Method for connecting high-strength graphite with copper alloy

A technology of high-strength graphite and connection method, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of sample size limitation, high connection temperature, expensive equipment, etc., to achieve low connection cost, high strength, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

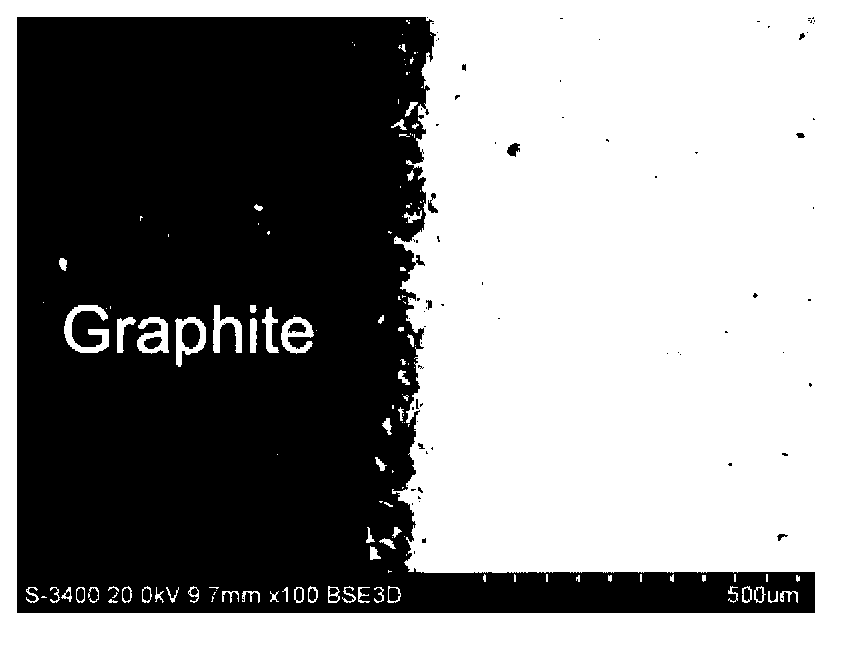

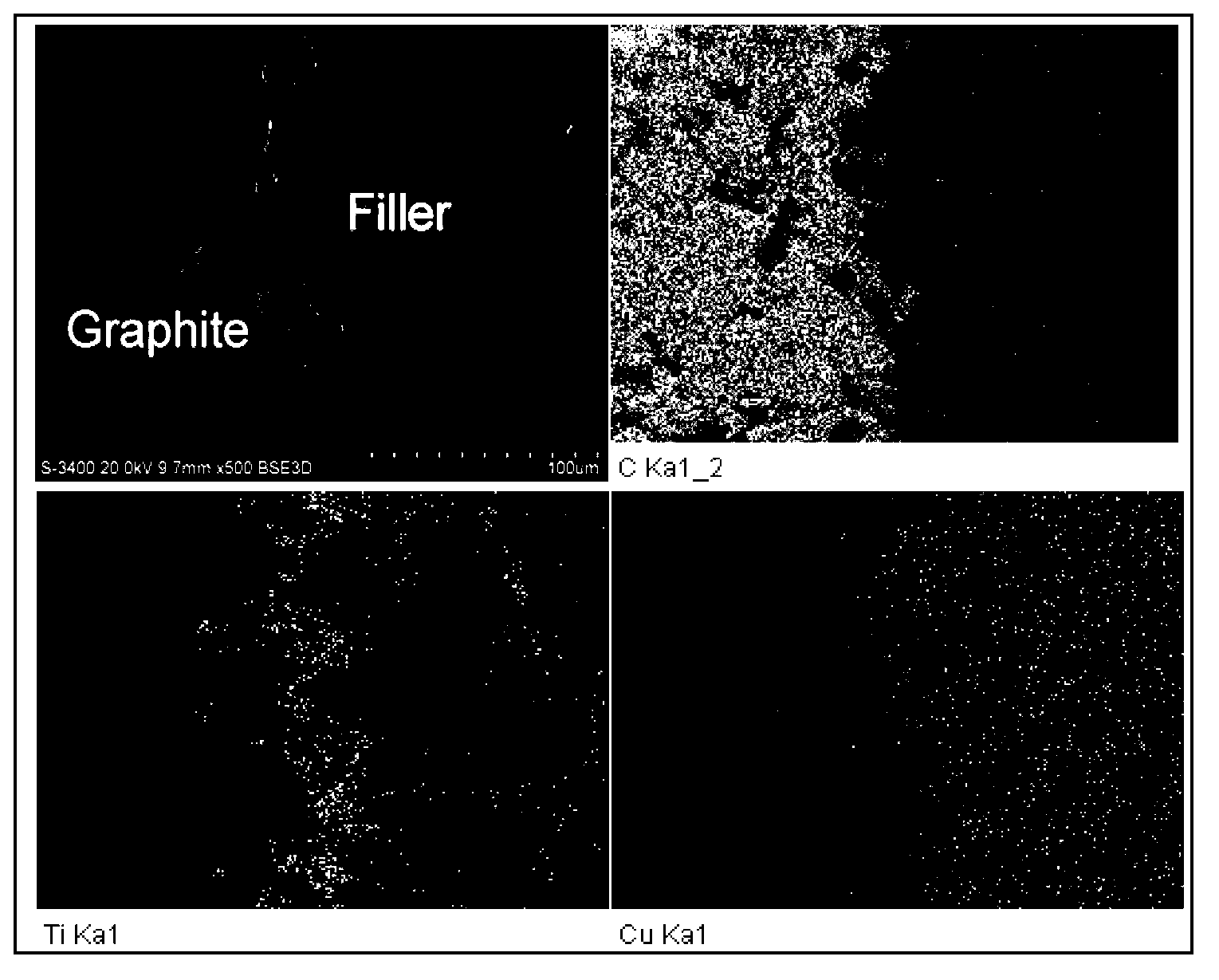

[0033] Apply the method provided by the invention to connect high-strength graphite (its bending strength is 40MPa) and CuCrZr alloy

[0034] Due to the poor wettability of CuCrZr alloy with high-strength graphite at high temperature, the preparation of joints is difficult.

[0035] The connection process of the high-strength graphite provided by the invention and the copper alloy is as follows:

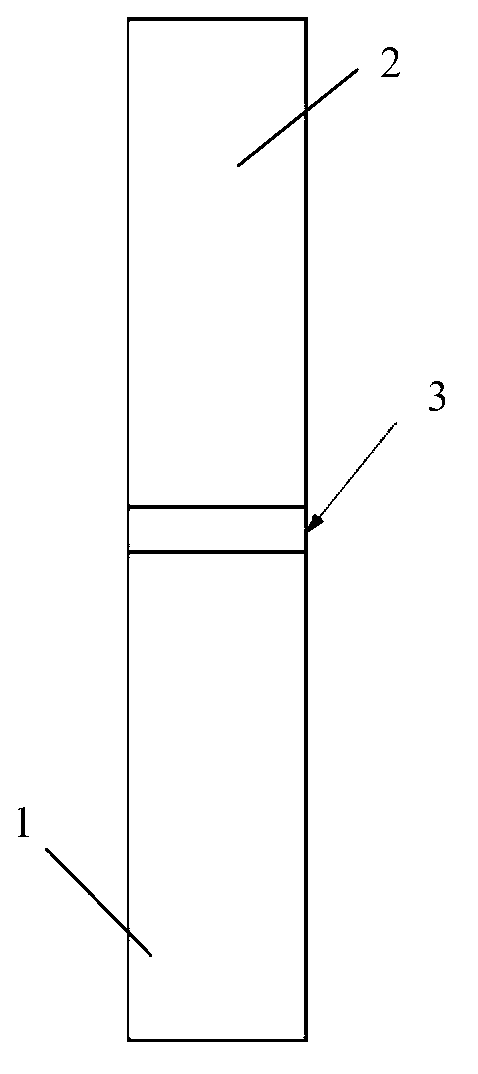

[0036] (A) pretreatment of the connection end face of high-strength graphite 1 and CuCrZr alloy 2;

[0037] Grind and polish the connection end face of high-strength graphite and CuCrZr alloy, clean it with ultrasonic waves for 20 minutes, then dry it for use;

[0038] (B) Preparation of solder;

[0039] Selecting Cu powder and Ti powder with a particle diameter of micron order, the particle diameters of the Cu powder and Ti powder are both 15-50 μm, mixing the Cu powder and the Ti powder, wherein the mass percentage of the Ti powder is 45%; The mixed powder was mixed in alcohol w...

Embodiment 2

[0047] Application of the method provided by the present invention to prepare high-strength graphite and red copper connectors in the new commutator of automobiles

[0048] The connection process of the high-strength graphite provided by the invention and the red copper is as follows:

[0049] (A) Pretreatment of high-strength graphite and copper connection end faces;

[0050] Grind and polish the connecting end face of high-strength graphite and copper, clean it with ultrasonic waves for 25 minutes, then dry it for use;

[0051] (B) Preparation of solder;

[0052] Selecting Cu powder and Ti powder with a particle diameter of micron order, the particle diameters of the Cu powder and Ti powder are both 15-50 μm, mixing the Cu powder and the Ti powder, wherein the mass percentage of the Ti powder is 50%; The mixed powder was mixed in alcohol with ultrasonic vibration for 30min. In order to avoid stratification due to different powder densities, it should be stirred at any time ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com