Hook plowing type manufacturing process of band type commutator segment assembly

A manufacturing process and commutator piece technology, which is applied in the field of belt-type commutator piece group manufacturing technology, can solve the problems of large consumption of raw materials, high production costs, uneven width of inner hooks, etc., and achieve uniform depth of inner hook grooves and utilization of raw materials The effect of high rate and uniform inner hook width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

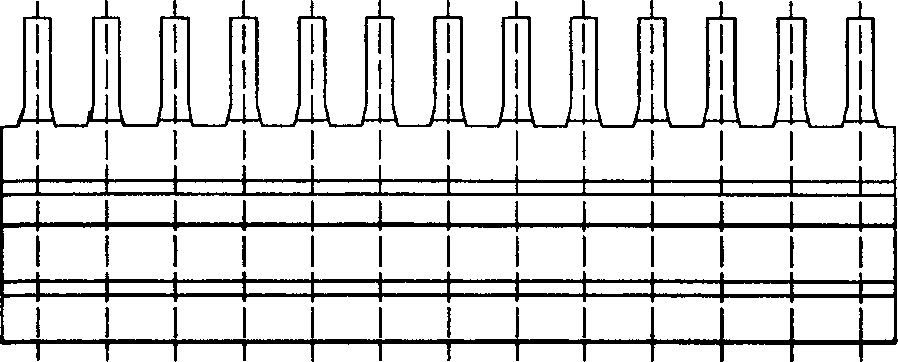

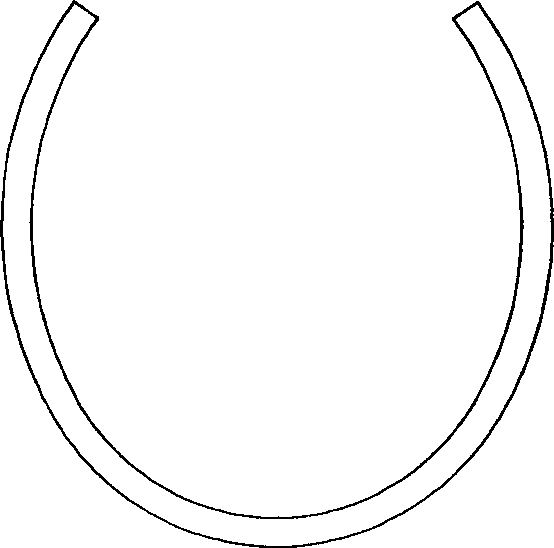

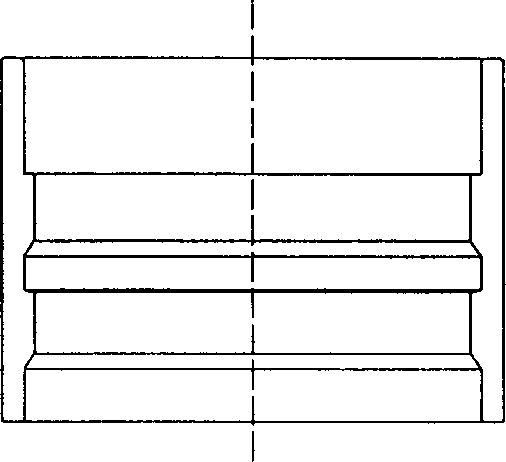

[0014] like Figure 1 to Figure 7 As shown, the plow-hook type manufacturing process of the belt-type commutator segment group of the present invention is: first carry out warm extrusion process to copper wire rod (i.e. solid circular tubular copper material) (using warm extrusion copper continuous extruder, warm extrusion The pressing temperature is generally 300-500 degrees Celsius, which is a known technology) to form a belt-type commutator group, and then draw the belt-type commutator group (secondary drawing, the drawing equipment used is a copper wire drawing machine) processing, and then blanking (using a punching machine with a tonnage of 40 tons), bending (secondary bending, using a punching machine, a tonnage of 10 tons) and rolling (using a Cold extrusion processing of punching machine, tonnage of 10 tons), plow inner hook (using h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com