Terminal alkenyl polyether and preparation method and application thereof

An alkenyl-terminated polyether and copolymerization reaction technology, which is applied in the field of alkenyl-terminated polyether and its preparation, can solve the problems of cumbersome synthesis process and poor quality stability of polymerization products, and achieve simple process, high water reduction rate and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

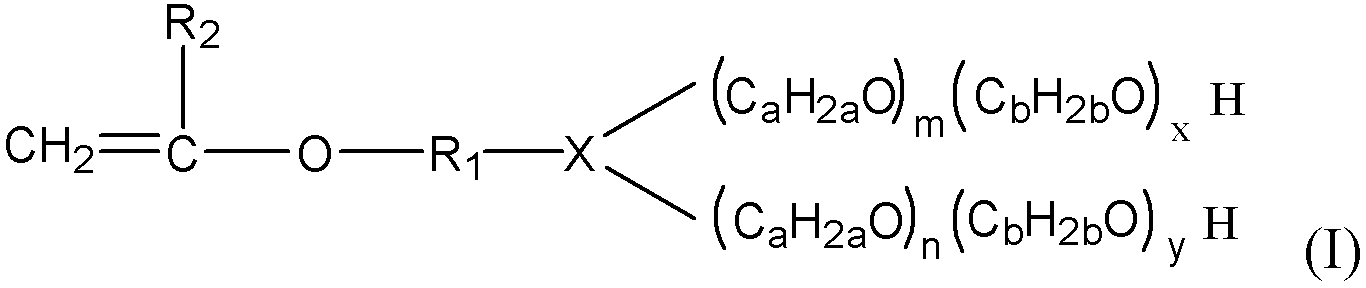

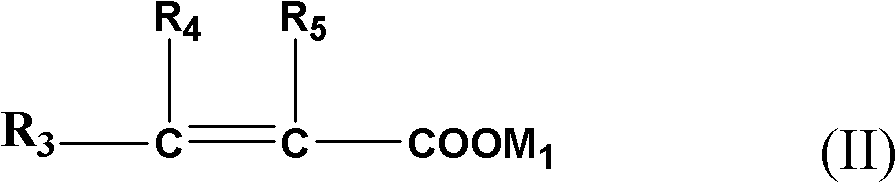

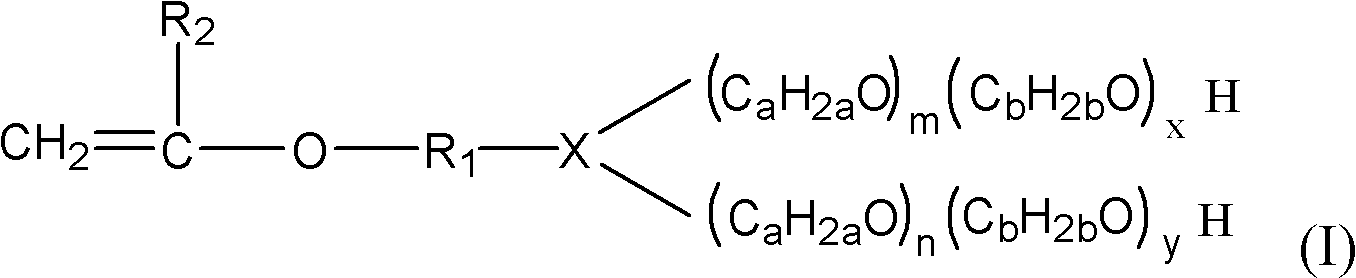

Method used

Image

Examples

Embodiment 1

[0063] In the reactor, add 20g of water and 15.8g of monomer A-1 (the weight-average molecular weight is 395), stir and heat to 30°C, then add 2.23g of 25% hydrogen peroxide, and dropwise add solution 1 (1.41g of hanging white block Mixture with 7.5g water) and solution 2 (mixture of 7.84g maleic anhydride and 16g water), keep the temperature at 30°C, add time for 2 hours, aging time for 1 hour, cool to normal temperature after the reaction, use mass Adjust the pH value to neutral with a 40% NaOH aqueous solution, add water, and discharge to obtain an alkenyl-terminated polyether (also known as polycarboxylate water reducer OX-JS-1). The solid content is 40%, and the weight average molecular weight is 16840.

[0064] Wherein the monomer A-1 used has the following structure:

[0065]

[0066] The structure of the finally obtained polycarboxylate water reducer is:

[0067]

Embodiment 2

[0069] In the reactor, add 154g of water and 124g of monomer A-2 (molecular weight is 2400), stir and heat to 40°C, then add 2.23g of 25% hydrogen peroxide, and drop solution 1 (1.27g of ascorbic acid and 7.5g of water mixture ) and solution 2 (the mixture of 14.4g acrylic acid and 17g water), the control temperature is 40 ℃, the time for adding drops is 2 hours, and the aging time is 1 hour. After the reaction is finished, it is cooled to normal temperature and adjusted with a NaOH aqueous solution with a mass concentration of 40%. pH value to neutral, replenish water, and discharge to obtain alkenyl-terminated polyether (also known as polycarboxylate water reducer OX-JS-2). The solid content is 40%, and the weight average molecular weight is 27500.

[0070] Wherein the monomer A-2 used has the following structure:

[0071]

[0072] The structure of the finally obtained polycarboxylate water reducer is:

[0073]

Embodiment 3

[0075] In the reactor, add 133g of water and 124g of monomer A-3 (molecular weight: 3436), stir and heat to 50°C, then add 3.15g of ammonium persulfate, and drop solution 1 (1.12g of sodium bisulfite and 7.5g of water mixture) and solution 2 (the mixture of 9.3g methacrylic acid and 17g water), the temperature is controlled at 50 ℃, the time for dropping is 2.5 hours, and the aging time is 1 hour. NaOH aqueous solution to adjust the pH value to neutral, replenish water, and discharge to obtain terminal alkenyl polyether (also known as polycarboxylate water reducer OX-JS-3). The solid content is 40%, and the weight average molecular weight is 33910.

[0076] Wherein the monomer A-3 used has the following structure:

[0077]

[0078] The structure of the finally obtained polycarboxylate water reducer is:

[0079]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com