Thermoplastic high-temperature-resistant anti-sticking anti-corrosion coating for inner wall of metal pipeline and preparation method thereof

A technology of anti-corrosion coating and high temperature resistance, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., to achieve the effect of reducing interaction force, easy control of production process and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 20 grams of thermoplastic polyethersulfone resin with a logarithmic reduced viscosity of 0.31, 12 grams of polyperfluoroethylene propylene micropowder, 8 grams of iron red pigment, 50 grams of N-methylpyrrolidone, 6 grams of butanone, 20 grams of toluene, 4 After mixing 1 g of xylene, stir at a linear speed of 15 m / s for 15 minutes and then sand mill for 2 hours to obtain a thermoplastic high-temperature-resistant anti-sticking anti-corrosion coating for the inner wall of a metal pipe.

[0028] The inner wall of the metal pipe is coated on the inner wall of the metal pipe with a thermoplastic high temperature resistant anti-stick anti-corrosion paint by air spraying.

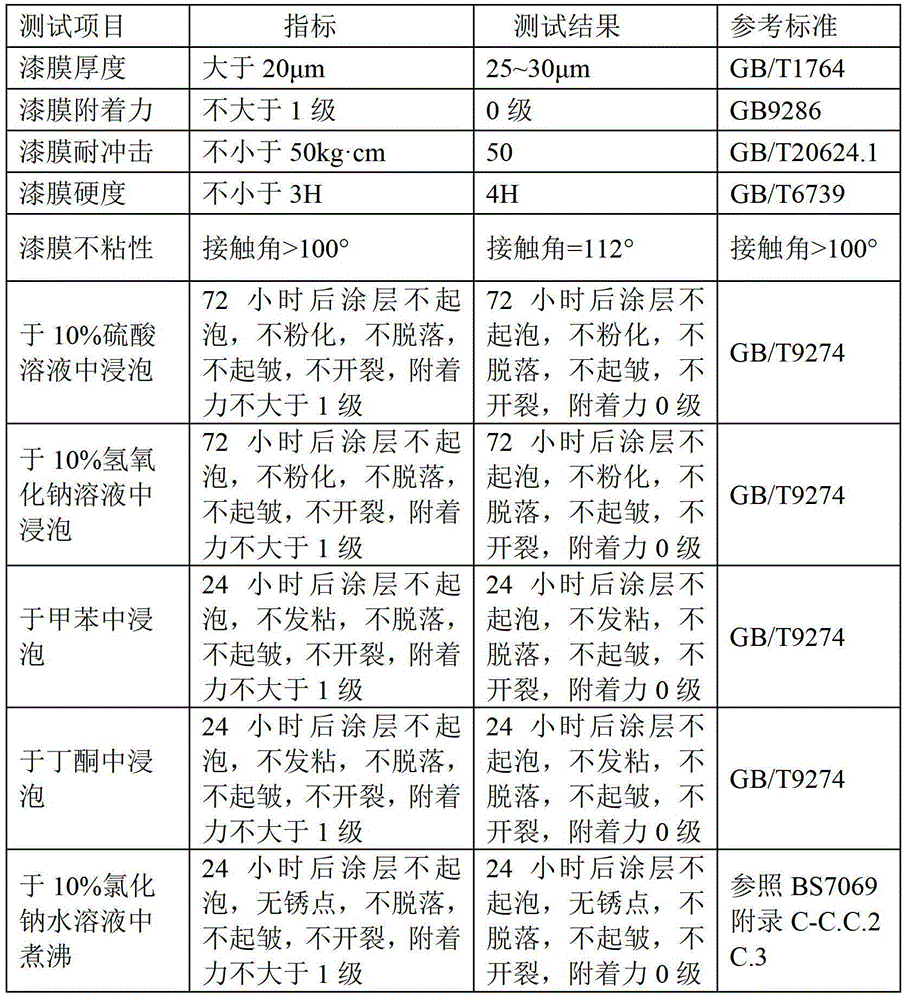

[0029] The coating properties are as follows:

[0030]

Embodiment 2

[0032] 30 grams of thermoplastic polyethersulfone resin with a logarithmic viscosity of 0.35, 12 grams of polytetrafluoroethylene micropowder, 1 gram of organic bentonite, 4 grams of iron black pigment, 1.4 grams of mica flakes, 1.4 grams of graphite, and 20 grams of N-formaldehyde Base pyrrolidone, 60 grams of N,N dimethylacetamide, 12 grams of butanone, 60 grams of toluene and 0.2 grams of silicone leveling agent were mixed and stirred at a linear speed of 15 m / s for 15 minutes and then sanded for 4 hours to obtain a metal The inner wall of the pipeline is made of thermoplastic high temperature resistant anti-stick anti-corrosion coating.

[0033] The inner wall of the metal pipe is coated on the inner wall of the metal pipe with a thermoplastic high temperature resistant anti-stick anti-corrosion paint by air spraying.

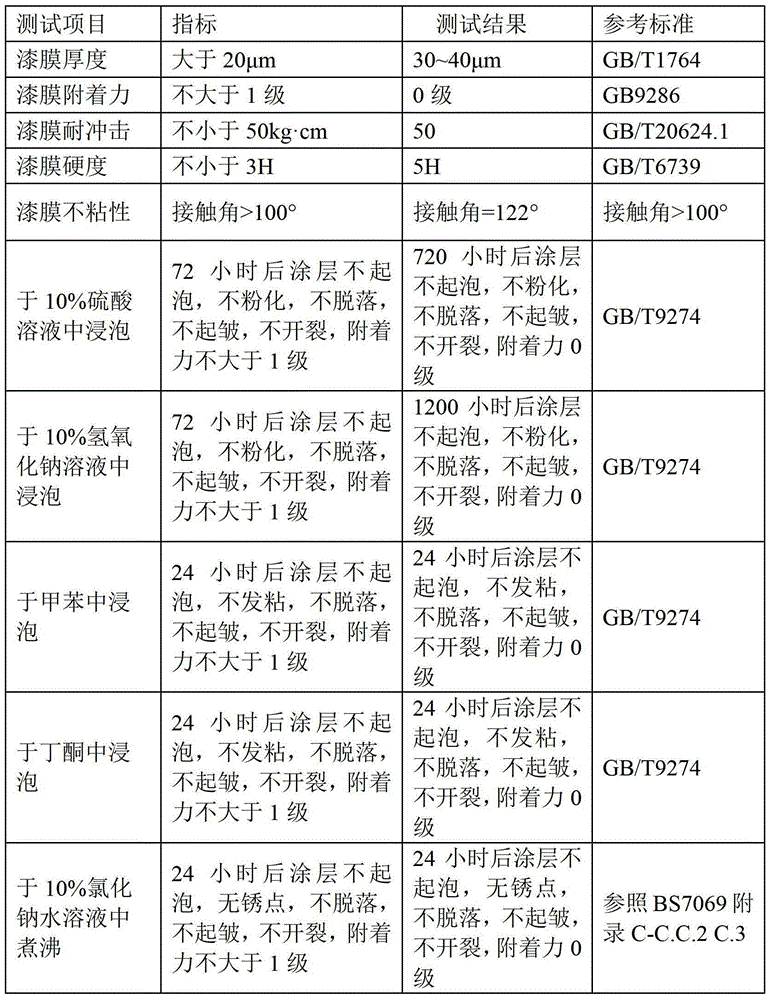

[0034] The coating properties are as follows:

[0035]

Embodiment 3

[0037] 40 grams of thermoplastic polyethersulfone resin with a logarithmic reduced viscosity of 0.37, 30 grams of tetrafluoroethylene-perfluorovinyl ether copolymerized micropowder, 4 grams of fumed silica, 12 grams of titanium dioxide and 18 grams of iron blue pigment, 40 grams gram of barium sulfate, 20 grams of calcium carbonate whiskers, 24 grams of N-methylpyrrolidone, 67 grams of N,N dimethylformamide, 6 grams of cyclohexanone, 15 grams of butanone, 2 grams of toluene, 42 grams of trimethylbenzene and 4 grams of silicone leveling agent was mixed, stirred at a linear speed of 15 m / s for 30 minutes, and then sanded for 6 hours to obtain a thermoplastic high-temperature-resistant anti-sticking anti-corrosion coating for the inner wall of a metal pipe.

[0038] The inner wall of the metal pipe is coated on the inner wall of the metal pipe with a thermoplastic high temperature resistant anti-stick anti-corrosion paint by air spraying.

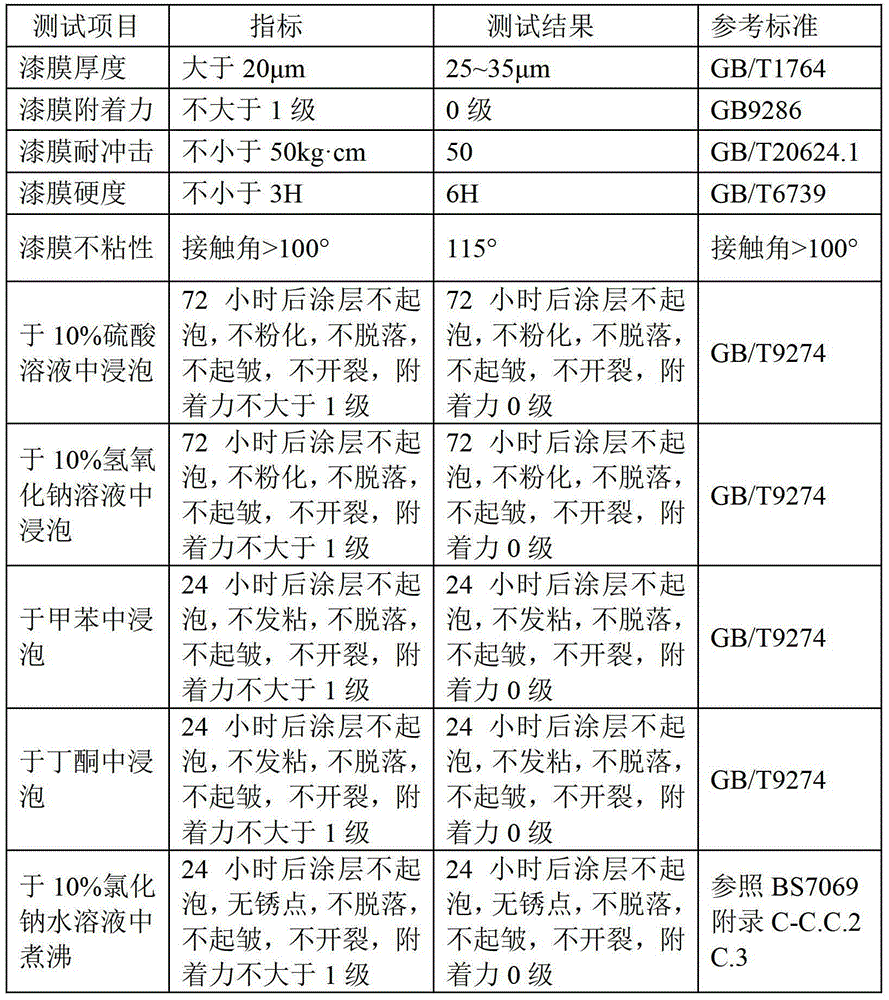

[0039] The coating properties are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com