Preparation technology of antioxidant and conductive spinel coating

A spinel coating and preparation process technology, applied in metal material coating process, coating and other directions, can solve the problems of difficult to control the thickness of continuous layers, inability to precisely control the coating, difficult to precisely control the alloy layer, etc. The effect of meeting the protection needs, broadening the application range and preventing the volatilization of Cr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

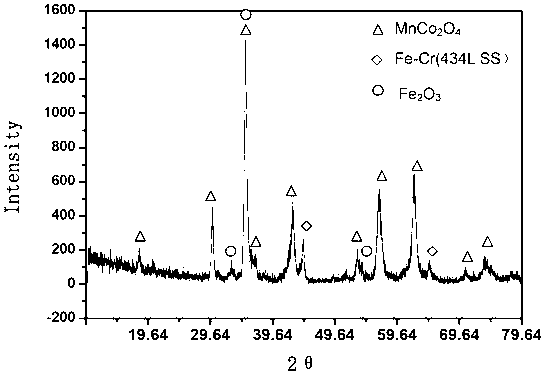

Image

Examples

Embodiment 1

[0023] 1): The preparation process of the spin deposition electrode: Weigh 25.88g of Co metal (purity greater than 99.9wt.%) and 24.12g of manganese metal (purity: greater than 99.9wt.%), mix and smelt it into a 50g metal ingot, and then The metal ingot was placed in a tube furnace for vacuum annealing at a temperature of 900°C for 60 hours, so that the internal structure of the alloy was homogenized, and the atomic ratio of Co:Mn in the alloy was 1:1. Then make it into a round rod with a diameter of about 4mm, clean it with ultrasonic-assisted degreasing in acetone solution for 3-5min, then rinse it with deionized water, and dry it for later use.

[0024] 2): The pretreatment process of the deposited metal sample: use 400-1200 # Grind the sample step by step with a suitable sandpaper, put the sample in an acetone solution for ultrasonic-assisted degreasing and cleaning for 3 to 5 minutes, then rinse with deionized water, and dry it for later use.

[0025] 3): The preparation...

Embodiment 2

[0027] 1): The preparation process of the spin deposition electrode: Weigh 40.55g of Co metal (purity greater than 99.9wt.%) and 9.45g of manganese metal (purity: greater than 99.9wt.%), mix them evenly and then smelt them, and then smelt the smelted metals The ingot was put into a tube furnace for vacuum annealing, the annealing temperature was 1100°C, and the time was 40h, so that the internal structure of the alloy was homogenized, and the Co:Mn atomic ratio of the alloy was 4:1. Then make it into a round rod with a diameter of about 2mm, clean it with ultrasonic-assisted degreasing in acetone solution for 3-5min, then rinse it with deionized water, and dry it for later use.

[0028] 2): The pretreatment process of the deposited metal sample: use 400-1200 # Grind the sample step by step with a suitable sandpaper, put the sample in an acetone solution for ultrasonic-assisted degreasing and cleaning for 3 to 5 minutes, then rinse with deionized water, and dry it for later use...

Embodiment 3

[0031] 1): The preparation process of the spin deposition electrode: Weigh 25.88g of Co metal (purity greater than 99.9wt.%) and 24.12g of manganese metal (purity: greater than 99.9wt.%), mix them evenly and then smelt them, and then smelt the smelted metals The ingot was placed in a tube furnace for vacuum annealing at a temperature of 1100°C for 60 hours, so that the internal structure of the alloy was homogenized, and the atomic ratio of Co:Mn in the alloy was 1:1. Then make it into a round rod with a diameter of about 2mm, clean it with ultrasonic-assisted degreasing in acetone solution for 3-5min, then rinse it with deionized water, and dry it for later use.

[0032] 2): The pretreatment process of the deposited metal sample: use 400-1200 # Grind the sample step by step with a suitable sandpaper, put the sample in an acetone solution for ultrasonic-assisted degreasing and cleaning for 3 to 5 minutes, then rinse with deionized water, and dry it for later use.

[0033]3): ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com