Dedusting filter material containing MnO2 catalyst, and preparation method and application thereof

A catalyst and filter material technology, which is applied in the field of dust removal filter material containing MnO2 catalyst and its preparation, can solve the problems of complicated tail flue gas purification system and high treatment cost, and achieves processing cost saving, strong economic practicability, and site space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

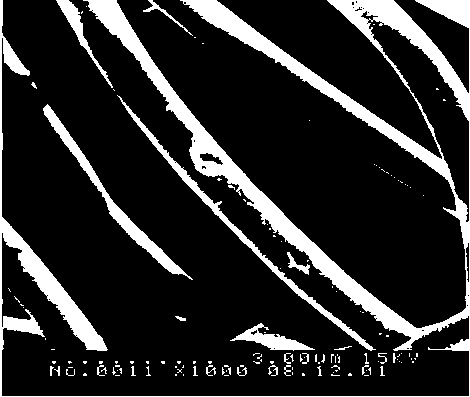

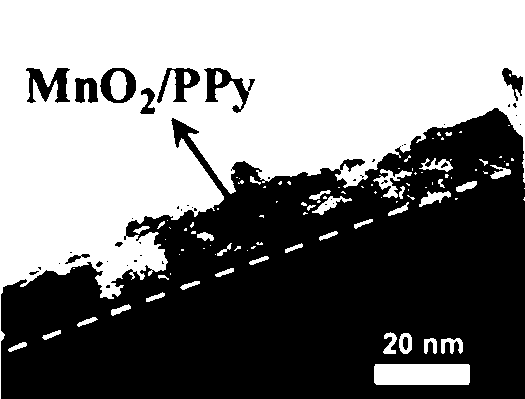

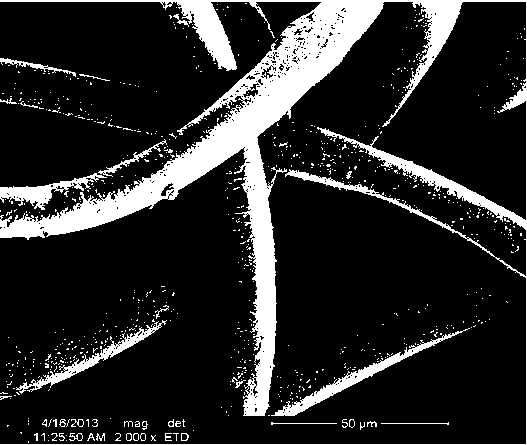

[0028] First, weigh 0.8g of the purified pyrrole monomer and dissolve it in 40mL of acetone to make a 0.3mol / L pyrrole acetone solution, then immerse a circular PPS filter material with a diameter of 3.8cm in the above solution and wait for adsorption for 12 hours Afterwards, the PPS filter material was taken out and dried at room temperature for 1 h. Then add the filter material into 40 mL acidic potassium permanganate solution for ultrasonic reaction for 1 hour, the concentration of potassium permanganate is 0.05 mol / L, and the concentration of sulfuric acid is 1 mol / L. Finally, take out the filter material, wash the residual liquid on it with water and ethanol, put it in an oven and dry it for 6 hours at 110°C for testing. The filter media loading is about 3.5 mg / cm 2 .

[0029] The denitrification performance of the composite filter material was evaluated in a self-made tubular SCR reactor. NO and NH 3 Volume fraction is 0.05%, O 2 The volume fraction is 5%, the rest ...

Embodiment 2

[0031] First, weigh 0.8g of the purified pyrrole monomer and dissolve it in 40mL of acetone to make a 0.3mol / L pyrrole acetone solution, then immerse a circular PPS filter material with a diameter of 3.8cm in the above solution and wait for adsorption for 12 hours Afterwards, the PPS filter material was taken out and dried at room temperature for 0.5 h. Then add the filter material into 40mL acidic potassium permanganate solution for immersion reaction for 12 hours, the concentration of potassium permanganate is 0.025mol / L, and the concentration of sulfuric acid is 1mol / L. Finally, take out the filter material, wash the residual liquid on it with water and ethanol, put it in an oven and dry it for 6 hours at 110°C for testing. The filter media loading is about 2.2 mg / cm 2 .

[0032] The denitrification performance of the composite filter material was evaluated in a self-made tubular SCR reactor. NO and NH 3 Volume fraction is 0.05%, O 2 The volume fraction is 5%, the rest...

Embodiment 3

[0034] First, weigh 1.3g of purified pyrrole monomer and dissolve it in 40mL of acetone to make a 0.5mol / L pyrrole acetone solution, then immerse a circular PPS filter material with a diameter of 3.8cm in the above solution and wait for adsorption for 6h Afterwards, the PPS filter material was taken out and dried at room temperature for 2 h. Then add the filter material into 40 mL of acidic potassium permanganate solution for ultrasonic reaction for 0.5 h, the concentration of potassium permanganate is 0.1 mol / L, and the concentration of sulfuric acid is 1 mol / L. Finally, take out the filter material, wash the residual liquid on it with water and ethanol, put it in an oven and dry it for 3 hours at 110°C for testing. The filter media loading is about 10 mg / cm 2 .

[0035] The denitrification performance of the composite filter material was evaluated in a self-made tubular SCR reactor. NO and NH 3 Volume fraction is 0.05%, O 2 The volume fraction is 5%, the rest is N 2 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com