Pt/Fe3O4-CeO2 composite material and its preparation method and use

A fe3o4-ceo2, composite material technology, applied in the direction of material electrochemical variables, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of weak conductivity, poor catalytic activity, etc., achieve low cost, reduce solubility, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

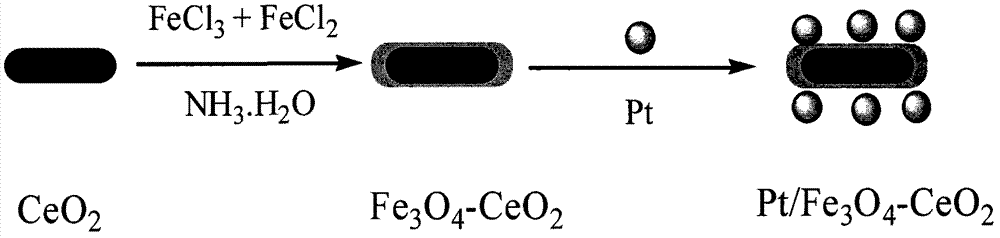

[0021] see figure 1 , showing the Pt / Fe of the embodiment of the present invention 3 o 4 -CeO 2 A method for preparing a composite material, the method comprising the steps of:

[0022] S01: Nano-CeO 2 Disperse in water with a concentration of 0.10-0.15mol / L, vibrate ultrasonically, add concentrated hydrochloric acid and soluble Fe to the solution in sequence 3+ Salt and Fe 2+ salt, to obtain a mixed system, wherein the mass of concentrated hydrochloric acid is CeO 2 2% by mass of aqueous solution, Fe 3+ Salt and Fe 2+ The molar ratio of salt is 2:1, Fe 3+ The concentration of salt in the system is 0.8-1.0mol / L;

[0023] S02: Add ammonia solution to the above mixing system and continue to stir for 20 to 40 minutes to obtain Fe 3 o 4 -CeO 2 nanocomposites;

[0024] S03: the Fe 3 o 4 -CeO 2 The nanocomposite material is prepared into a dispersion liquid with a mass concentration of 2.0mg / mL~2.5mg / mL, and mixed with H 2 PtCl 4 The aqueous solution was mixed, and...

Embodiment 1

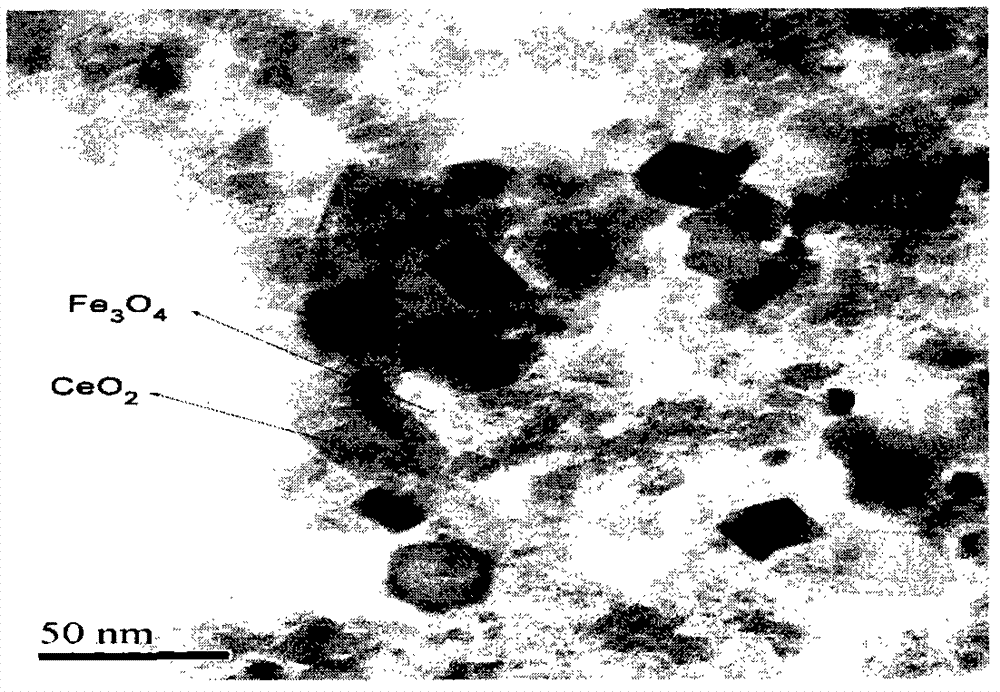

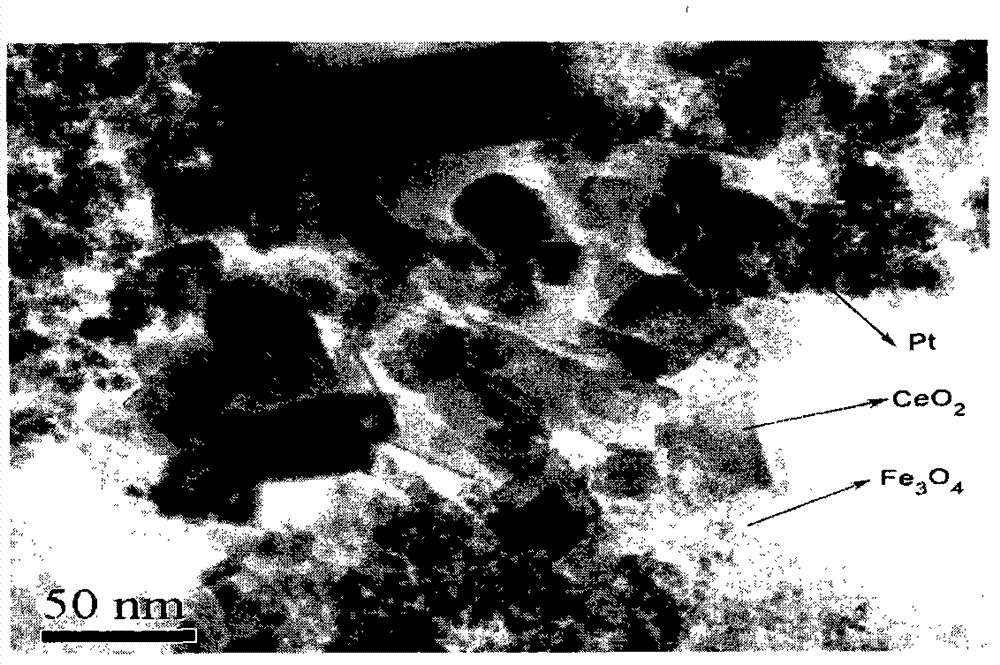

[0033] 20mg CeO 2 Disperse in 20mL water to make the concentration 1mg / mL, ultrasonically shake for 30 minutes, then add 0.4mL concentrated hydrochloric acid, 216mg FeCl 3 ·6H 2 O and 80 mg FeCl 2 4H 2 O, sonicate to make it evenly mixed, then slowly add 100mL of 1mol / L ammonia solution to the above system, stir mechanically for 30 minutes, and centrifuge to obtain Fe 3 o 4 -CeO 2 nanocomposites. The above-prepared Fe 3 o 4 -CeO 2 The nanocomposites were dispersed in 5 mL double-distilled water, and 2 mL H 2 PtCl 4 (1%, w / w) solution and mix well. Slowly add 1mL NaBH 4 (5%, w / w) solution H 2 PtCl 4 Reduction to Pt nanoparticles. At this time, Pt nanoparticles supported on Fe 3 o 4 -CeO 2 surface. Precipitate by centrifugation to get Pt / Fe 3 o 4 -CeO 2 composite material.

Embodiment 2

[0035] First, the glassy carbon electrode (GC, 3-mm in diameter) was polished in sandpaper and alumina slurry, then ultrasonically cleaned in acetone and ethanol for 5 min, and finally ultrasonically cleaned with distilled water to obtain a bare glassy carbon electrode with a clean surface. The synthesized Pt / Fe 3 o 4 -CeO 2 Disperse in water and disperse by 10-min short-term ultrasonic dispersion to form a uniform dispersion with a concentration of 1 mg / mL. Drop 6 μL of dispersion solution on the surface of a clean bare glassy carbon electrode, and obtain Pt / Fe after the water evaporates naturally at room temperature 3 o 4 -CeO 2 Modified electrodes. The counter electrode is a platinum electrode, and the reference electrode is a saturated calomel electrode, forming a three-electrode electrochemical system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com