TiO2-loaded packing and preparation method thereof

A polyurethane sponge and solution technology, applied in the field of water treatment, can solve the problems of difficulty in achieving downstream biodegradation goals, insufficient biodegradability, and increased processing costs, and achieve the effects of abundant raw materials, low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

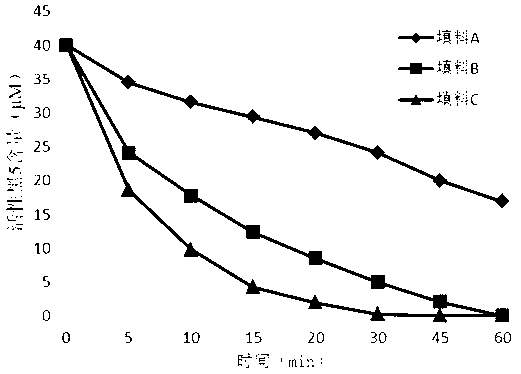

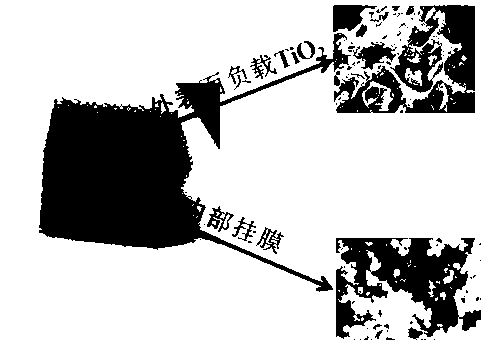

[0024] A loaded TiO 2 The filler, which includes polyurethane sponge block and TiO 2 ,TiO 2 All loads are on the polyurethane sponge block, wherein the polyurethane sponge block has a side length of 4.0mm and a specific surface area of 4.8m 2 / g, the porosity is 88%, and the density after immersion is 1.01g / cm 3 .

[0025] The above loaded TiO 2 Filling preparation method:

[0026] Add 23.9 g titanium isopropoxide to 150 mL HNO 3 (0.5mol / L) solution, heated in a water bath at 80°C until the volume of the solution was concentrated to 50mL, and after cooling to room temperature, added an appropriate amount of trimesic acid with a mass percentage of 5% (trimesic acid is a commonly used binder) ; Cover the beaker containing the solution with aluminum foil, and obtain a suspension solution after 18 hours in an oil bath at 130°C, and cool to room temperature; put 10g of polyurethane sponge block into the suspension solution, place it in an oven at 80°C for 5h, and use it eve...

Embodiment 2

[0028] A loaded TiO 2 The filler, which includes polyurethane sponge block and TiO 2 , the TiO 2 Loaded on the polyurethane sponge block, wherein the polyurethane sponge block has a side length of 4.0mm and a specific surface area of 4.8m 2 / g, the porosity is 92%, and the density after immersion is 1.01g / cm 3 .

[0029] The above loaded TiO 2 Filling preparation method:

[0030] Add 23.9 g titanium isopropoxide to 150 mL HNO 3 (0.5mol / L) solution, heated in a water bath at 75°C until the volume of the solution was concentrated to 67mL, and after cooling to room temperature, added an appropriate amount of trimesic acid with a mass percentage of 5% (trimesic acid is a commonly used binder) ; Cover the beaker containing the solution with aluminum foil, and obtain a suspension solution after an oil bath at 110°C for 15 hours, and cool to room temperature; put 10g of polyurethane sponge block into the suspension solution, place it in an oven at 70°C for 5h, and use it ever...

Embodiment 3

[0032] A loaded TiO 2 The filler, which includes polyurethane sponge block and TiO 2 , the TiO 2 Loaded on the polyurethane sponge block, wherein the polyurethane sponge block has a side length of 4.0mm and a specific surface area of 4.8m 2 / g, the porosity is 95%, and the density after immersion is 1.02g / cm 3 .

[0033] The above loaded TiO 2 Filling preparation method:

[0034] Add 23.9 g titanium isopropoxide to 150 mL HNO 3 (0.5mol / L) solution, heated in a water bath at 85°C until the volume of the solution was concentrated to 75mL, and after cooling to room temperature, added an appropriate amount of trimesic acid with a mass percentage of 5% (trimesic acid is a commonly used binder) ; Cover the beaker containing the solution with aluminum foil, and obtain a suspension solution after 20 hours in an oil bath at 120 ° C, and cool to room temperature; put 10 g of polyurethane sponge into the suspension solution, place it in a 75 ° C oven for 5 hours, and use it every...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com