Preparation method of porous ZnO and ZnO/Ag nanometer free-standing film

A self-supporting, nanotechnology, applied in the field of nanomaterial preparation and performance research, can solve the problems of ZnO self-supporting film less, complex preparation methods, etc., to achieve good application prospects, simple equipment, simple container effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

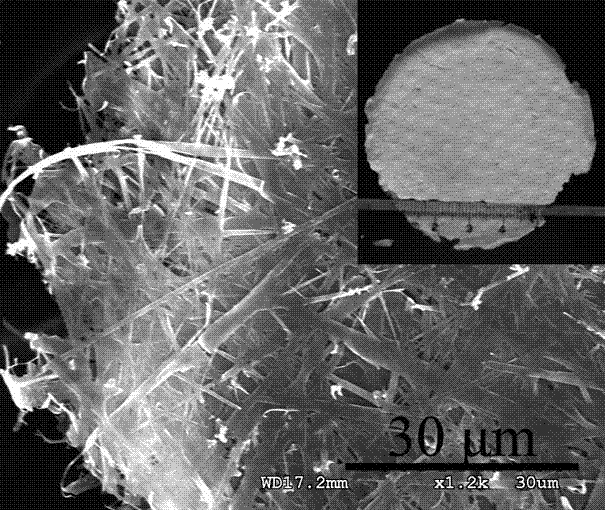

Embodiment 1

[0036] (1) Measure 100 mL of deionized water into a conical flask with a volume greater than 100 mL, add 2.9 g of zinc acetate dihydrate, and dissolve it completely under magnetic stirring.

[0037] (2) Add 1.66 g of hexamethylenetetramine to the above solution and dissolve it completely under stirring.

[0038] (3) After sealing the container, place it in an oven at 60°C for 12 hours.

[0039] (4) Spread the filter paper on the bottom of the suction filter funnel and connect it to the vacuum pump. After preliminarily wetting the filter paper with deionized water, start the vacuum pump and slowly pour the flocculent suspension obtained in step (3) into the funnel for suction filtration Until no more water droplets are filtered out.

[0040] (5) The prepared basic zinc carbonate film together with the filter paper is placed under ambient conditions to dry naturally, and the filter paper is peeled off to obtain a basic zinc carbonate self-supporting film.

[0041] (6) Put the ...

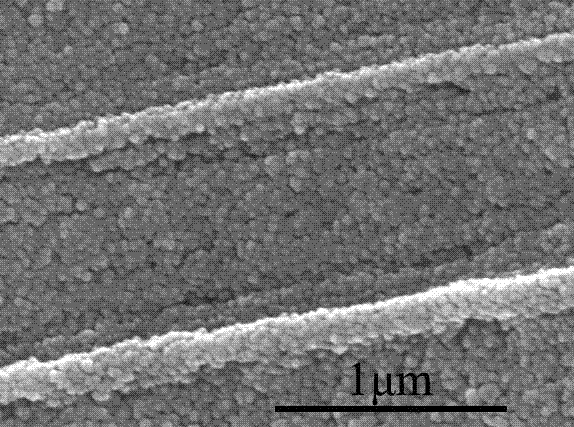

Embodiment 2

[0045] (1) Measure 100 mL of deionized water into a conical flask with a volume greater than 100 mL, add 2.9 g of zinc acetate dihydrate, and dissolve it completely under magnetic stirring.

[0046] (2) Add 2 mL of 0.1 mol·L -1 of silver nitrate solution.

[0047] (3) Add 1.66 g of hexamethylenetetramine to the above solution and dissolve it completely under stirring;

[0048] (4) After sealing the container, place it in an oven and react at 60°C for 12 hours.

[0049] (5) Spread the filter paper on the bottom of the suction filter funnel and connect it to the vacuum pump, and preliminarily wet the filter paper with deionized water, then start the vacuum pump and slowly pour the flocculent suspension obtained in step (3) into the funnel for suction filtration Until no more water droplets are filtered out.

[0050] (6) The prepared basic zinc carbonate nanobelts and silver nanoparticle film together with the filter paper were placed in ambient conditions to dry naturally, an...

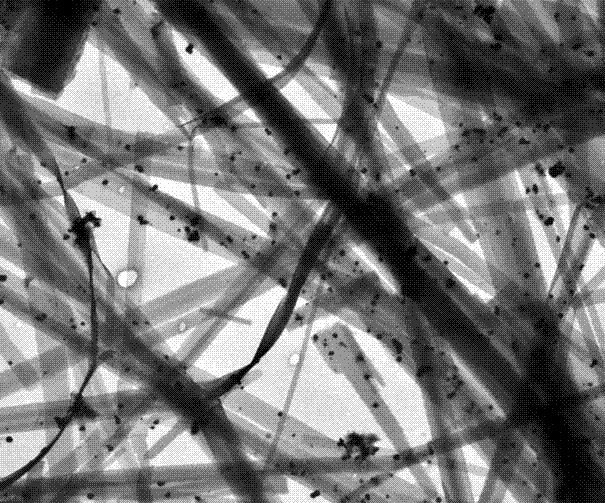

Embodiment 3

[0055] (1) Measure 100 mL of deionized water into a conical flask with a volume greater than 100 mL, add 5.48 g of zinc acetate dihydrate, and dissolve it completely under magnetic stirring.

[0056] (2) Add 3.41 g of hexamethylenetetramine to the above solution and dissolve it completely under stirring.

[0057] (3) After sealing the container, place it in an oven at 50°C for 12 hours.

[0058] (4) Spread the filter paper on the bottom of the suction filter funnel and connect it to the vacuum pump, and preliminarily wet the filter paper with deionized water, then start the vacuum pump and slowly pour the flocculent suspension obtained in step (3) into the funnel for suction filtration Until no more water droplets are filtered out.

[0059] (5) Put the obtained basic zinc carbonate film together with the filter paper to dry naturally at 60°C, and peel off the filter paper to obtain the basic zinc carbonate self-supporting film.

[0060] (6) Put the dried basic zinc carbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com