Solar battery doped region forming method

A technology of solar cells and doped regions, applied in the field of photovoltaic doping, can solve the problems of high activation cost, complicated process, high quality requirements of silicon wafers, etc., and achieve the effects of simplified process conditions, low temperature and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The method for forming the doped region of the solar cell

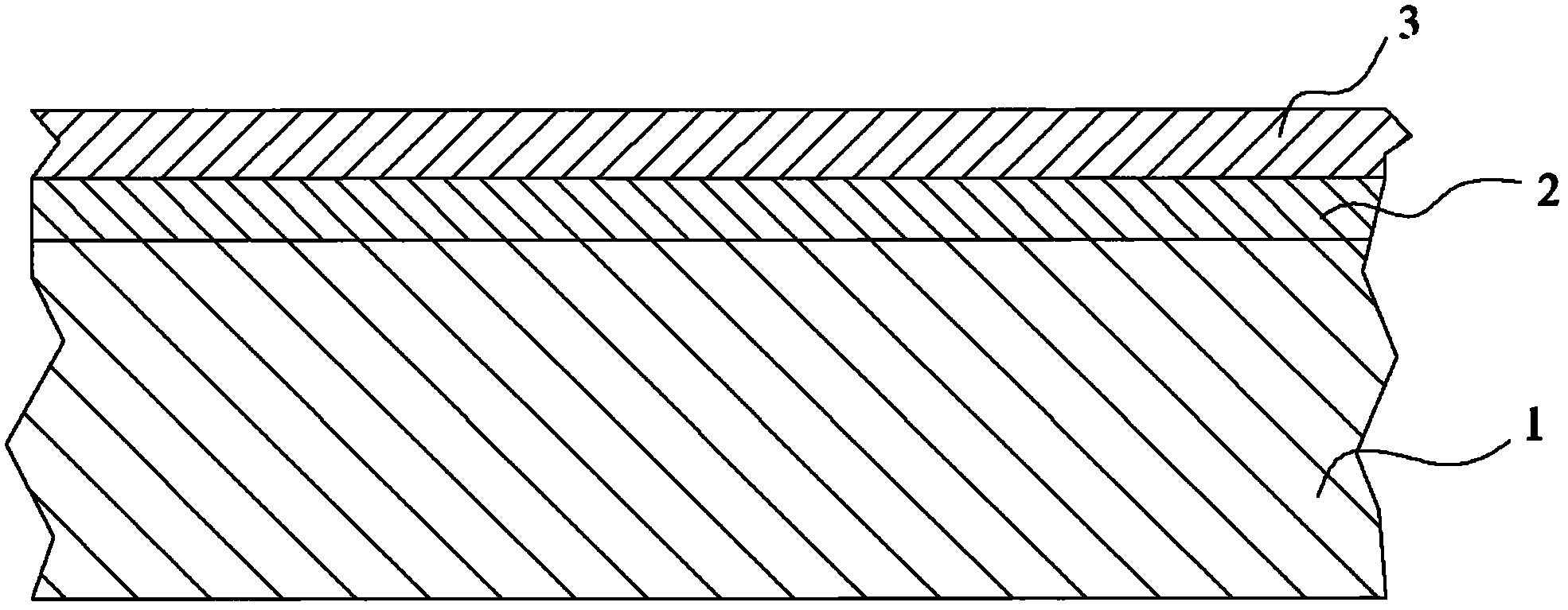

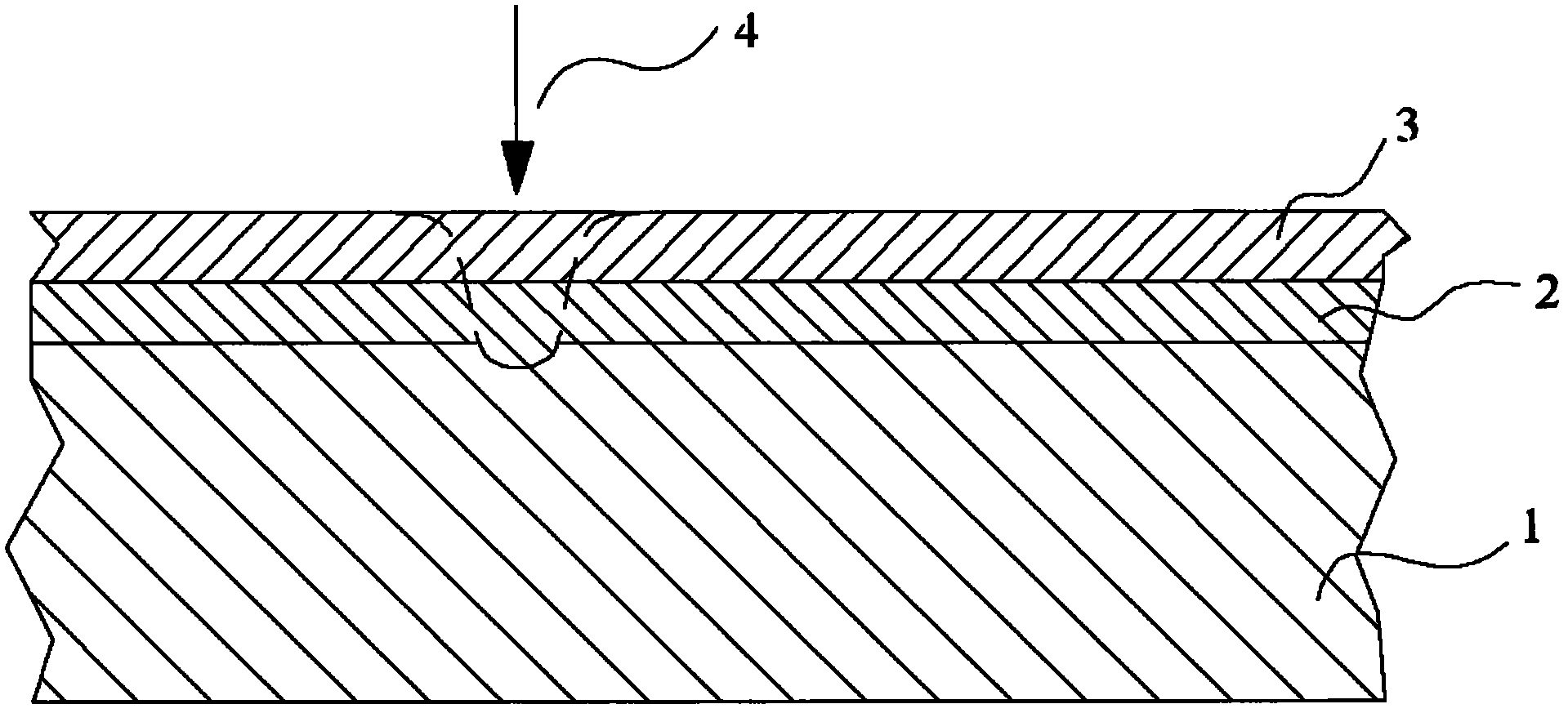

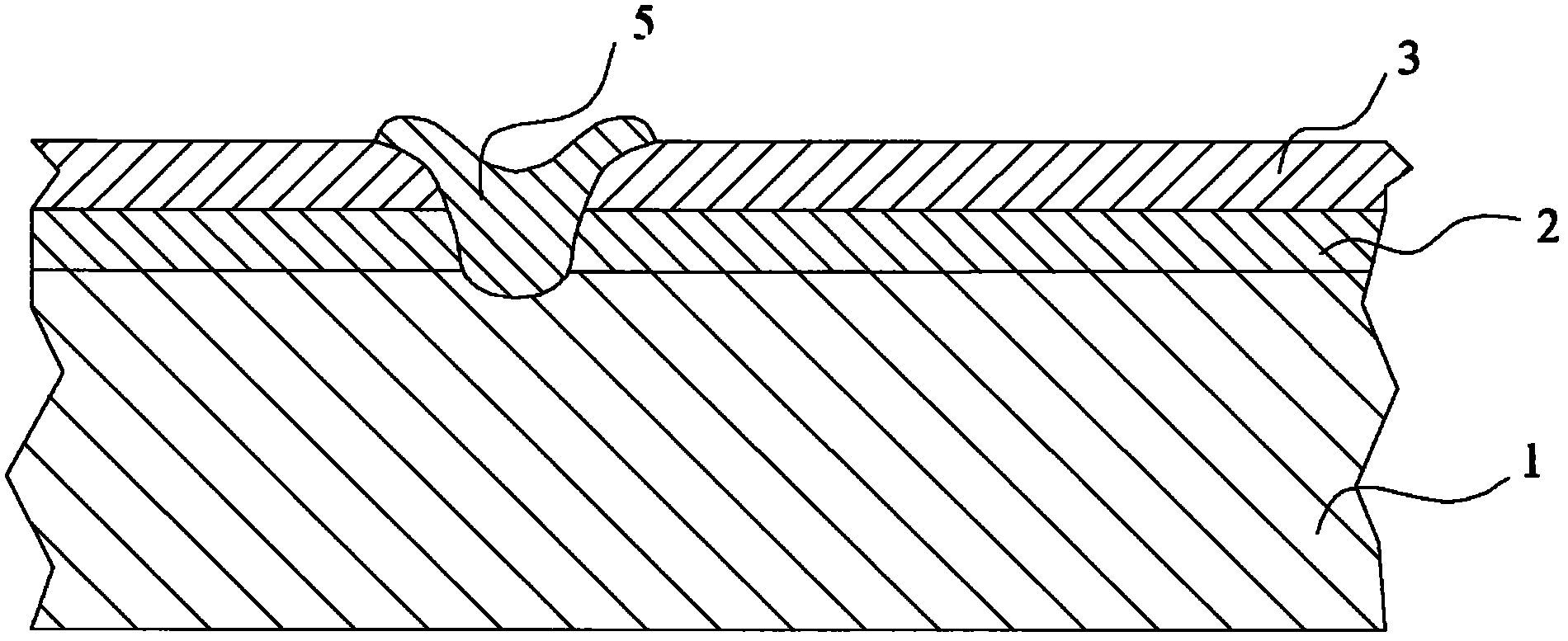

[0039] See attached figure 1 , attached figure 2 And attached image 3 As shown, a method for forming a doped region of a solar cell is used to prepare a selective emitter solar cell, and the specific operation steps are:

[0040] ①. Select a P-type single crystal silicon wafer 1 with a resistivity of 0.5-3Ω·cm. In a mixed solution of NaOH and isopropanol, at a temperature of 90°C, etch the surface of the silicon wafer to obtain a uniform size. After the suede surface, soak it in dilute hydrochloric acid and hydrofluoric acid solution for 5 minutes, and finally rinse it with deionized water and dry it.

[0041] ②, using a conventional diffusion furnace (conventional thermal diffusion process), using phosphorus oxychloride (POCl 3 ) Diffusion of phosphorus on the surface of the silicon wafer. During the diffusion, the silicon wafers are placed back to back on the quartz boat. The constant temp...

Embodiment 2

[0053] Embodiment 2, the method for forming the doped region of the solar cell

[0054] See attached Figure 4 , attached Figure 5 And attached Image 6 As shown, a method for forming a doped region of a solar cell, the back contact structure of the solar cell prepared by this method, the specific operation steps are:

[0055] ①. According to the steps ①, ②, and ③ in Example 1, silicon wafers were prepared.

[0056] ②, as attached Figure 4 As shown, a layer of silicon dioxide is formed on the back surface of the P-type single crystal silicon wafer 1 as the passivation layer 3 . This step is to form a passivation layer on the surface (whole surface) of a semiconductor substrate (silicon wafer).

[0057] ③. Perform ion implantation of boron (B) dopant on the back surface of the silicon wafer, and the dopant may also be aluminum (Al), gallium (Ga), or indium (In) of the same family as boron. This step is to use ion implantation to pass through the passivation layer (silic...

Embodiment 3

[0063] Embodiment 3, the method for forming the doped region of the solar cell

[0064] Laser activation is used to simultaneously prepare the selective emitter (the method is the same as in Example 1) and the back partial contact (the method is the same as in Example 2).

[0065] On the basis of the above two embodiments, a solar cell with both a front selective emitter and a rear partial contact structure can be formed on a silicon wafer. The schematic diagram of its structure is shown in the attached Figure 7 shown.

[0066] The power of the laser used is 3W; the speed of the laser is 5000mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com