Modified ultralow-temperature lithium iron phosphate composite material, positive electrode material and preparation method thereof

A lithium iron phosphate and composite material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as low low-temperature discharge efficiency, improve median voltage, reduce side reactions of dissolution and corrosion, and improve low-temperature discharge. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] An embodiment of the present invention provides a method for preparing a modified ultra-low temperature lithium iron phosphate composite material, including:

[0051] S101, adding a lithium source, an iron source, a phosphorus source, and a first carbon source into the first solvent for mixing to obtain a first mixture;

[0052] Wherein, the lithium source is selected from one or more of lithium carbonate, lithium hydroxide, lithium acetate, lithium citrate, lithium dihydrogen phosphate; the iron source is selected from iron oxide, ferric oxide, citric acid One or more of iron, ferric phosphate, and ferrous oxalate; the phosphorus source is selected from one or more of ammonium dihydrogen phosphate, diammonium hydrogen phosphate, phosphoric acid, and lithium dihydrogen phosphate.

[0053] Wherein, the first carbon source is selected from one or more of glucose, sucrose, citric acid, polyethylene glycol, polyvinyl butyral, polyvinyl alcohol, polyacrylonitrile, starch, an...

Embodiment 1

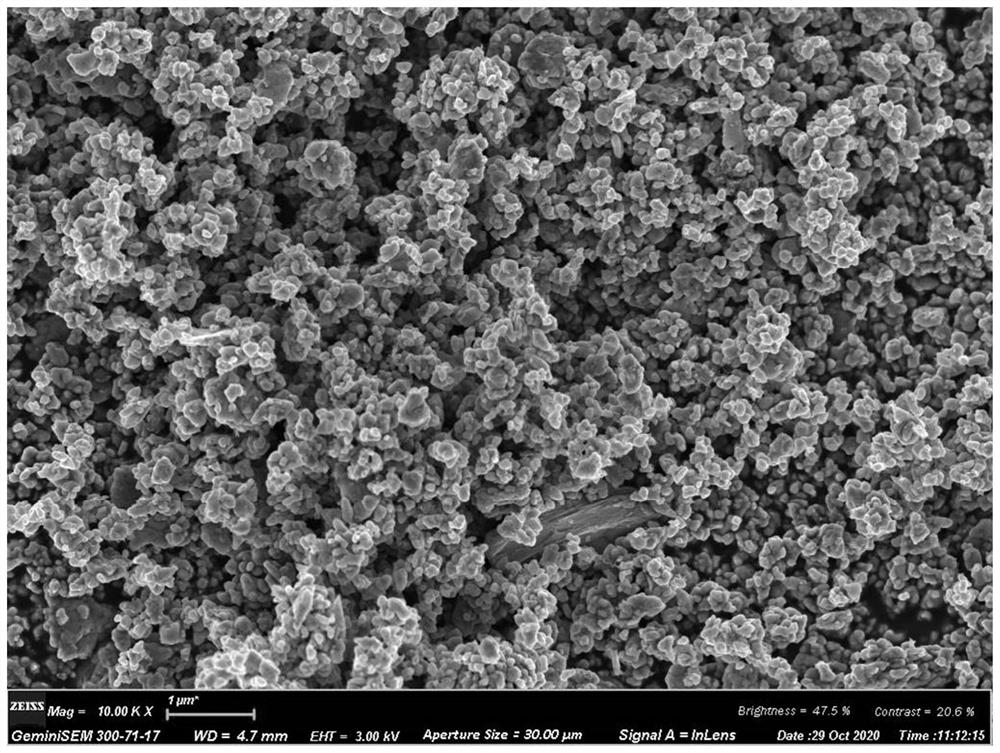

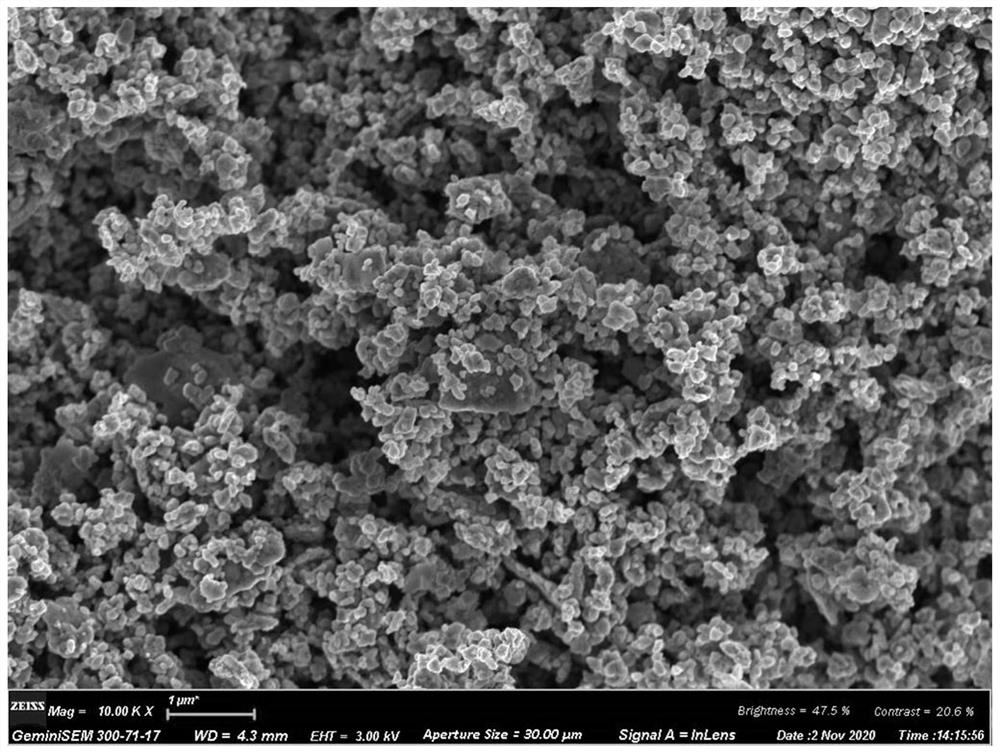

[0091] This embodiment provides a modified ultra-low temperature lithium iron phosphate composite material. The composite material includes a nanoscale undoped lithium iron phosphate core and a mixed cladding layer of lanthanum phosphate and carbon. The composition and weight percentage of the core core and cladding layer are as follows: Core undoped lithium iron phosphate: 95.55%, core carbon content: 1.95%; LaPO4 content in cladding layer: 2%, carbon content in cladding layer 0.5%.

[0092] The production process is as follows: ① Stir and disperse anhydrous iron phosphate, lithium carbonate and glucose with an appropriate proportion of water according to the mass ratio of 1:0.25:0.14; ② Grind with a grinder to control the grinding particle size of the slurry to D50 3. Spray drying; 4. The dried powder was roasted at 700 degrees under a nitrogen atmosphere for 8 hours to obtain control sample 1; 5. Control sample 1, lanthanum phosphate and glucose according to the mass ratio: ...

Embodiment 2

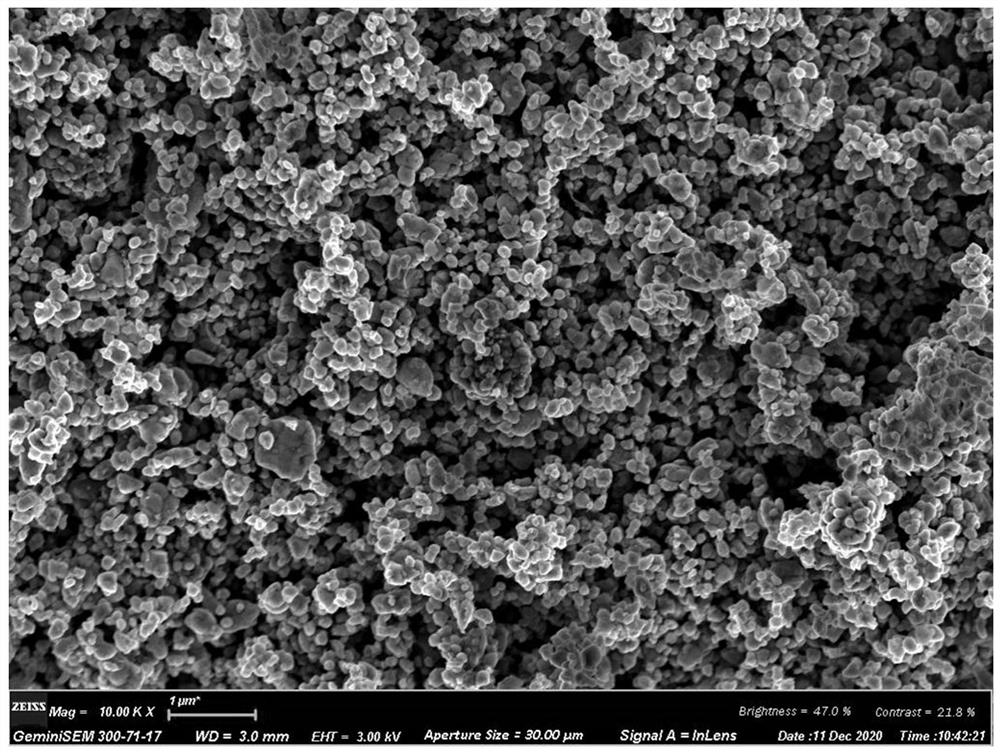

[0094] This embodiment provides a modified ultra-low temperature lithium iron phosphate composite material. The composite material includes a nanoscale doped lithium iron phosphate core and a mixed cladding layer of lanthanum phosphate and carbon. The composition and weight percentage of the core core and cladding layer are as follows: Core doped lithium iron phosphate: 95.55%, carbon content in the core: 1.95%; LaPO4 content in the cladding layer: 2%, carbon content in the cladding layer: 0.5%.

[0095] The production process is as follows: ① Stir and disperse anhydrous iron phosphate, lithium carbonate, ammonium metavanadate, and glucose with an appropriate proportion of water in a mass ratio of 1:0.25:0.01:0.14; ②Use a grinder to grind, Control the abrasive particle size D50 of the slurry to 0.45um; ③ spray drying; ④ roast the dried powder at 700°C for 8 hours under a nitrogen protective atmosphere to obtain comparative sample 2; The ratio of 1:0.02:0.025 is mixed with an a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com