Composite type hydrate inhibitor

A technology of hydrate inhibitors and compositions, which is applied in the direction of drilling compositions, pipeline systems, chemical instruments and methods, etc., can solve the problems of insufficient inhibition ability and inability to be applied on a large scale, so that it is not easy to block pipelines and reduce costs. Low, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The synthetic method of embodiment 1 polyvinylcaprolactam

[0026] Using N-vinyl caprolactam monomer and azobisisobutyronitrile as an initiator, carry out free radical solution polymerization in an aqueous solution to obtain the polyvinyl caprolactam; the mass ratio of the monomer to the solvent is 1: 2~1:10, the amount of initiator accounts for 5-10% of the mass of the monomer, the reaction temperature of the polymerization reaction is 40-90°C, and the reaction time is 2-12h.

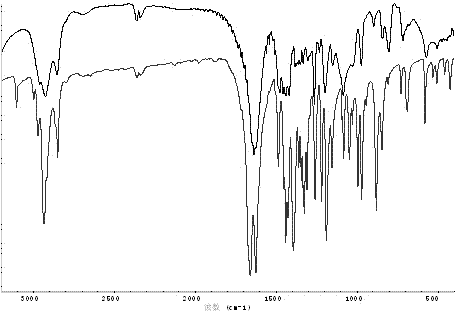

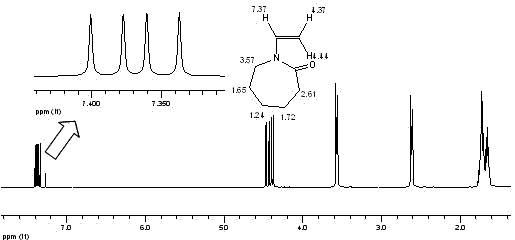

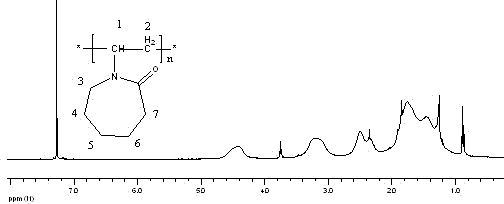

[0027] like figure 1 As shown, comparing the infrared spectra of monomers and polymers, at 1625cm of the polymer infrared spectrum -1 The -C=C bond stretching vibration peak disappears, 3105cm -1处烯碳上 The characteristic absorption of protons also disappeared, so it can be preliminarily determined that the polymer no longer contains double bonds, and the reaction product is polyvinyl caprolactam. like figure 2 and 3 As shown, the monomer N-vinylcaprolactam has a neat single peak, while poly...

Embodiment 2

[0028] Example 2 Experimental method for performance evaluation of inhibitors

[0029] The polyvinyl caprolactam composite inhibitor performance evaluation of the present invention adopts THF test method, specifically:

[0030] (1) Preparation of polyethylene caprolactam inhibition solution

[0031] Accurately weigh a certain mass of polyvinyl caprolactam into a 100ml round bottom flask, add water and stir to dissolve, and prepare polyethylene caprolactam aqueous solutions with mass fractions of 1%, 3%, and 5% for later use.

[0032] (2) Accurately pipette 10 ml of polyethylene caprolactam aqueous solution into a round bottom flask, add 2.65 ml of tetrahydrofuran, stopper the bottle tightly, and shake the flask to mix the inhibitor solution and THF evenly.

[0033] (3) In order to eliminate the influence of room temperature, adjust the temperature of the refrigerator in advance, put the flask in the refrigerator, and keep it at 8°C for 15 minutes to keep the initial state as ...

Embodiment 3

[0041] Based on the quality of water in the system, a compound hydrate inhibitor containing 1% polyvinylcaprolactam mass concentration and 5% methanol mass concentration was prepared, added to 19wt% THF aqueous solution, and the performance was evaluated by THF method. Under normal pressure, the reaction temperature was maintained at 0°C, and the stirring speed was kept consistent in each experiment. Hydrate was formed after 887 minutes of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com