High-temperature resistant, anti-sticking and anticorrosive thermoplastic coating for inner walls of metal pipelines and preparation method thereof

A technology for anti-corrosion coatings and high temperature resistance, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., to achieve the effects of low friction coefficient, simple preparation method, and easy-to-control production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 20 grams of thermoplastic polyethersulfone resin with a logarithmic inherent viscosity of 0.31, 12 grams of polyperfluoroethylene propylene micropowder, 8 grams of iron red pigment, 50 grams of N-methylpyrrolidone, 6 grams of methyl ethyl ketone, 20 grams of toluene, 4 grams After mixing with 1 g xylene, the mixture is stirred at a linear speed of 15 m / s for 15 minutes and then sanded for 2 hours to obtain a thermoplastic high temperature resistant anti-sticking and anti-corrosion coating for the inner wall of a metal pipe.

[0028] The inner wall of the metal pipe is coated with a thermoplastic high temperature resistant anti-stick and anti-corrosion coating to the inner wall of the metal pipe by air spraying.

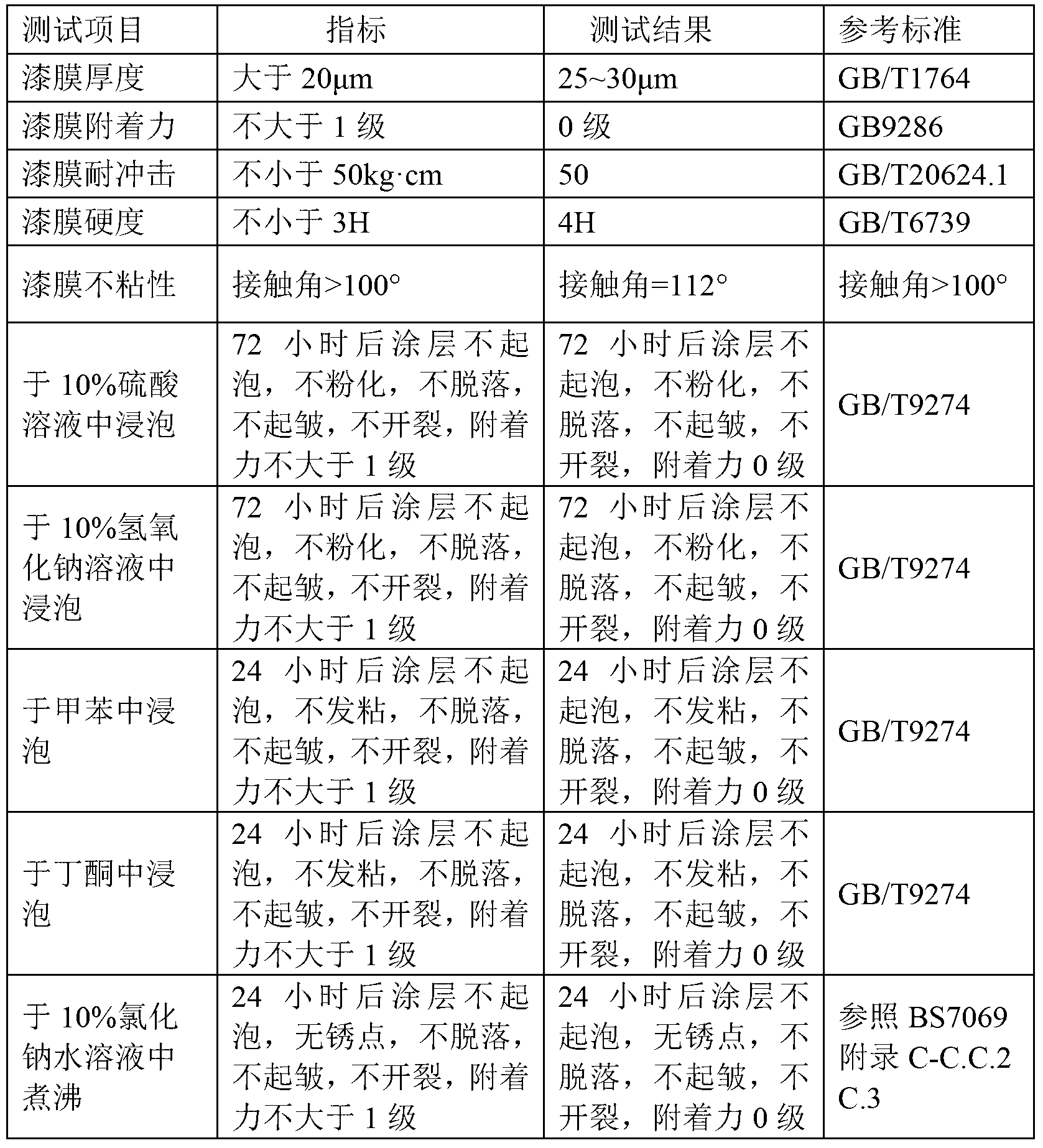

[0029] The coating properties are as follows:

[0030]

Embodiment 2

[0032] 30 grams of thermoplastic polyethersulfone resin with a logarithmic inherent viscosity of 0.35, 12 grams of polytetrafluoroethylene micropowder, 1 gram of organic bentonite, 4 grams of iron black pigment, 1.4 grams of mica flakes, 1.4 grams of graphite, 20 grams of N-methyl pyrrolidone, 60 grams of N,N dimethylacetamide, 12 grams of methyl ethyl ketone, 60 grams of toluene and 0.2 grams of silicone leveling agent were mixed, stirred at a linear speed of 15 m / s for 15 minutes, and then sanded for 4 hours to obtain metal Thermoplastic high temperature resistant anti-stick and anti-corrosion coating for the inner wall of the pipeline.

[0033] The inner wall of the metal pipe is coated with a thermoplastic high temperature resistant anti-stick and anti-corrosion coating to the inner wall of the metal pipe by air spraying.

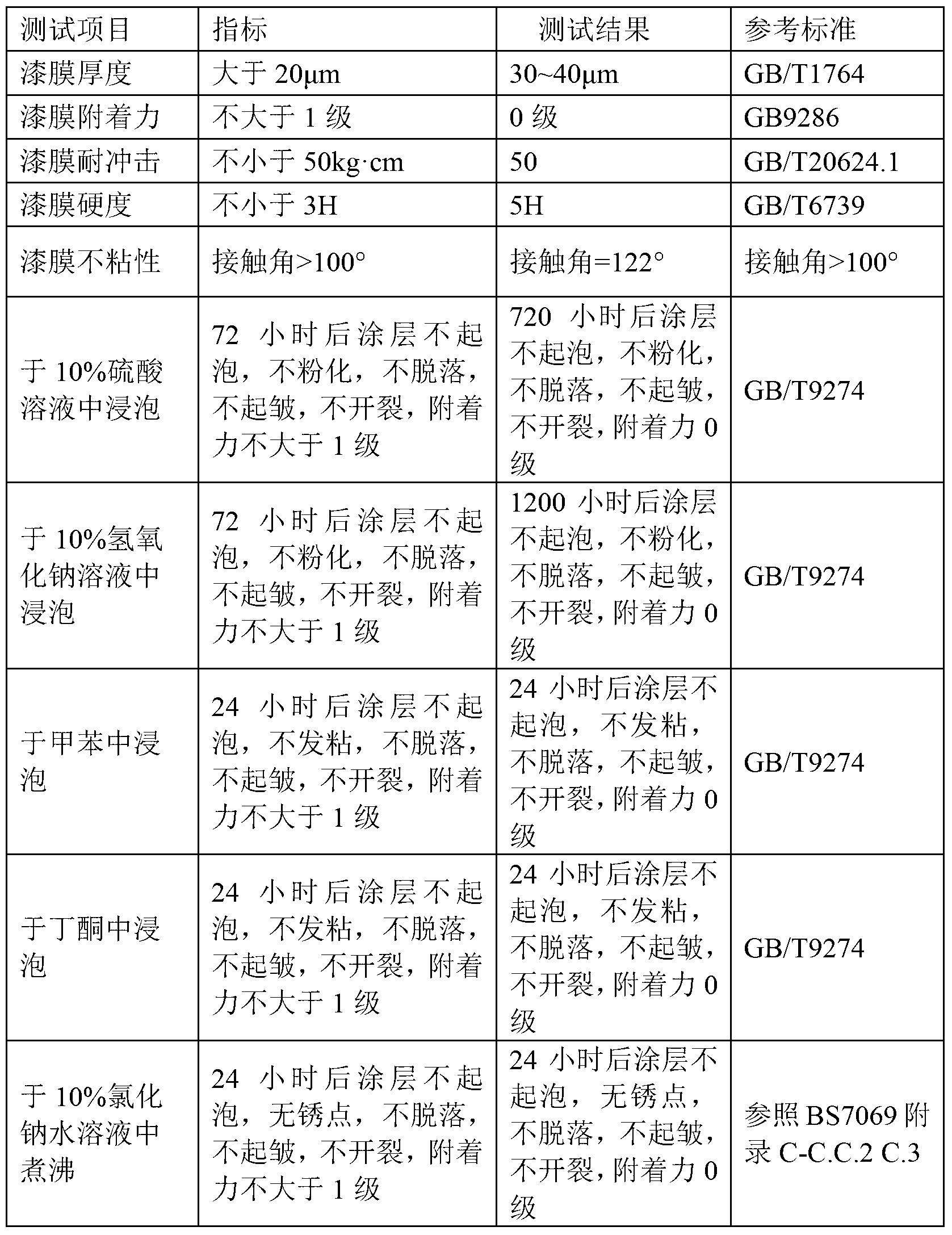

[0034] The coating properties are as follows:

[0035]

Embodiment 3

[0037] 40 grams of thermoplastic polyethersulfone resin with a logarithmic inherent viscosity of 0.37, 30 grams of tetrafluoroethylene-perfluorovinyl ether copolymer micropowder, 4 grams of fumed silica, 12 grams of titanium dioxide and 18 grams of iron blue pigment, 40 grams g of barium sulfate, 20 g of calcium carbonate whiskers, 24 g of N-methylpyrrolidone, 67 g of N,N dimethylformamide, 6 g of cyclohexanone, 15 g of methyl ethyl ketone, 2 g of toluene, 42 g of trimethylbenzene and 4 grams of silicone leveling agent was mixed, stirred at a linear speed of 15 m / s for 30 minutes, and then sanded for 6 hours to obtain a thermoplastic high temperature resistant anti-sticking and anti-corrosion coating for the inner wall of a metal pipe.

[0038] The inner wall of the metal pipe is coated with a thermoplastic high temperature resistant anti-stick and anti-corrosion coating to the inner wall of the metal pipe by air spraying.

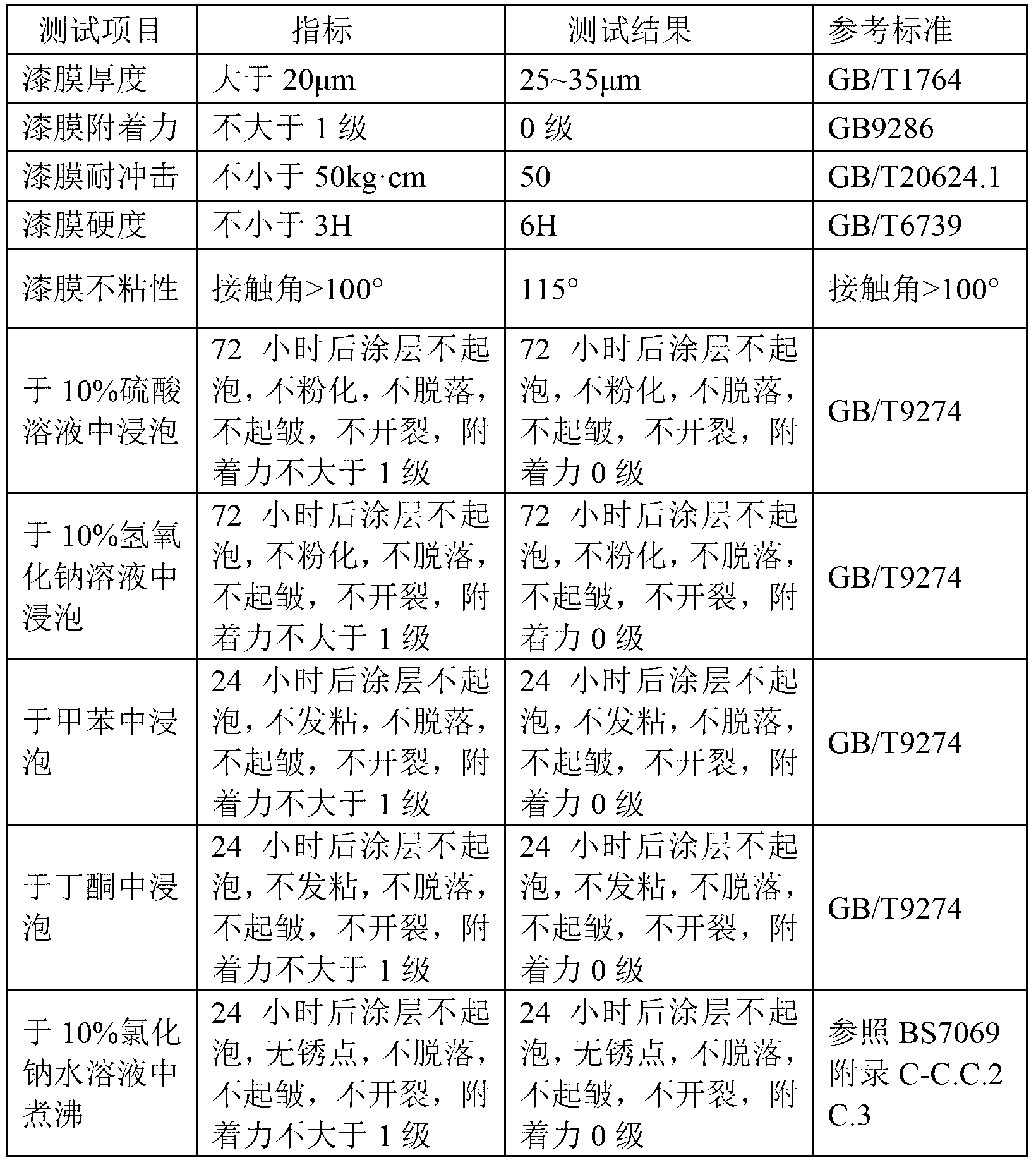

[0039] The coating properties are as follows:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com