Method for preparing humidity-sensitive film

A moisture-sensitive, thin-film technology, applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of performance impact and large volume, and achieve the effects of controllable thickness, low preparation cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

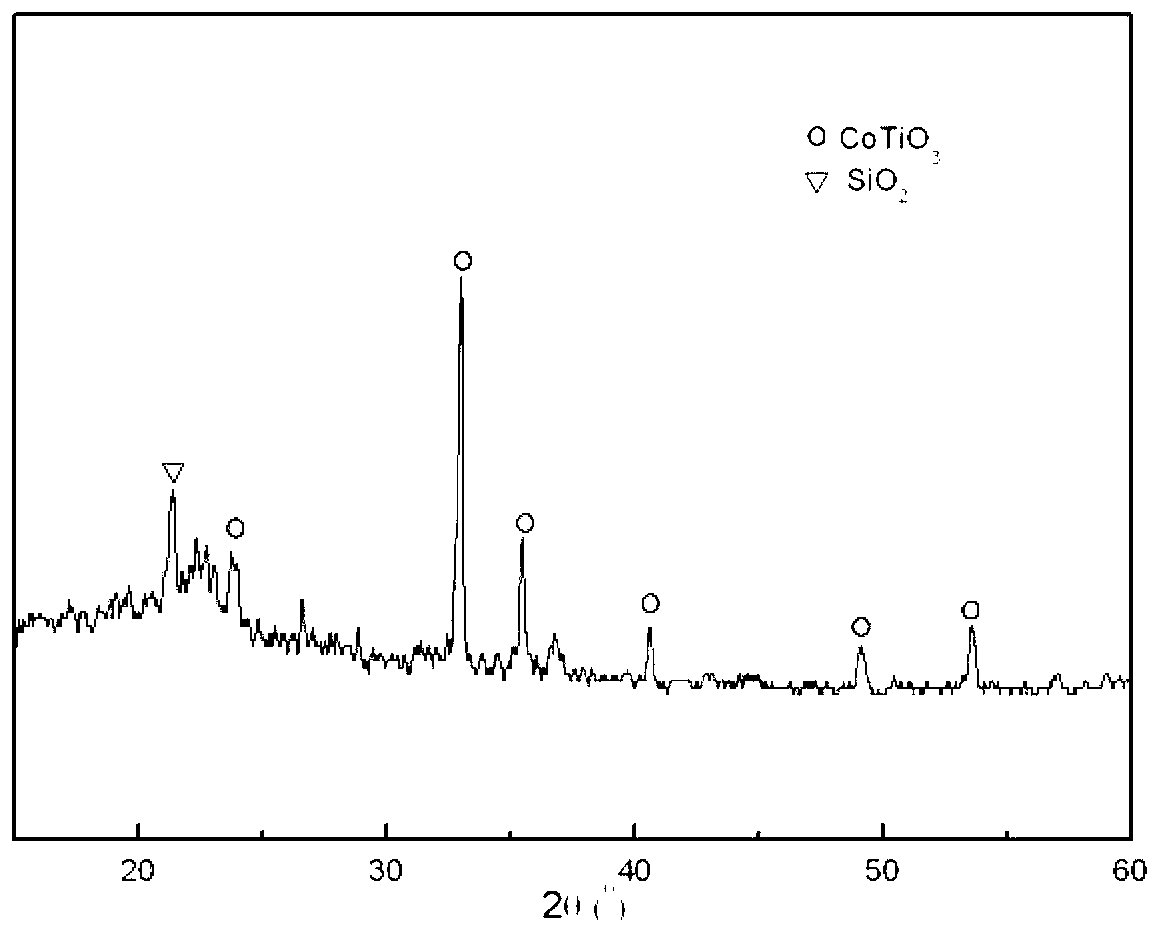

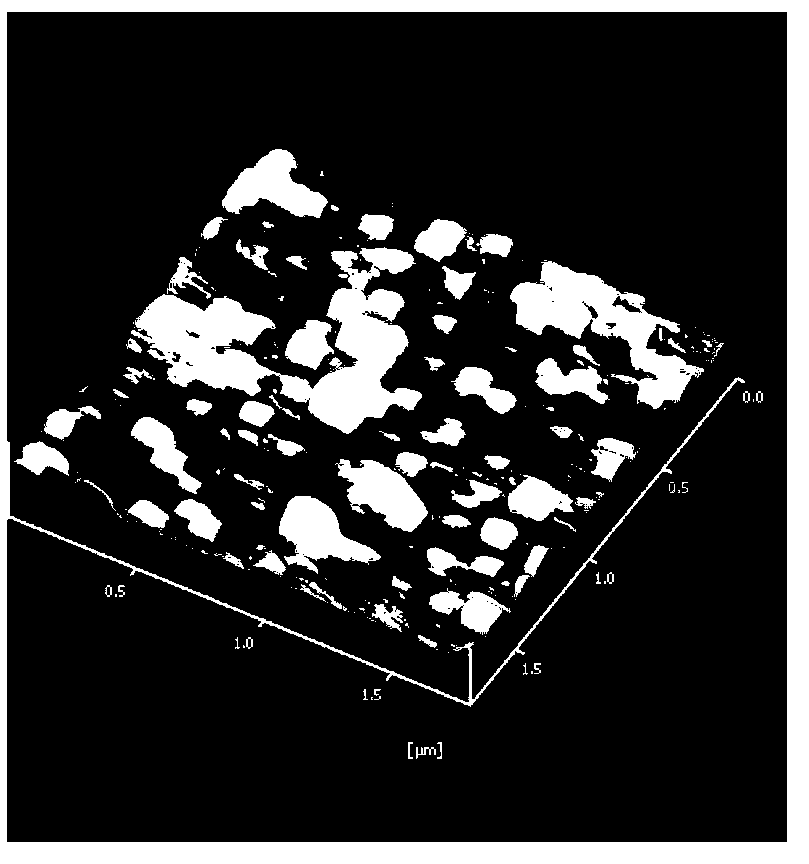

Image

Examples

Embodiment 1

[0021] 1) Take analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and can completely dissolve cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Analytical absolute ethanol (C 2 h 5 OH), analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) dissolved in analytical grade absolute ethanol (C 2 h 5 OH), and then slowly add analytically pure butyl phthalate (Ti(OC 4 h 9 ) 4 ), formulated as Co 2+ : Ti 4+ = 1:0.5 molar ratio of the mixed solution, fully stirred at room temperature to obtain a uniform red transparent solution A;

[0022] 2) Slowly add aqueous citric acid solution dropwise to solution A, adjust the pH value of the solution to 1.0, and obtain purple-red sol B;

[0023] 3) Let Sol B stand at 20°C for 48 hours to obtain Gel C;

[0024] 4) Put the substrate to be coated into the mixed solution of acetone and ethanol with a volume ratio of 1:3 for ultrasonic cleaning, the ultrasonic power is 50W, rinse the cleaned substrate with...

Embodiment 2

[0028] 1) Take analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and can completely dissolve cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Analytical absolute ethanol (C 2 h 5 OH), analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) dissolved in analytical grade absolute ethanol (C 2 h 5 OH), and then slowly add analytically pure butyl phthalate (Ti(OC 4 h 9 ) 4 ), formulated as Co 2+ : Ti 4+ = 1:3 molar ratio mixed solution, fully stirred at room temperature to obtain a uniform red transparent solution A;

[0029] 2) Slowly add aqueous citric acid solution dropwise to solution A, adjust the pH value of the solution to 7.0, and obtain purple-red sol B;

[0030] 3) Let Sol B stand at 60°C for 10 hours to obtain Gel C;

[0031] 4) Put the substrate to be coated into a mixed solution of acetone and ethanol with a volume ratio of 1:8 for ultrasonic cleaning, the ultrasonic power is 50W, rinse the cleaned substrate with deionized ...

Embodiment 3

[0035] 1) Take analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and can completely dissolve cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Analytical absolute ethanol (C 2 h 5 OH), analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) dissolved in analytical grade absolute ethanol (C 2 h 5 OH), and then slowly add analytically pure butyl phthalate (Ti(OC 4 h 9 ) 4 ), formulated as Co 2+ : Ti 4+ = 1:1 molar ratio mixed solution, fully stirred at room temperature to obtain a uniform red transparent solution A;

[0036] 2) Slowly add aqueous citric acid solution dropwise to solution A, adjust the pH value of the solution to 4.0, and obtain purple-red sol B;

[0037] 3) Let Sol B stand at 30°C for 25 hours to obtain Gel C;

[0038] 4) Put the substrate to be coated into a mixed solution of acetone and ethanol with a volume ratio of 1:5 for ultrasonic cleaning, the ultrasonic power is 50W, rinse the cleaned substrate with deionized wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com