Cobaltosic oxide quantum dot and preparation method thereof

A technology of cobalt trioxide quantum and cobalt nitrate, which is applied in cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of large particle size of cobalt tetraoxide nanocrystals, complex control of reaction conditions, and unsatisfactory conditions. Quantum confinement conditions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Cobaltous nitrate hexahydrate and ethanol are formulated into clear solution A according to the molar ratio of 1:50;

[0041] 2) Mix 1 ml of solution A with 30-40 ml of undecyl alcohol and add it to the PTFE lining of a 100 ml microwave hydrothermal kettle;

[0042] 3) According to the program: evenly heat up to 180 degrees Celsius within 8 to 10 minutes, keep warm at 180 degrees Celsius for 1 to 3 minutes, and perform microwave hydrothermal reaction. After cooling down, the reaction product was centrifuged at 10,000 rpm for 35 minutes, and the separated product was ultrasonically washed 3 times with ethanol, and then dried in a vacuum oven at 160 degrees Celsius for 8 hours.

Embodiment 2

[0044] 1) Cobaltous nitrate hexahydrate and propanol are formulated into clear solution A according to the molar ratio of 1:40;

[0045] 2) Mix 1 ml of solution A with 30-40 ml of dodecanol and add it to the PTFE lining of a 100 ml microwave hydrothermal kettle;

[0046] 3) According to the program: evenly heat up to 200 degrees Celsius within 8 to 10 minutes, keep warm at 200 degrees Celsius for 1 to 3 minutes, and perform microwave hydrothermal reaction. After cooling down, the reaction product was centrifuged at 10,000 rpm for 35 minutes, and the separated product was ultrasonically washed 3 times with ethanol, and then dried in a vacuum oven at 160 degrees Celsius for 8 hours.

Embodiment 3

[0048] 1) Cobaltous nitrate hexahydrate and n-butanol are formulated into clear solution A according to the molar ratio of 1:60;

[0049] 2) Mix 1 ml of solution A with 30-40 ml of tridecanol and add it to the PTFE lining of a 100 ml microwave hydrothermal kettle;

[0050] 3) According to the program: evenly heat up to 165 degrees Celsius within 8 to 10 minutes, keep warm at 165 degrees Celsius for 1 to 3 minutes, and perform microwave hydrothermal reaction. After cooling down, the reaction product was centrifuged at 10,000 rpm for 35 minutes, and the separated product was ultrasonically washed 3 times with ethanol, and then dried in a vacuum oven at 160 degrees Celsius for 8 hours.

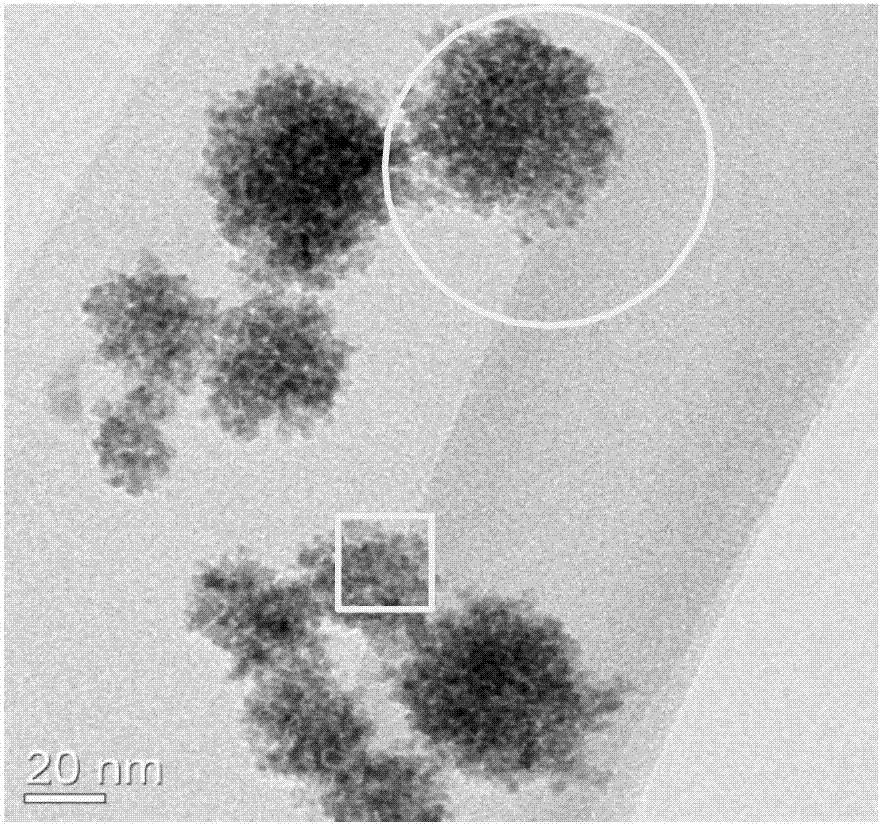

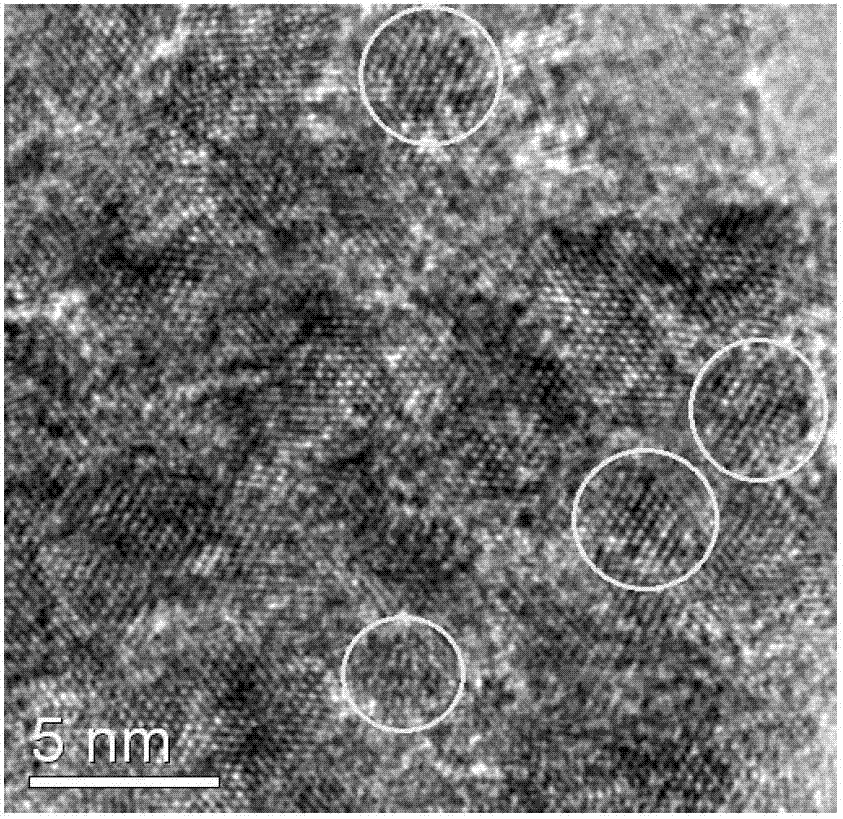

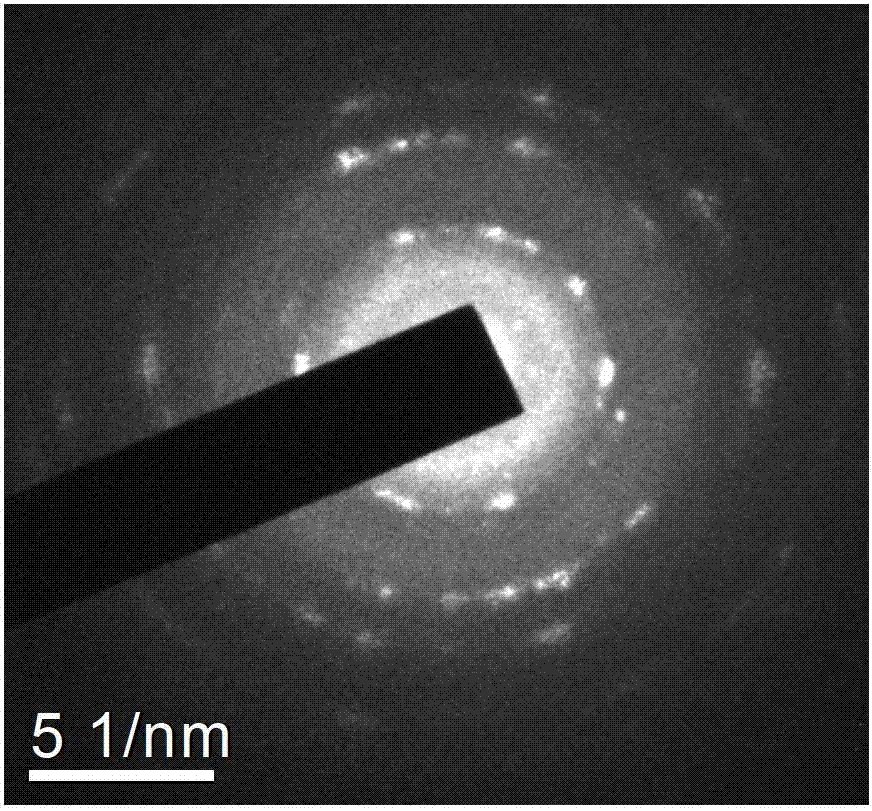

[0051] The cobalt tetroxide quantum dot prepared by the method of the invention has a particle size of 3-4 nanometers and has obvious quantum confinement effect. Due to the small particle size of the synthesized cobalt tetroxide, it can be uniformly dispersed in water to form a brownish-yellow s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com