Toughened polylactic acid and preparation method of same

A polylactic acid and toughening technology, applied in the field of toughening polylactic acid and its preparation, can solve the problems of PLA material not having stability, low elongation at break, widely used, loss of plasticizing effect, etc., to overcome the migration and precipitation behavior. , high toughness, the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the polyethylene glycol-dibasic acid-lactide specifically can be prepared according to the following method:

[0026] The dibasic acid or its anhydride, polyethylene glycol and lactide are reacted under the action of a catalyst to obtain a ternary copolymer of polyethylene glycol-dibasic acid-lactide.

[0027] As a preferred version, the preparation method of the terpolymer of polyethylene glycol-diacid-lactide is specifically:

[0028] Mix dibasic acid or its anhydride with polyethylene glycol, heat up to 70-100°C to dissolve and stir evenly, then add lactide, and finally add catalyst, after reaction, dehydrate under high vacuum at 130-170°C to obtain polyethylene glycol - Terpolymers of dibasic acid-lactide.

[0029] The preparation method of the polyethylene glycol-dibasic acid-lactic acid can be prepared according to the following method:

[0030] The dibasic acid or its anhydride, polyethylene glycol and lactic acid are reacted under the...

Embodiment 1

[0040] Drying treatment of polyethylene glycol After strict drying treatment, the ground three-neck bottle equipped with a magnetic stirrer and a thermometer was weighed. Add about 250g of polyethylene glycol 400 (PEG-400) into the three-neck bottle and seal it, leaving only the vacuum interface, stir and heat with a heating mantle with an electromagnetic stirrer, slowly raise the temperature to 130°C, dehydrate under high vacuum, and the solution Dehydration for 2 hours after bubbles are no longer generated in the medium, and then cooled to below 90 ° C, the vacuum is released under the protection of nitrogen, weighed, and the mass of PEG-400 is accurately calculated.

[0041] Synthesis of polyether polyester Add succinic anhydride (SA) with equimolar mass to PEG-400 in a three-neck flask and stir for 10 minutes, then add SnCl with a molar mass of SA of 0.3% 2 , control the reaction temperature at 90°C, react for 16 hours, slowly raise the temperature to 150°C, and dehydrate ...

Embodiment 2

[0045] The drying treatment of Polyethylene Glycol is with embodiment 1.

[0046] Synthesis of polyether polyester Add succinic anhydride (SA) with equimolar mass to PEG-400 in a three-neck flask and stir for 10 minutes, then add SnCl with a molar mass of SA of 0.3% 2 , control the reaction temperature at 90°C, react for 16 hours, slowly raise the temperature to 150°C, and dehydrate under high vacuum for 24 hours. The weight average molecular weight of the obtained polyether polyester is 23kg / mol, and the molecular weight distribution index is 1.9. Store it in a sealed glass reagent for later use , labeled PES2.

[0047] Blend ratio PLA, PES2 and ADR-4370-S were melt blended at mass ratios of 90:10:0.4, 80:20:0.4 and 70:30:0.4; the preparation of the blend was the same as in Example 1.

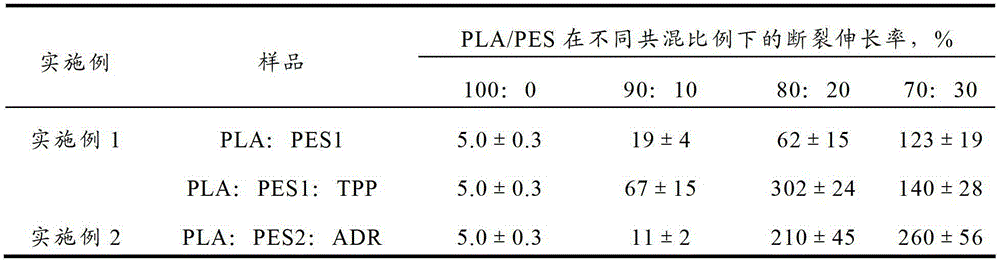

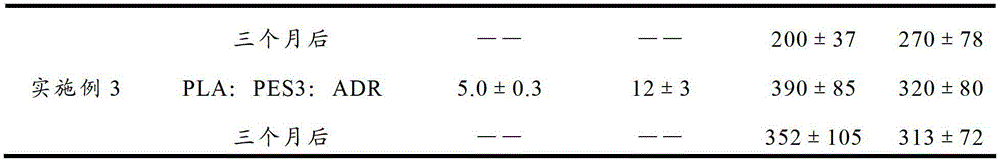

[0048] The elongation at break of the blends of PLA and PES2 is shown in Table 1. Table 1 contains the data of the elongation at break of the blends of PLA and PES2, and also includes the elo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com