A kind of preparation method of graphene and reduced graphene oxide composite film

A graphene composite and graphene film technology, applied in the field of nanomaterial preparation and application, can solve the problems of limited application, poor adhesion, easy surface oxidation, etc., and achieve high flexibility, high light transmittance, and simple preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

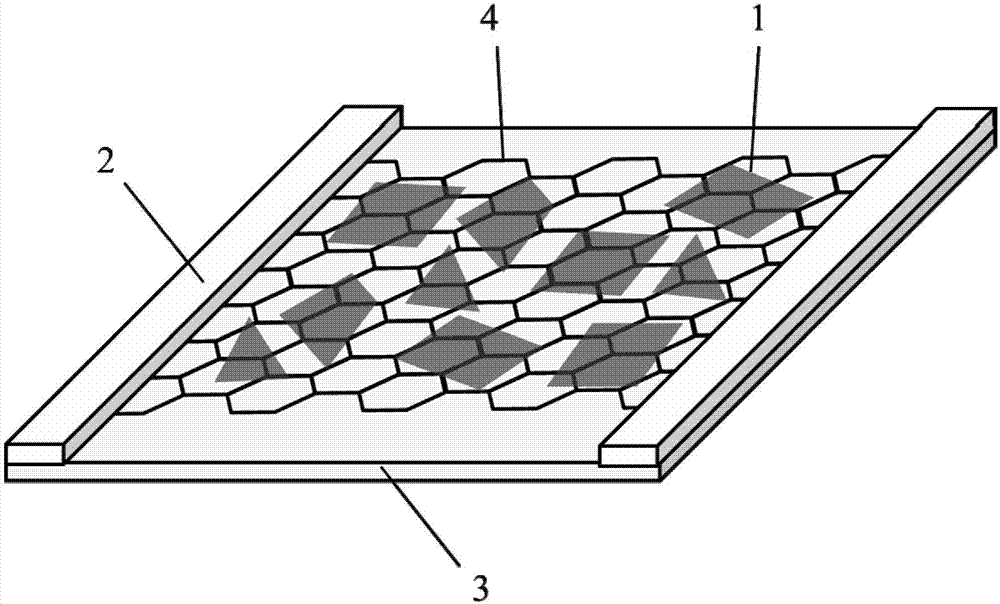

[0019] A kind of preparation method of graphene and reduced graphene oxide composite film is characterized in that comprising the following steps:

[0020] 1) Immerse the substrate with the graphene film attached in the PDDA aqueous solution, soak it, rinse it with water after taking it out, and obtain the graphene film with PDDA molecules adsorbed; the volume mass concentration of the PDDA aqueous solution is 10g / L-30g / L, and the soaking time 10min to 30min, the substrate of the graphene film can be quartz, glass or silicon wafer;

[0021] 2) Immerse the graphene film with PDDA molecules adsorbed in step 1) in the graphene oxide aqueous solution, soak it, take it out and rinse it with water to obtain a graphene and graphene oxide composite film; the volume mass fraction of the graphene oxide aqueous solution is 0.05 mg / mL-1mg / mL, soaking time is 10min~30min,

[0022] 3) Dry the formed graphene and graphene oxide composite film, and then place it in a protective atmosphere t...

Embodiment 1

[0025] This embodiment includes the following steps:

[0026] 1) Immerse the quartz sheet with graphene attached in PDDA aqueous solution (20g / L, pH=9), soak for 20min, take it out and rinse with water to obtain a graphene film with PDDA molecules adsorbed;

[0027] 2) Immerse the graphene film on which PDDA molecules are adsorbed in step 1) in a graphene oxide aqueous solution (0.05 mg / mL, pH=9), soak for 20 minutes, take it out and rinse it with water to obtain a composite film of graphene and graphene oxide;

[0028] 3) Blow dry the formed graphene and graphene oxide composite film with nitrogen, and then fully reduce it in an argon atmosphere at 300° C. to obtain a composite film of graphene and reduced graphene oxide.

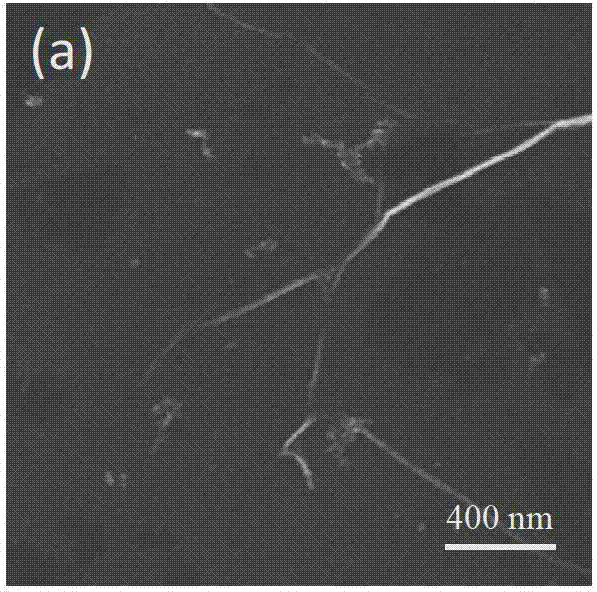

[0029] Figure 2a A scanning electron micrograph of the graphene and reduced graphene oxide composite film prepared in this example, a small amount of reduced graphene oxide flakes are attached on the graphene film. The resistance-temperature variation c...

Embodiment 2

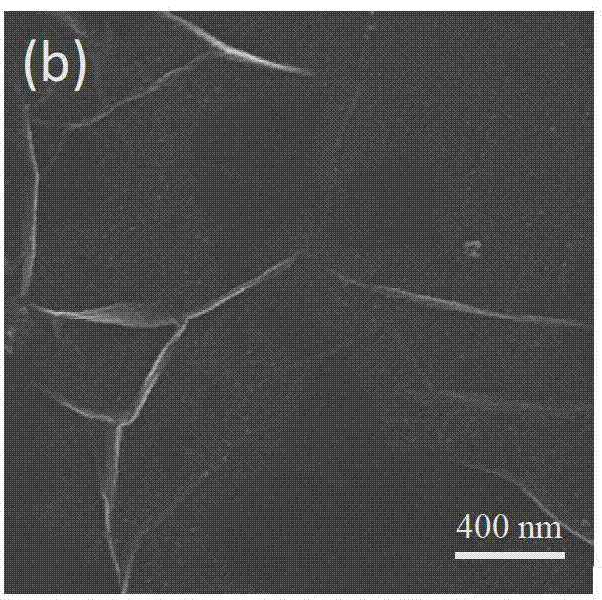

[0031] This embodiment includes the following steps:

[0032] 1) Immerse the glass sheet with graphene attached in PDDA aqueous solution (30g / L, pH=9), soak for 10min, take it out and rinse with water to obtain a graphene film with PDDA molecules adsorbed;

[0033] 2) Immerse the graphene film with PDDA molecules adsorbed in step 1) in a graphene oxide aqueous solution (0.1mg / mL, pH=9), soak for 30min, take it out and rinse with water to obtain a composite film of graphene and graphene oxide;

[0034] 3) Blow dry the formed graphene and graphene oxide composite film with nitrogen, and then place it in a nitrogen atmosphere at 600°C for full reduction to obtain a composite film of graphene and reduced graphene oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com