Gold micron feather cluster modified with silver nanoparticles and preparation method and application thereof

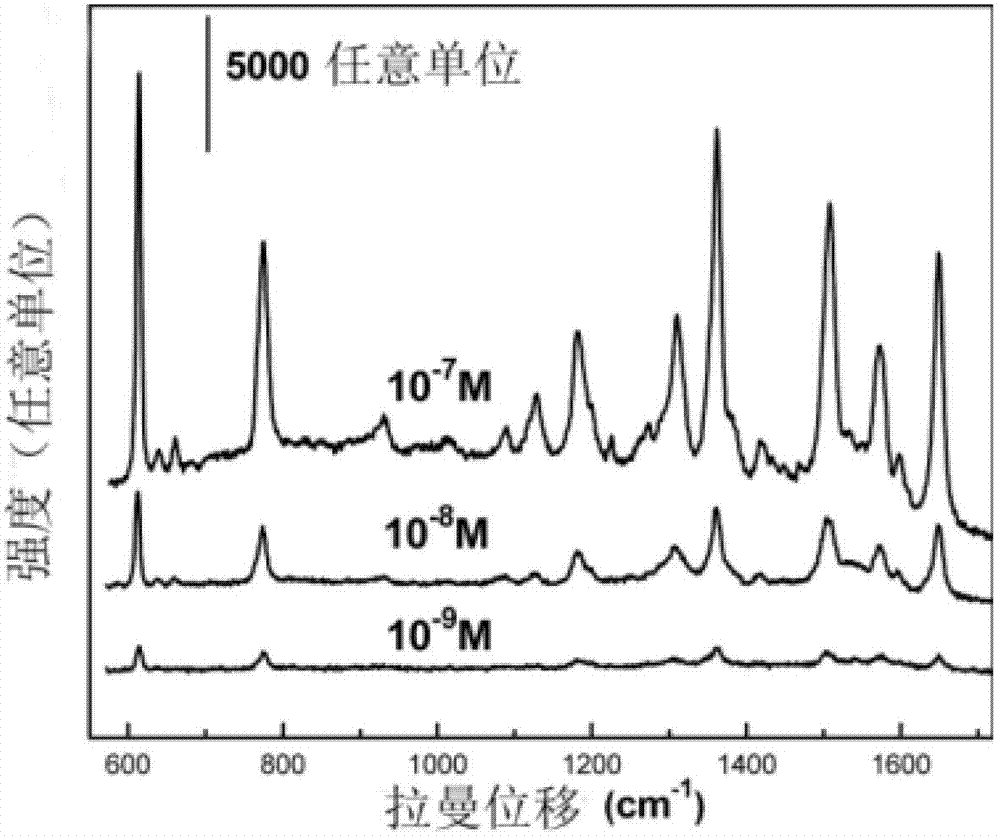

A technology of silver nanoparticles and gold nanoparticles, which is applied in the field of silver nanoparticle-modified gold micro-plume clusters and its preparation, can solve the problem of hindering the enhancement of Raman scattering signals, the weakening of Raman signals, and the reduction of incident light utilization efficiency, etc. problem, to achieve the effect of improving the overall SERS activity, increasing the electromagnetic field enhancement, and facilitating effective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

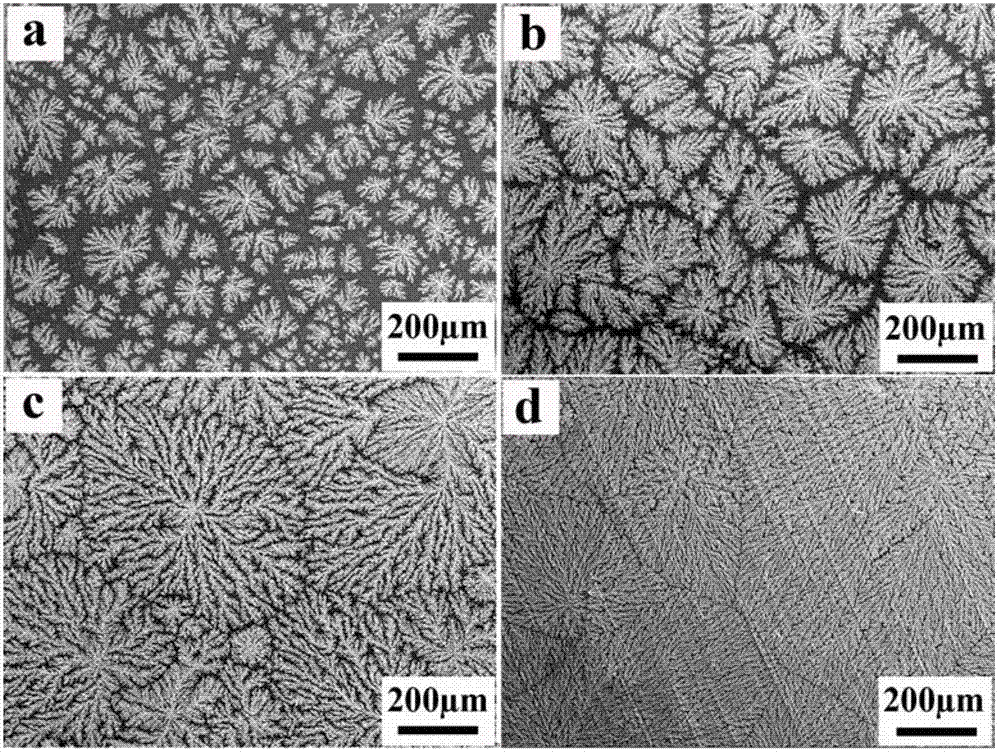

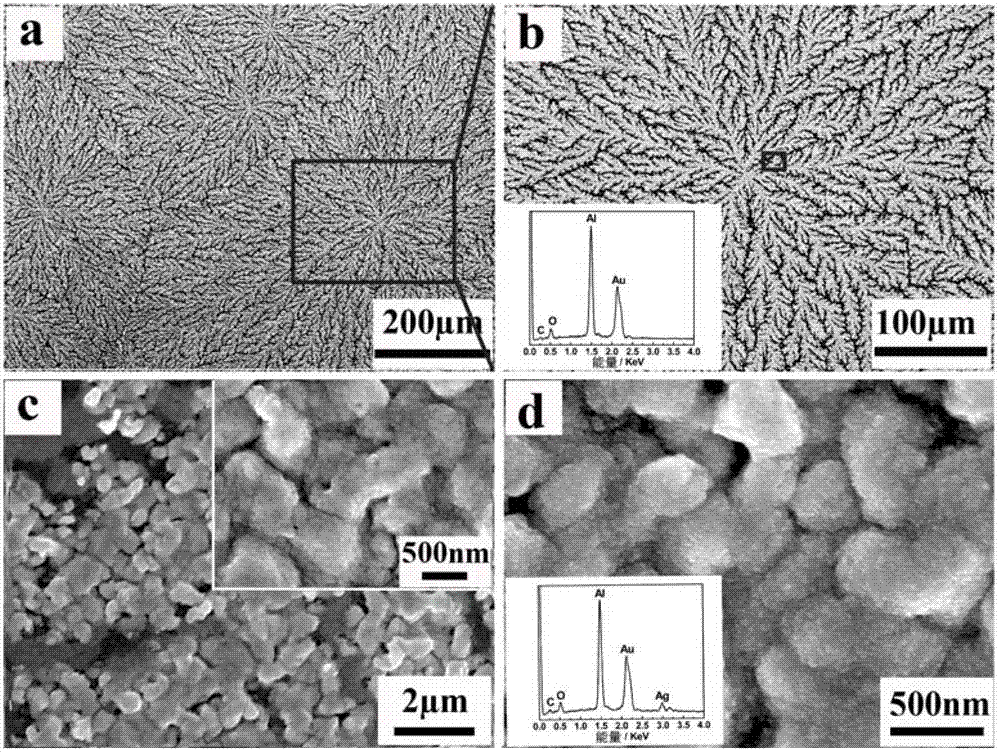

[0030] The concrete steps of preparation are:

[0031] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 6°C and a concentration of 0.2mol / L, anodize it at a DC voltage of 35V for 7 hours, and then place it in a phosphoric acid solution with a temperature of 55°C and a concentration of 5wt%. and 2wt% chromic acid in the mixed solution of immersion 11h; Obtain the aluminum sheet with the array of hexagonal ordered bowl-shaped pits on the surface, wherein, the pit diameter of the bowl-shaped pits that constitute the array of bowl-shaped pits is 30nm, The pit center distance is 50nm. Then place the aluminum sheet with a hexagonal array of bowl-shaped pits on the surface in a magnetron sputtering apparatus for ion sputtering; during sputtering, the distance between it and the gold target is 2cm, and the sputtering current is 15mA 1. The sputtering time is 4 minutes, and the aluminum sheet covered with gold nanoparticles and with a hexagonal a...

Embodiment 2

[0034] The concrete steps of preparation are:

[0035] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 7°C and a concentration of 0.25mol / L, anodize it at a DC voltage of 38V for 6.5h, then place it at a temperature of 58°C and a concentration of 5.5wt% 10.5h in the mixed solution of phosphoric acid and 1.9wt% chromic acid; Obtain an aluminum sheet with a hexagonal array of bowl-shaped pits arranged in an orderly manner on the surface, wherein the pits of the bowl-shaped pits that constitute the array of bowl-shaped pits The diameter is 48nm, and the pit center distance is 68nm. Then place the aluminum sheet with a hexagonal array of bowl-shaped pits on the surface in a magnetron sputtering apparatus for ion sputtering; during sputtering, the distance between it and the gold target is 2cm, and the sputtering current is 15mA 1. The sputtering time is 6 minutes, and the aluminum sheet covered with the gold nanoparticles and the bowl-shape...

Embodiment 3

[0038] The concrete steps of preparation are:

[0039] Step 1, first place the aluminum sheet in an oxalic acid solution with a temperature of 8°C and a concentration of 0.3mol / L, anodize it at a DC voltage of 40V for 6 hours, and then place it in a phosphoric acid solution with a temperature of 60°C and a concentration of 6wt%. and 1.8wt% chromic acid in the mixed solution soaking 10h; Obtain the aluminum plate with the hexagonal array of bowl-shaped pits arranged in an orderly manner on the surface, wherein the diameter of the bowl-shaped pits forming the bowl-shaped pit array is 65nm , The pit center distance is 85nm. Then place the aluminum sheet with a hexagonal array of bowl-shaped pits on the surface in a magnetron sputtering apparatus for ion sputtering; during sputtering, the distance between it and the gold target is 2cm, and the sputtering current is 15mA 1. The sputtering time is 8 minutes, and the aluminum sheet covered with gold nanoparticles and with a hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com