A kind of low-temperature electrolyte solution for ternary power lithium-ion battery and preparation method thereof

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low low-temperature discharge efficiency, achieve high low-temperature discharge efficiency, reasonable ratio, and improve low-temperature discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

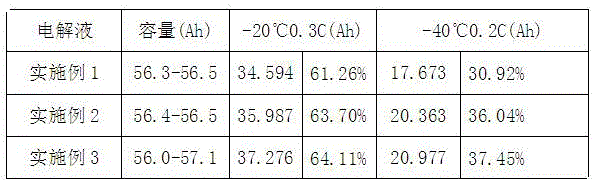

[0022] Example 1: In a nitrogen-filled glove box (moisture content is less than 0.9 ppm), the dehydrated organic solvents ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl carbonate EMC and methyl acetate MA are fully mixed uniformly, The volume ratio of organic solvent ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl carbonate EMC, and methyl acetate MA is 4:9:6:6 (water content is less than 10ppm), and then slowly add LiPF 6 , and magnetically stir until the lithium salt is fully dissolved, finally add vinylene carbonate VC and 1,3-propane sultone PS, continue to stir until all components are evenly mixed, and set aside for 0.5h to obtain Example 1 low-temperature lithium For the ion battery electrolyte, the concentration of the above-mentioned lithium salt in the electrolyte is 1.5mol / L, the organic solvent accounts for 95%, and the additives account for 5%.

Embodiment 2

[0024] In a nitrogen-filled glove box (with moisture less than 0.9 ppm), the dehydrated organic solvents ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl carbonate EMC and methyl acetate MA are thoroughly mixed, and the organic solvent ethylene carbonate The volume ratio of ester EC, dimethyl carbonate DMC, methyl ethyl carbonate EMC, and methyl acetate MA is 4:9:6:8 (water content is less than 10ppm), and then LiPF is slowly added 6 , and stir with a magnetic stirrer until the lithium salt is fully dissolved, and finally add vinylene carbonate VC and 1,3-propane sultone PS, and continue to stir until all components are mixed evenly, set aside for 0.5h to obtain Example 2 Low-temperature lithium-ion battery electrolyte, the concentration of the above-mentioned lithium salt in the electrolyte is 0.8mol / L, the organic solvent accounts for 90%, and the additives account for 10%.

Embodiment 3

[0026] In a nitrogen-filled glove box (with moisture less than 0.9 ppm), the dehydrated organic solvents ethylene carbonate EC, dimethyl carbonate DMC, ethyl methyl carbonate EMC and methyl acetate MA are thoroughly mixed, and the organic solvent ethylene carbonate The volume ratio of ester EC, dimethyl carbonate DMC, methyl ethyl carbonate EMC, and methyl acetate MA is 4:9:6:8 (water content is less than 10ppm), and then slowly add LiPF 6 , and magnetically stir until the lithium salt is fully dissolved, finally add a little each of vinylene carbonate VC, 1,3-propane sultone PS and fluoroethylene carbonate, continue stirring until all components are mixed evenly, set aside for 0.5h, That is, the low-temperature lithium-ion battery electrolyte of Example 3 is obtained, the concentration of the above-mentioned lithium salt in the electrolyte is 0.6 mol / L, the organic solvent accounts for 85%, and the additives account for 15%.

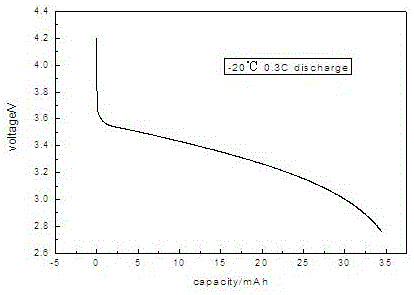

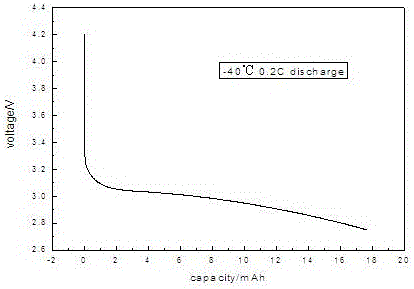

[0027] According to the production standards of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com