Vertical airflow type MOCVD (Metal-organic Chemical Vapor Deposition) spray head device with multiple gas mixing chambers

A technology of vertical airflow and gas mixing chamber, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., to improve the migration rate and eliminate the effect of pre-reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

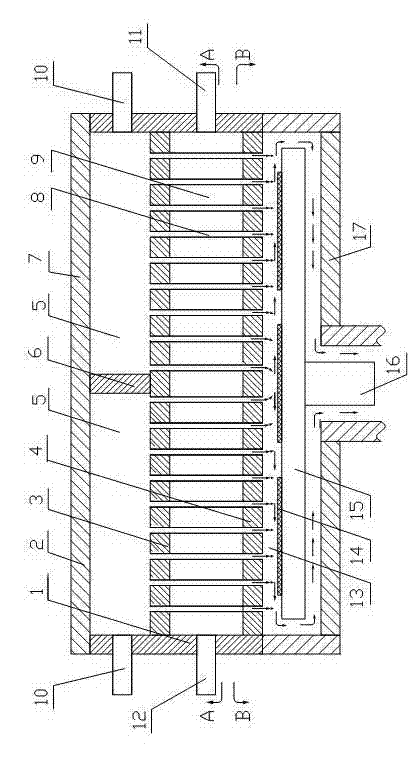

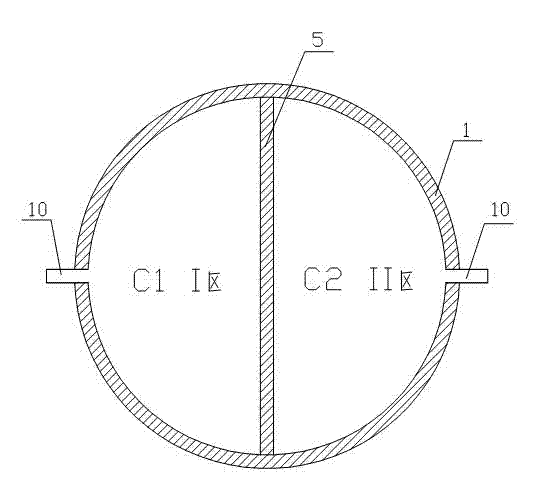

[0034] Example 1: Two mixing chambers

[0035] A multi-chamber vertical airflow MOCVD nozzle device, comprising: a cylindrical closed shell 7 formed by a top plate 2, a side wall 1 and a bottom plate 4, and the closed shell 7 is connected with the MOCVD reaction chamber 13 below as a whole , the inside of the closed housing 7 is divided into two independent and mutually sealed sealed chambers 5 and water-cooled chambers 9 by the middle plate 3, the sealed chamber 5 is located above the middle plate 3, located below the middle plate 3, and is connected to the MOCVD reaction chamber 13 Adjacent is the water-cooling chamber 9, on the side walls corresponding to the two ends of the water-cooling chamber 9, a cooling water inlet pipe 12 and a cooling water outlet pipe 11 are respectively installed, and the sealed chamber 5 is divided into two independent volumes by a vertical separator 6 The same and fan-shaped gas mixing chambers C1 and C2 are respectively equipped with a gas mixi...

Embodiment 2

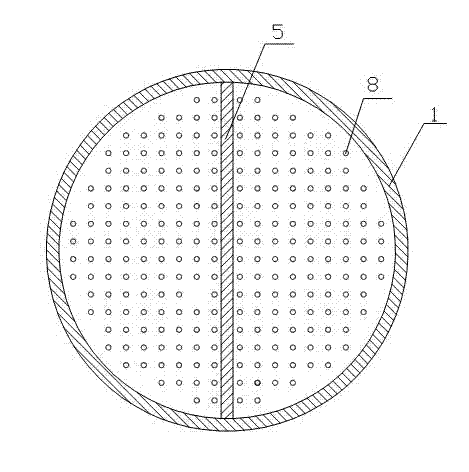

[0040] The structure of embodiment 2 is basically the same as that of embodiment 1, the difference is:

[0041] The isolation body 6 is a hollow isolation cavity type, and an air intake duct 19 is installed on the side wall 1 of the isolation cavity 18 , and air intake pores 8 are distributed on the middle plate 3 connecting with the isolation cavity 18 .

[0042] The carrier gas of the MO source can be fed into the isolation chamber 18 , and the same as the reaction gas in the gas mixing chamber, the carrier gas will enter the MOCVD reaction chamber 13 through the inlet pores 8 . After the carrier gas is passed into the MOCVD reaction chamber 13, the reaction gas injected from the gas mixing chamber I region C1 and the reaction gas injected from the II region C2 will be separated by the carrier gas injected from the isolation 18, thereby slowing down Diffusion between the above reacting gases.

Embodiment 3

[0044] The structure of embodiment 3 is basically the same as that of embodiment 1, the difference is:

[0045] The separator 5 divides the sealed chamber 5 into four zones: C1, C2, C3 and C4.

[0046] When the pre-reaction products of the two types of reaction gases are solid (such as growing P-type GaN) or their pre-reaction is not conducive to material growth (such as growing nitrides with high aluminum components), the adjacent gas mixing chambers are filled with different types of gas. reaction gas, the substrate 14 rotates through the two gas mixing chambers, which means that the substrate 14 has continuously passed through the gas flow regions of the two types of reaction gases; the more the number of gas mixing chambers, the smaller the angle of rotation required, The shorter the required time (the rotation speed of the substrate is constant), the more uniform ion concentration can be obtained above the substrate 14 in a shorter time, which can improve the uniformity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com