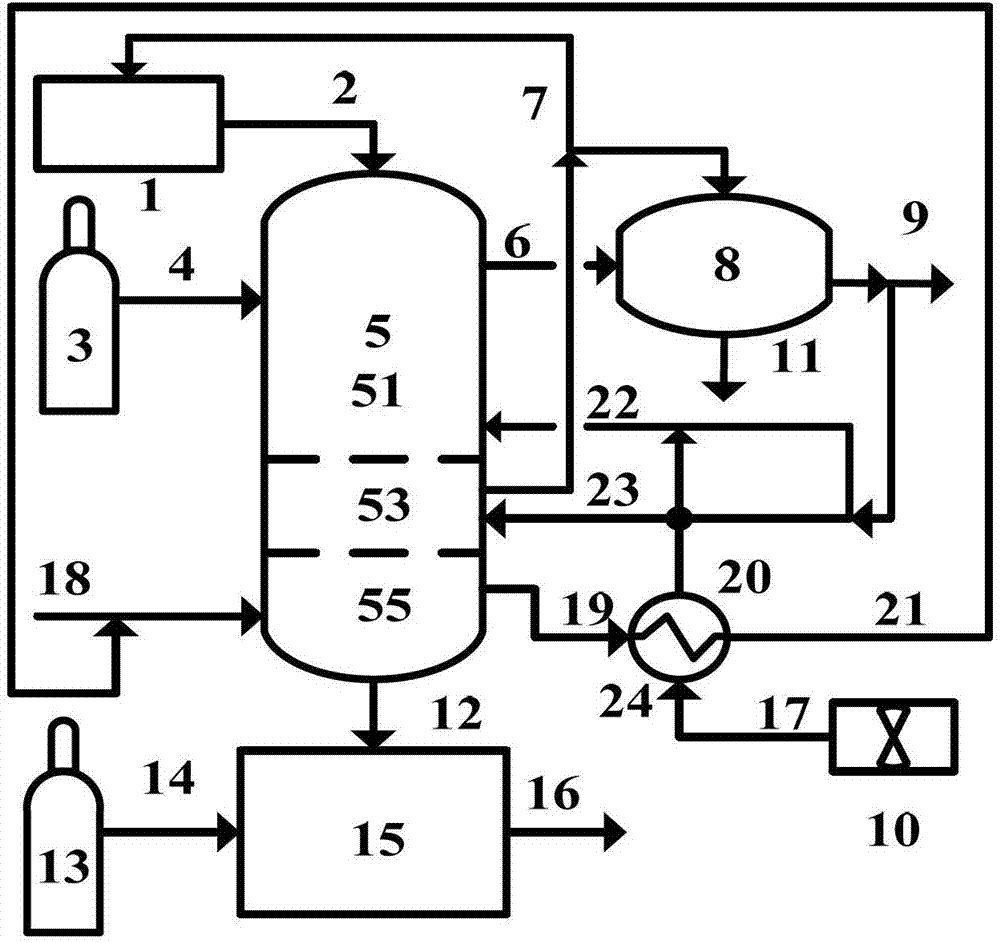

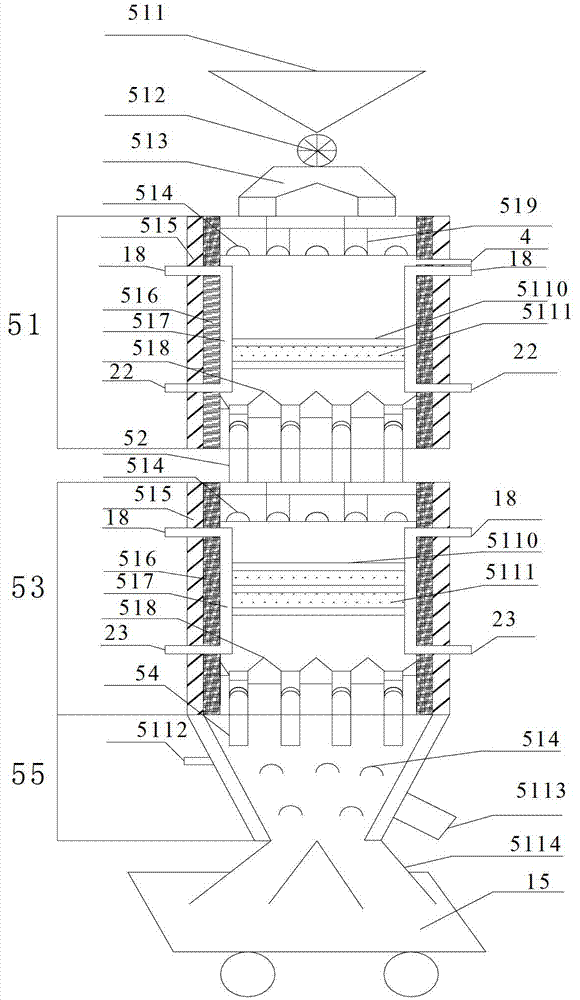

Medium and low temperature distillation furnace of coal, distillation device based on distillation furnace, and distillation method

A dry distillation furnace and low temperature technology, which is used in dry distillation devices and dry distillation fields, can solve the problems of high tar asphaltene content, low calorific value of dry distillation gas, high water content of semi-coke, and achieve high tar yield and light component content. The effect of many, high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In the above-mentioned low-temperature dry distillation method for coal, raw coal with a particle size of 6-80 mm is used as the dry distillation raw material.

[0045] Operating conditions: the temperature of the drying section is 200-250°C, the temperature of the first dry distillation section is 550-600°C, and the temperature of the second dry distillation section is 700-750°C. Purified gas composition (volume fraction) after condensing recovery purification system: H 2 :46-48%, CO: 10-13%, CO 2 : 10-12%, CH 4 : 20-23%, low calorific value: 4100Kcal / Nm 3 , The yield of tar is 16.8%, and the yield of semi-coke is 55%.

Embodiment 2

[0047] In the above-mentioned low-temperature carbonization method for coal, raw coal with a particle size of 6-80mm is used, and a certain amount of waste plastic is added as the raw material for carbonization.

[0048] Operating conditions: the temperature of the drying section is 200-250°C, the temperature of the first dry distillation section is 550-600°C, and the temperature of the second dry distillation section is 700-750°C. Purified gas composition (volume fraction) after condensing recovery purification system: H 2 :48-50%, CO: 9-11%, CO 2 : 9-13%, CH 4 : 23-24%, average low calorific value: 4500Kcal / Nm 3 . The tar yield is 18.2%, and the semi-coke yield is 58%.

Embodiment 3

[0050] In the above-mentioned medium-low temperature dry distillation method for coal, raw coal with a particle size of 6-80 mm is used, and a certain amount of biomass is added as the dry distillation raw material.

[0051] Operating conditions: the temperature of the drying section is 200-250°C, the temperature of the first dry distillation section is 550-600°C, and the temperature of the second dry distillation section is 700-750°C. Purified gas composition (volume fraction) after condensing recovery purification system: H 2 :47-49%, CO:8-12%, CO 2 : 12-13%, CH 4 : 24-25%, average low calorific value: 4400Kcal / Nm 3 . The tar yield is 18.7%, and the semi-coke yield is 56%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com