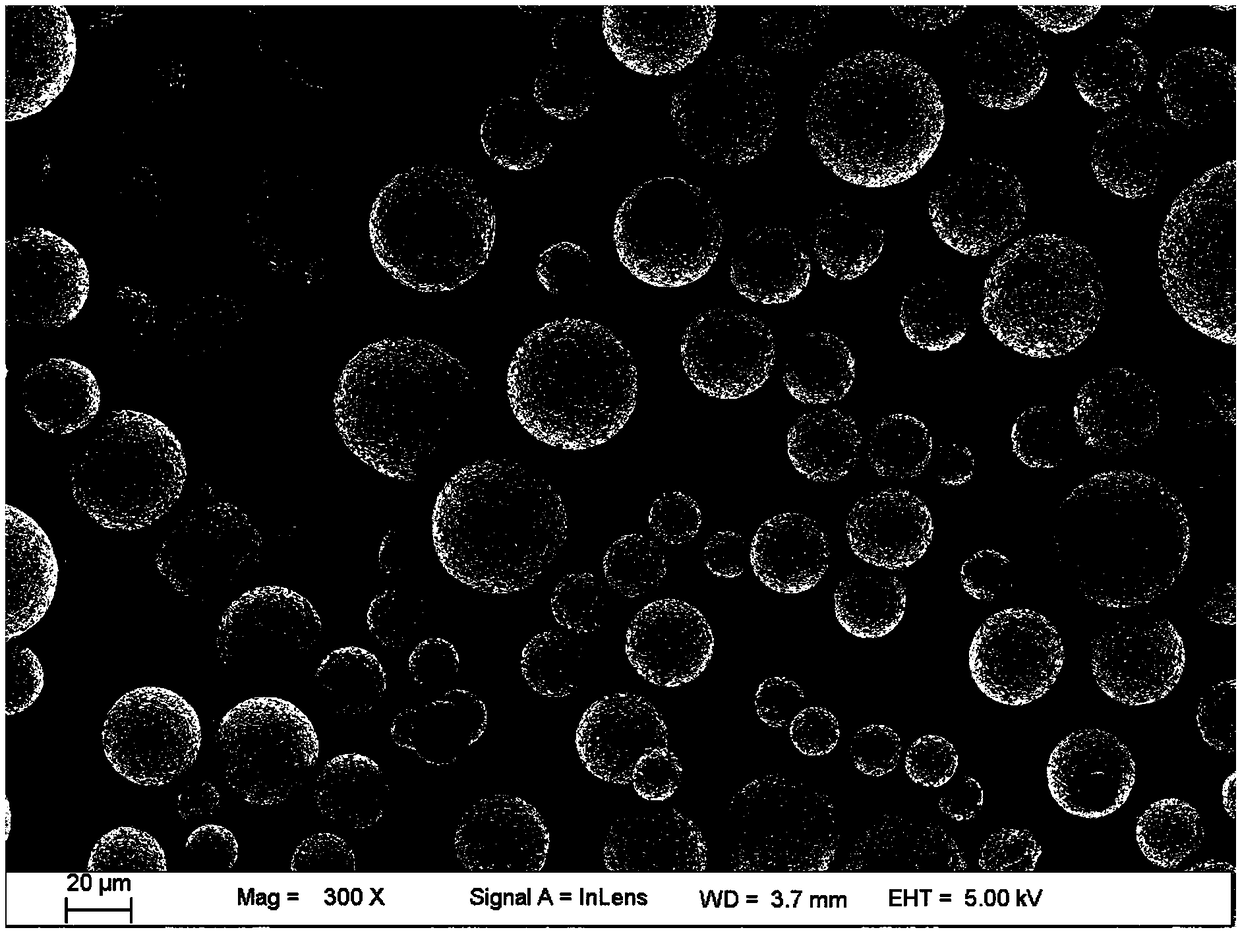

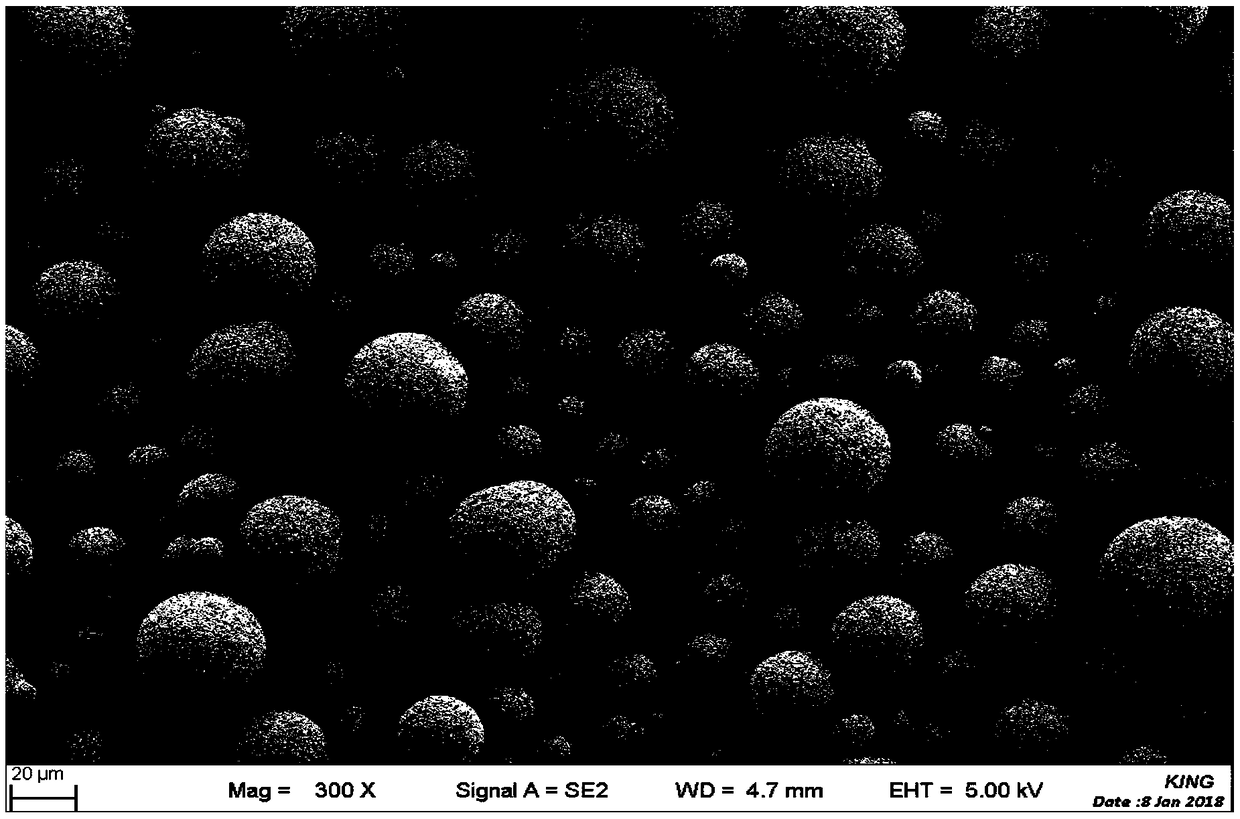

[0032] Preparation of morphology-controllable nano-ceramic spherical particles for plasma corrosion-resistant thermal spraying:

[0033] (1) Preparation of yttrium-containing inorganic salt solution: take 53.1L of 1.5mol / L yttrium chloride solution (equivalent to 9kg of yttrium oxide) and put it into a reaction tank, add 212.7L deionized water, and prepare 0.3mol / L chlorination solution Yttrium solution;

[0034] (2) Deploying surfactant: Take 180g of polyethylene glycol 2000 and add 360g of pure water to fully stir until uniform;

[0035] (3) The prepared surfactant is added in the yttrium chloride solution, fully mixed to uniform;

[0036] (4) Take 9kg of sodium carbonate crystals and 5.4kg of sodium hydroxide crystals respectively, add 733.3L of deionized water to fully dissolve, and prepare a 0.3mol / L crystal solution, and add the crystal solution to the chlorinated solution at a flow rate of 3.8L / min in yttrium solution;

[0037] (5) Stop after adding the pH value of t...

Embodiment 2

[0044] Preparation of morphology-controllable nano-ceramic spherical particles for plasma corrosion-resistant thermal spraying:

[0045] (1) Preparation of yttrium-containing inorganic salt solution: get 53.1L of 1.5mol / L yttrium chloride solution and put it into a reaction tank, add deionized water, and prepare 0.4mol / L yttrium chloride solution;

[0046] (2) Deploying surfactant: take 270g sodium lauryl sulfate and add 540g pure water and fully stir until uniform;

[0047] (3) The prepared surfactant is added in the yttrium chloride solution, fully mixed to uniform;

[0048] (4) Get 9kg of sodium carbonate crystals and 5.4kg of sodium hydroxide crystals respectively, add 733.3L of deionized water to fully dissolve, and then prepare a crystal solution of 0.3mol / L, and add the crystal solution to yttrium chloride at a flow rate of 4L / min in solution;

[0049] (5) Stop after adding the pH value of the yttrium chloride solution to 7.5, after fully stirring, aging for 3 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com