Lead-free antimony-nickel-brass alloy

A technology of nickel brass and alloy, applied in the field of lead-free antimony-nickel brass alloy, which can solve the problems that the lead content of copper alloy cannot be reduced, cracks are easy to occur, and the machinability is poor, so as to achieve good toughness and processability, and improve cutting properties, and the effect of improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0054] The measured values of the lead-free antimony-nickel brass in Example 3 are Cu: 62.13wt%; Bi: 0.0061wt%; Al: 0.114wt%; Pb: 0.005wt%; Mg: 0.274wt%; Zr: 0.263wt% %; Ni: 0.912wt%; Sn: 0.438wt%; Sb: 0.134wt%.

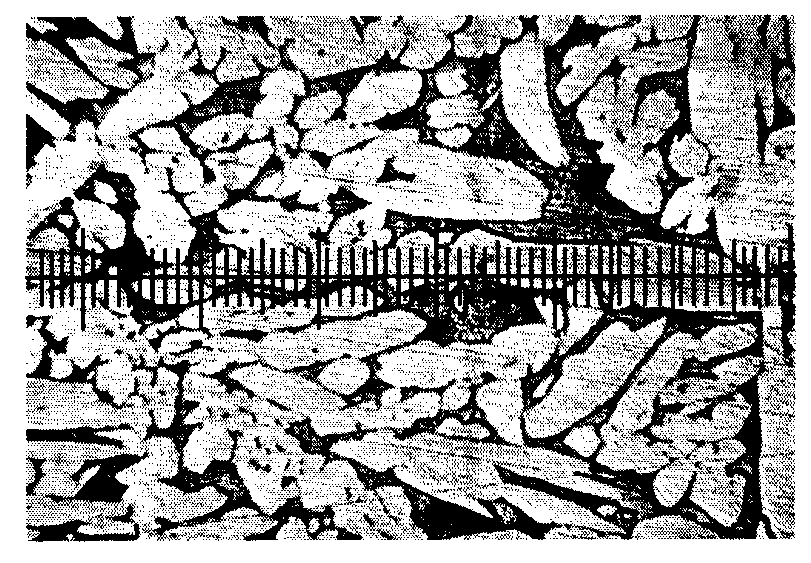

[0055] Figure 1A It shows the weave distribution of the lead-free antimony-nickel brass in Example 3, which has a rounded crystal phase structure, and some grains are fine and round, which can make the material easier to break chips and provide good machinability; and the α phase ratio is high , so the ductility will be improved, and the material has low brittle crack sensitivity and is not easy to break, so it is not easy to produce defects such as cracks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com