Method for preparing peanut peptides through step enzymatic hydrolysis of peanut protein isolate by using two neutral proteases

A technology of peanut protein isolate and neutral protease, which is used in protein food ingredients, protein food processing, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

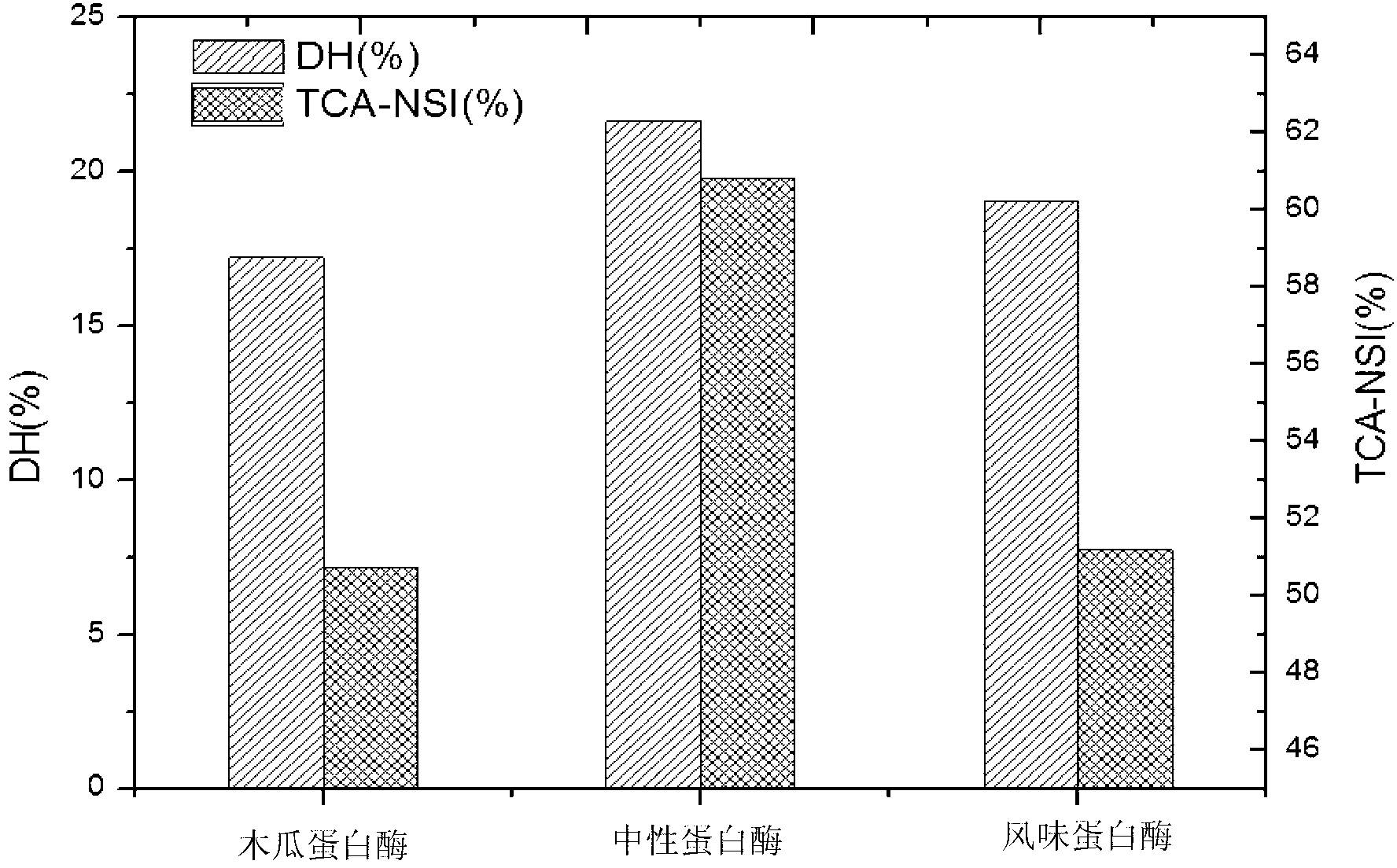

[0038] Embodiment 1, investigate the impact of different protease complexes on the degree of hydrolysis and the yield of short peptides

[0039] The first step: take peanut protein isolate powder, add distilled water to dissolve it, and obtain a peanut protein isolate solution with a mass concentration of 8%; add it to a constant temperature water bath at 80°C for 10 minutes, so that the peanut protein isolate has a highly compressed and compact structure Loosen, exposing the enzyme action site inside the molecule to facilitate the binding of protease;

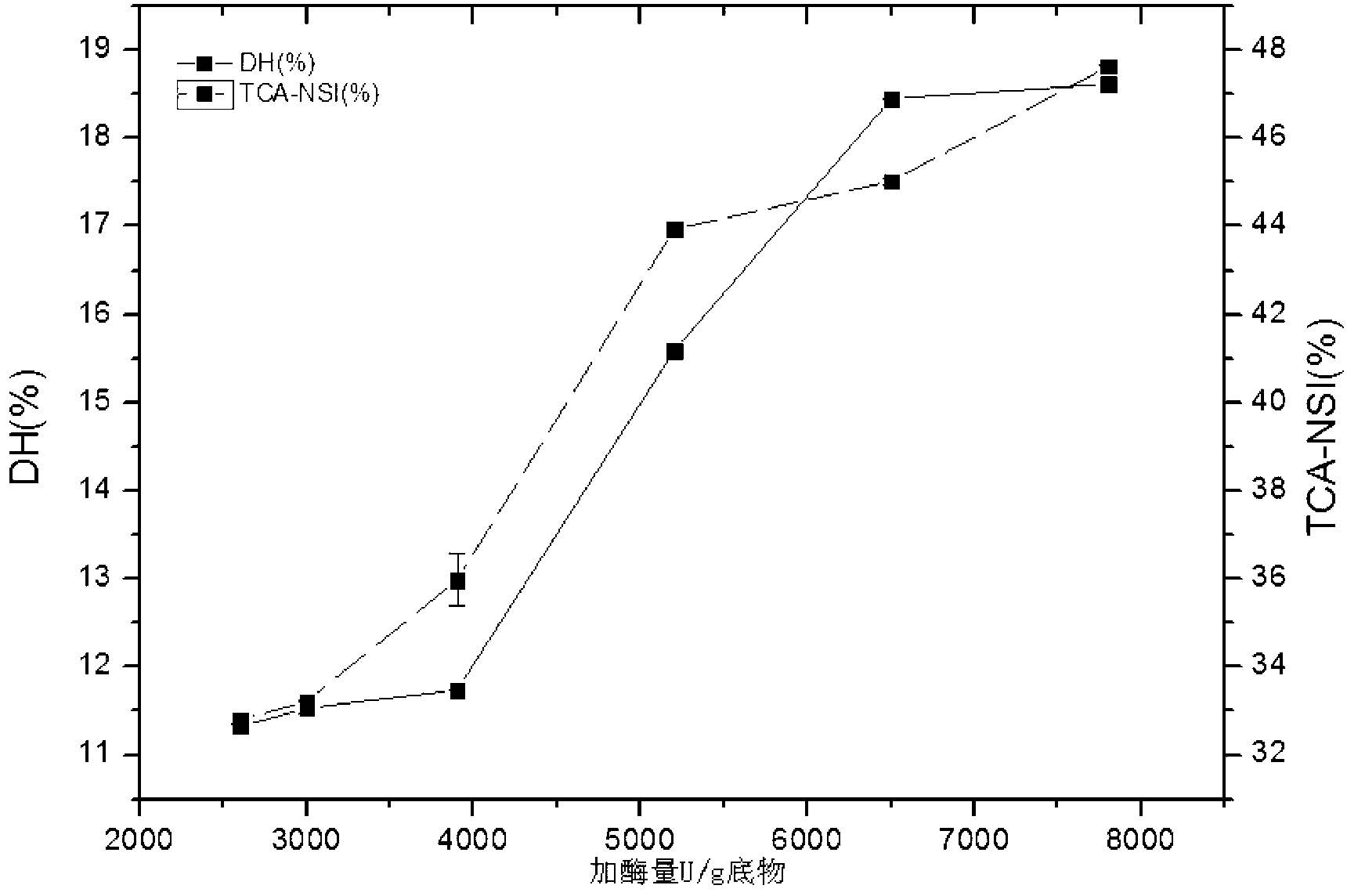

[0040] The second step: After the first step is completed, take out the peanut protein isolate solution, restore the temperature to the suitable temperature of neutral protease (45°C), add neutral protease (5200U / g substrate), and react in a constant temperature water bath shaker at 45°C 120min;

[0041] The third step: after the second step of the reaction, add the complex protease (432U / g substrate) and mix evenly, and cont...

Embodiment 2

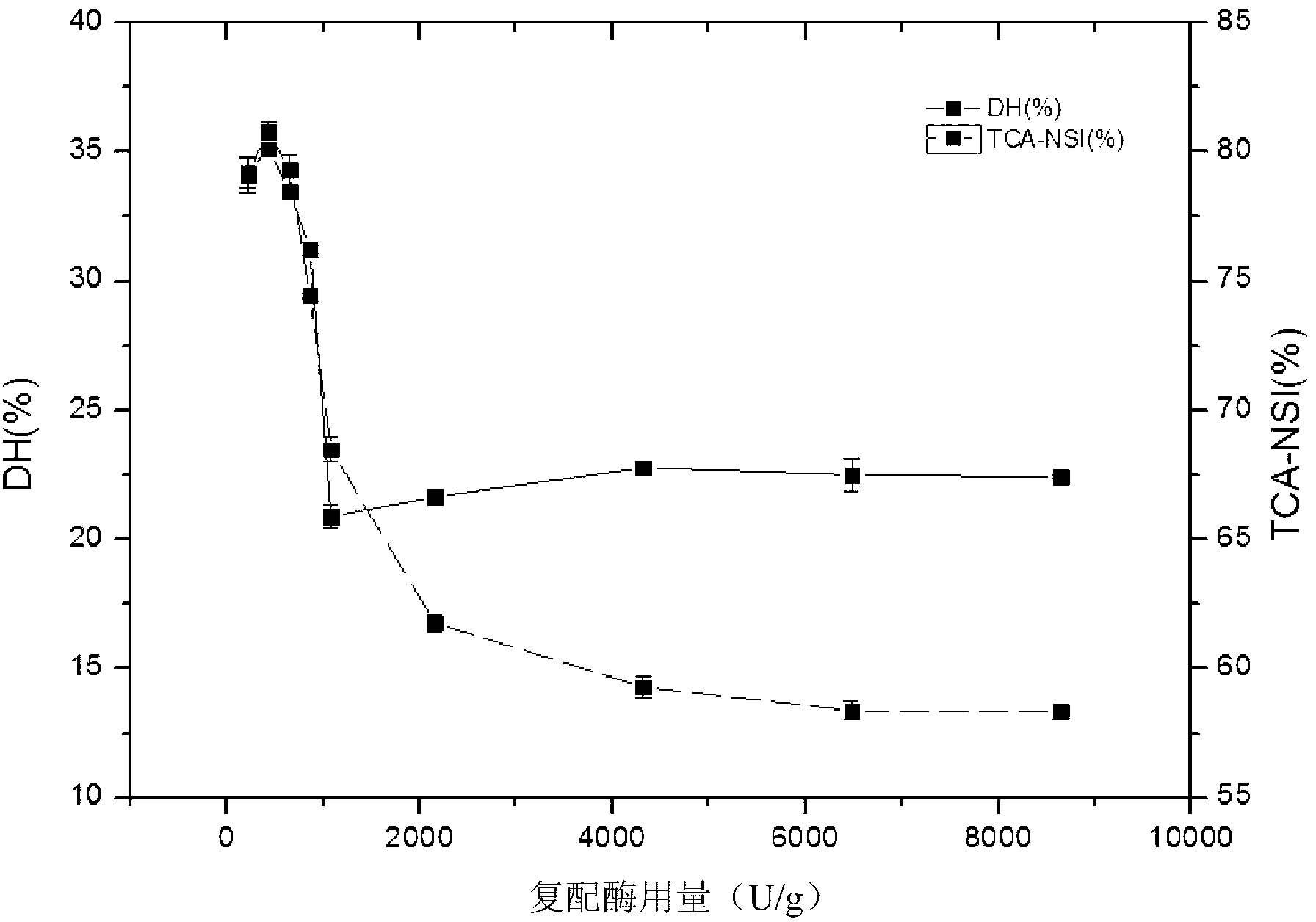

[0048] Embodiment 2, investigate the impact of compound protease dosage on degree of hydrolysis and short peptide yield

[0049] The first step: take peanut protein isolate powder, add distilled water to dissolve it, and obtain a peanut protein isolate solution with a mass concentration of 8%; add it to a constant temperature water bath at 80°C for 10 minutes, so that the peanut protein isolate has a highly compressed and compact structure Loosen, exposing the enzyme action site inside the molecule to facilitate the binding of protease;

[0050] The second step: After the first step is completed, take out the peanut protein isolate solution, restore the temperature to the suitable temperature of neutral protease (45°C), add neutral protease (5200U / g substrate), and react in a constant temperature water bath shaker at 45°C 120min;

[0051] Step 3: After the reaction in the second step, add different amounts of complex protease (216U / g substrate-8640U / g substrate) and mix evenl...

Embodiment 3

[0054] Example 3: Investigating the effects of different enzymatic hydrolysis temperatures on the degree of hydrolysis and the yield of short peptides

[0055] The first step: take peanut protein isolate powder, add distilled water to dissolve it, and obtain a peanut protein isolate solution with a mass concentration of 8%; add it to a constant temperature water bath at 80°C for 10 minutes, so that the peanut protein isolate has a highly compressed and compact structure Loosen, exposing the enzyme action site inside the molecule to facilitate the binding of protease;

[0056] The second step: After the first step is completed, take out the peanut protein isolate solution, restore the temperature to the suitable temperature of neutral protease (45°C), add neutral protease (5200U / g substrate), and react in a constant temperature water bath shaker at 45°C 120min;

[0057] Step 3: After the reaction in the second step, add complex protease (432U / g substrate) and mix evenly, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com