Poly(methylsilane-carbosilane) and preparation method thereof

A technology of methylsilane and carbosilane, which is applied in the field of polysilane and its preparation, can solve problems such as introduction obstacles, achieve the effects of improved safety, improved curing molding process, and high ceramic yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

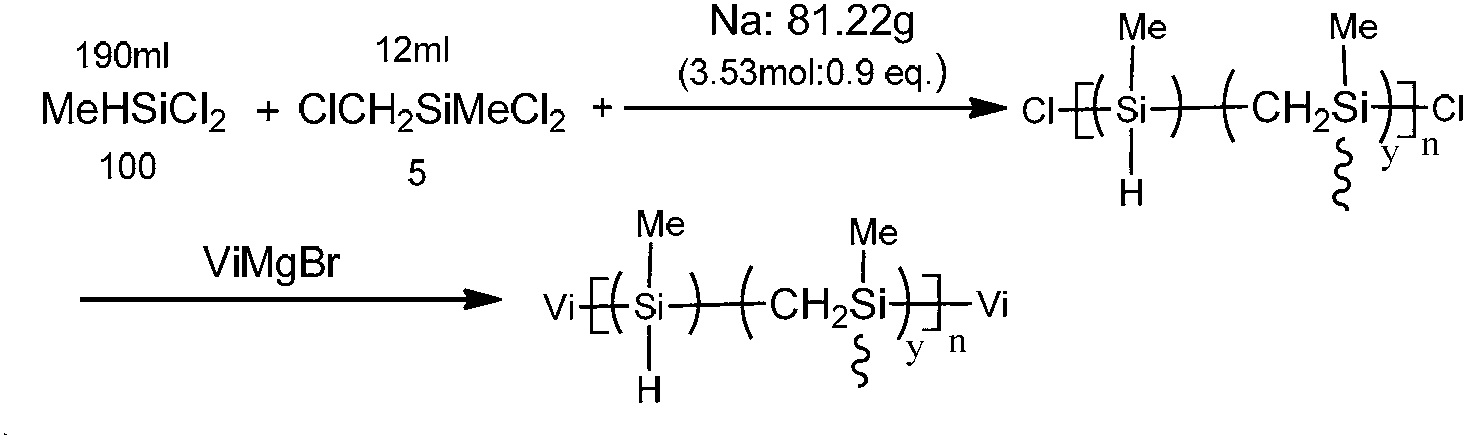

Method used

Image

Examples

Embodiment 1

[0033] Install a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, and a gas guiding device on a dry 3L three-neck round bottom flask, and then vacuumize and replace with nitrogen three times. Under the protection of nitrogen, add 750ml of newly distilled xylene, 50ml of dioxane and 3.53mol (0.9 times of Si-Cl equivalent) Na cut into small pieces into the three-necked flask, and add formazan to the constant pressure dropping funnel. Dichlorosilane (1.825mol)-chloromethylmethyldichlorosilane (0.09175mol) monomer mixture. After the device is heated up to Na melting, adjust and stir to prepare sodium sand, add the monomer mixture dropwise (3-4 hours), after the dropwise addition is completed, continue to react at 115°C for 4 hours, stop stirring, cool naturally, and then transfer and filter to obtain Si-Cl polymer solution, distill off the solvent and add 500ml tetrahydrofuran for the next step of Grignard coupling reaction.

[0034] During the Grignar...

Embodiment 2

[0037] Install a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, and a gas guiding device on a dry 3L three-necked round bottom flask, and then vacuumize and replace nitrogen three times. Under nitrogen protection, add 750ml of freshly distilled xylene, 50ml of tetrahydrofuran and 4.0mol of Na cut into small pieces into a three-necked flask, and add methyldichlorosilane (1.825mol)-chloromethyl A mixture of methyldichlorosilane (0.1825mol) and freshly distilled xylene. After the device is heated up to Na melting, start stirring to prepare sodium sand, add monomer solution dropwise, and then react at 110-120°C for 5 hours to obtain an intermediate polymer containing Si-Cl bonds. After adding 200ml of dry tetrahydrofuran, add 440mL of 1.0mol / L ViMgBr tetrahydrofuran solution dropwise into the above reaction system, react at 60°C for 6 hours, stop stirring, and cool naturally. Then mix the hydrochloric acid-ice-water mixture of excess 100ml, 3mol / L hy...

Embodiment 3

[0039] Install a mechanical stirrer, a constant pressure dropping funnel, a reflux condenser, and a gas guiding device on a dry 2L three-necked round-bottomed flask, and then vacuumize and replace nitrogen three times, then add 300ml of newly distilled xylene-di Hexane mixed solution and 35.32g (1.53mol) of Na cut into small pieces, add methyldichlorosilane (0.73mol)-chloromethylmethyldichlorosilane (0.0365mol)- A mixture of chloromethyldimethylsilyl chloride (0.073mol) and freshly distilled xylene. Heat up the device, adjust the stirring until the Na melts, prepare sodium sand, add the monomer mixture dropwise, after the dropwise addition, keep the temperature at 100-120°C, react for 8 hours, stop stirring, cool naturally, then transfer and filter, inert Distilled under atmosphere, the resulting concentrated intermediate polymer was used in the Grignard reaction.

[0040] During the Grignard reaction, 1.0 mol / L ViMgBr THF solution (5%-15% excess) was added dropwise to the TH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com