Low temperature NH3-SCR denitration catalyst for flue gas with low water vapor content, and preparation method thereof

A technology of NH3-SCR and catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It can solve the problems of unexamined catalyst activity and achieve high and low temperature activity , The effect of simple preparation process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Weigh 7.44g of niobium oxalate and dissolve in 20ml of deionized water at 50°C. After the niobium oxalate is completely dissolved, add 21.05g of cerium nitrate and 7.92g of manganese acetate to the niobium oxalate solution to form a mixed solution, and add 12.91g of TiO 2 Prepare the mixture, keep the mixture at 50°C and stir for 1 hour to make the mixture fully homogeneous, and let stand for 1 hour. Dry at 120°C for 12 hours and bake at 550°C for 6h. The roasted product is cooled, pulverized, sieved, and the powder smaller than 80 mesh is taken for later use. Weigh 7.00g of powder less than 80 mesh and mix with 3.00g of pseudo-boehmite powder evenly, add 2.0ml of 10wt% nitric acid solution to the mixed powder and mix evenly to form a dough, put it into a syringe and extrude into strips, Drying at 550°C for 6 hours. Cool after roasting, crush and sieve to take the 20-40 mesh part as the catalyst.

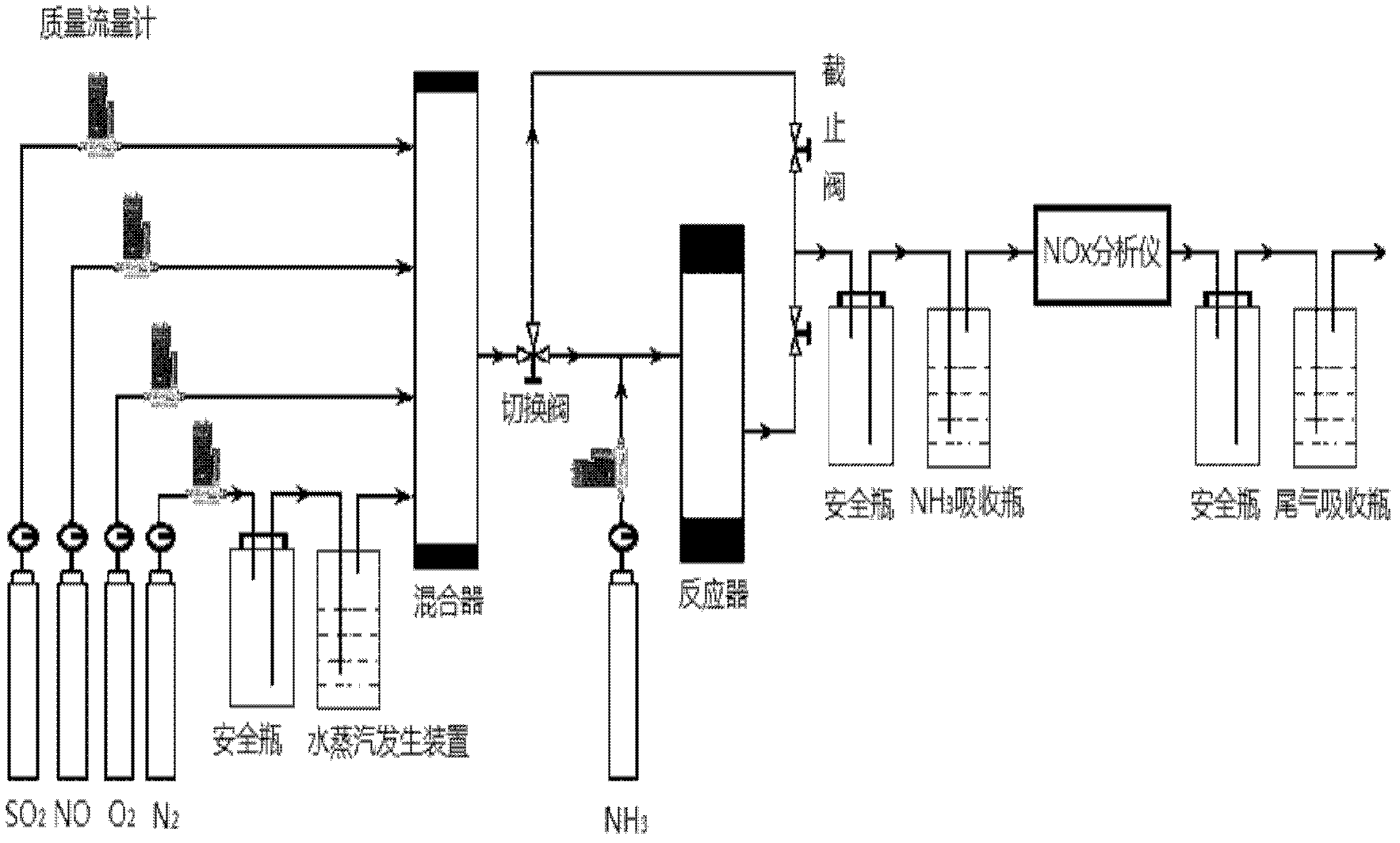

[0046] The detection method of the denitrification rate of the prepa...

Embodiment 2

[0052] Weigh 1.86g of niobium oxalate and dissolve in 20ml of deionized water at 50°C. After the niobium oxalate is completely dissolved, add 21.05g of cerium nitrate and 7.92g of manganese acetate into the niobium oxalate solution to form a mixed solution, and add 12.91g of TiO 2 Prepare the mixture, keep the mixture at 50°C and stir for 1 hour to make the mixture fully homogeneous, and let stand for 1 hour. Dry at 120°C for 12 hours and bake at 550°C for 6h. The roasted product is cooled, pulverized, sieved, and the powder smaller than 80 mesh is taken for later use. Weigh 7.00g of powder less than 80 mesh and mix with 3.00g of pseudo-boehmite powder evenly, add 2.0ml of 10wt% nitric acid solution to the mixed powder and mix evenly to form a dough, put it into a syringe and extrude into strips, Drying at 550°C for 6 hours. Cool after roasting, crush and sieve to take the 20-40 mesh part as the catalyst.

[0053] The detection method of the denitration rate of the prepare...

Embodiment 3

[0056] Weigh 21.05g of cerium nitrate and 7.92g of manganese acetate dissolved in 20ml of deionized water at 50°C to form a mixed solution, and add 12.91g of TiO to the mixed solution 2 Prepare the mixture, keep the mixture at 50°C and stir for 1 hour to make the mixture fully homogeneous, and let stand for 1 hour. Dry at 120°C for 12 hours and bake at 550°C for 6h. The roasted product is cooled, pulverized, sieved, and the powder smaller than 80 mesh is taken for later use. Weigh 7.00g of powder less than 80 mesh and mix with 3.00g of pseudo-boehmite powder evenly, add 2.0ml of 10wt% nitric acid solution to the mixed powder and mix evenly to form a dough, put it into a syringe and extrude into strips. Drying at 550°C for 6 hours. Cool after roasting, crush and sieve to take the 20-40 mesh part as the catalyst.

[0057] The detection method of the denitration rate of the prepared catalyst is the same as that in Example 1.

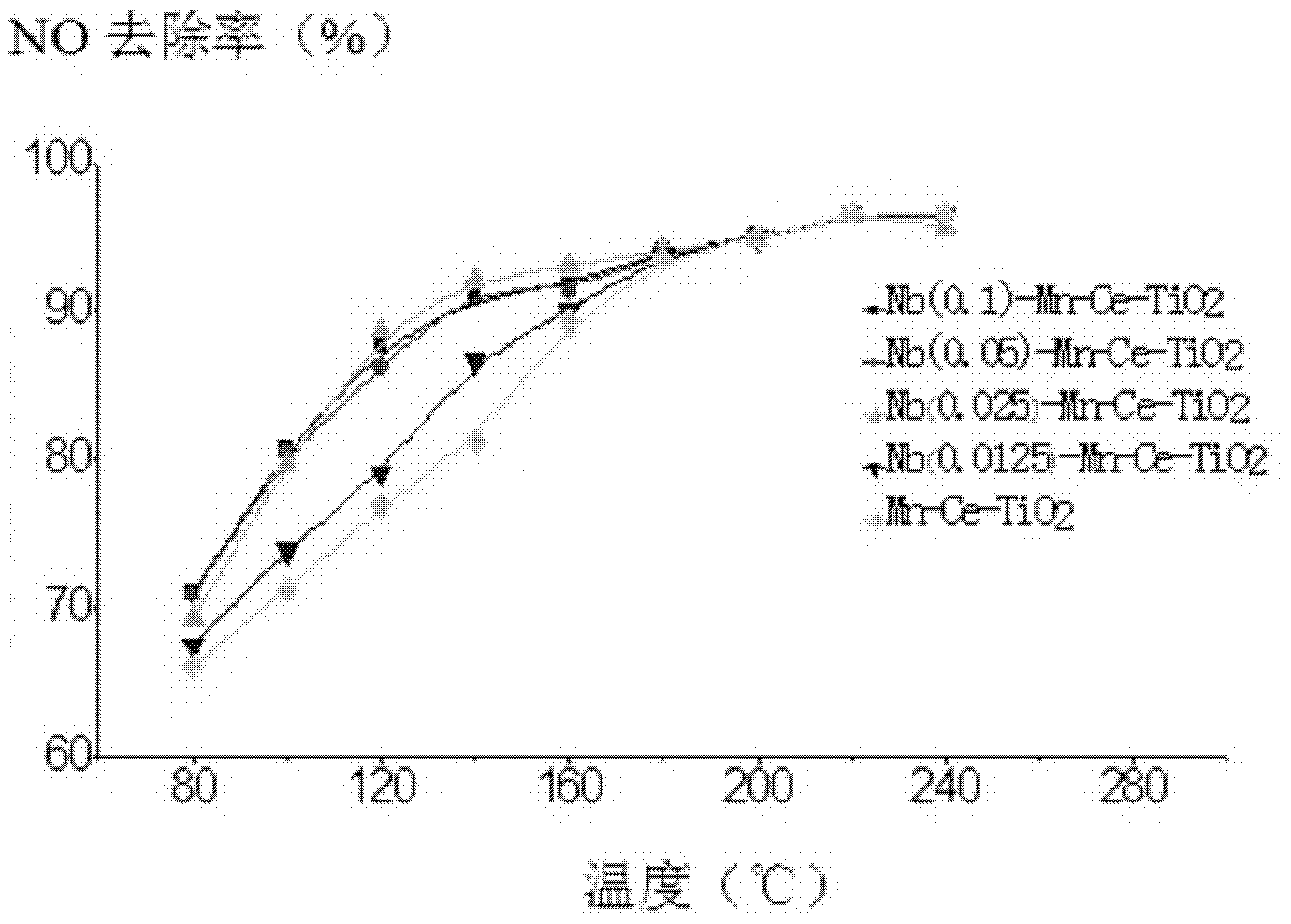

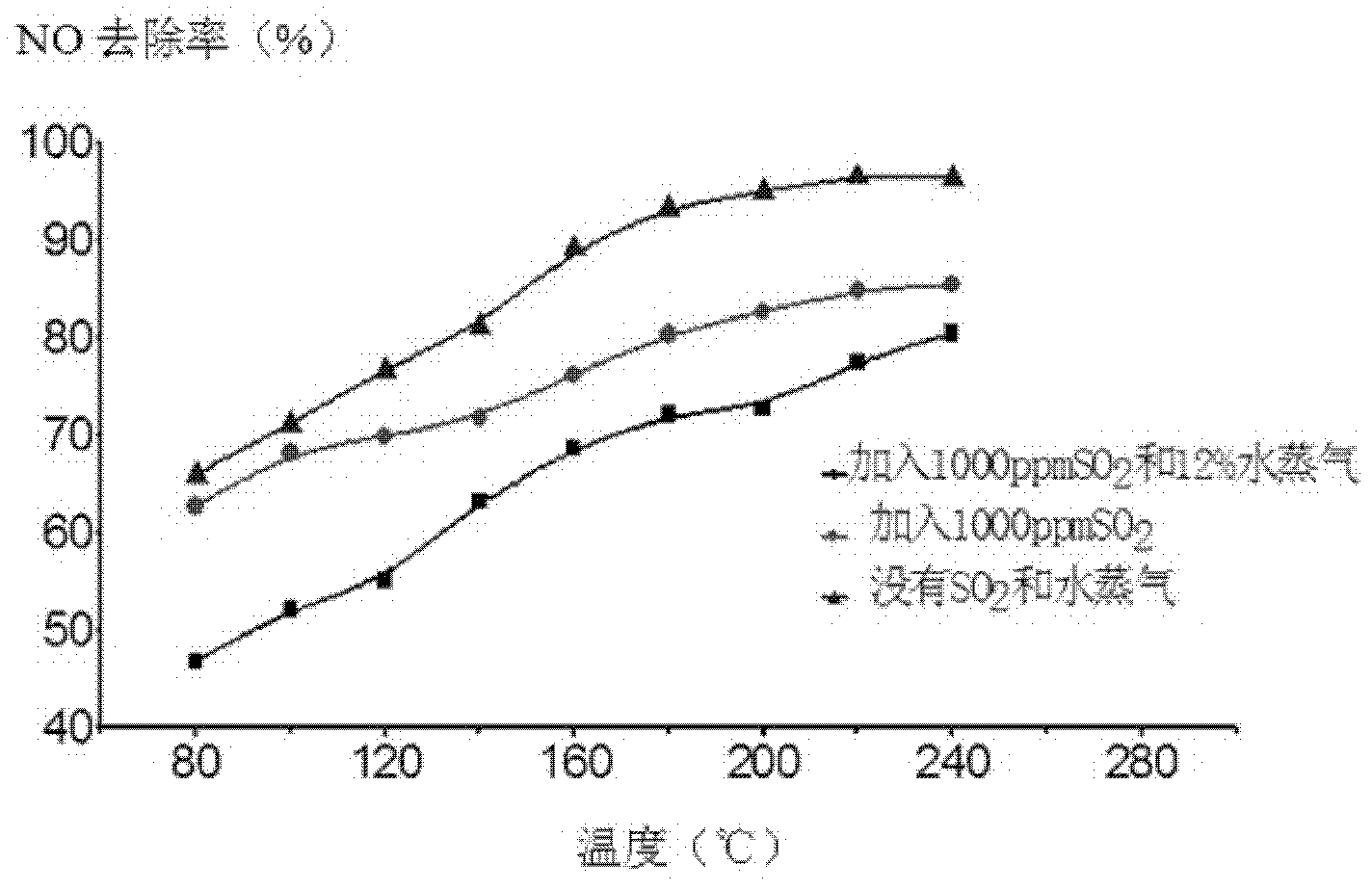

[0058] According to the results of the activity t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com