Transfer method of graphite film

A transfer method and graphene technology, applied in the field of material processing, can solve problems such as damage, high cost, and multiple pollutants in the graphene layer, and achieve the effects of reducing production costs, improving quality, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

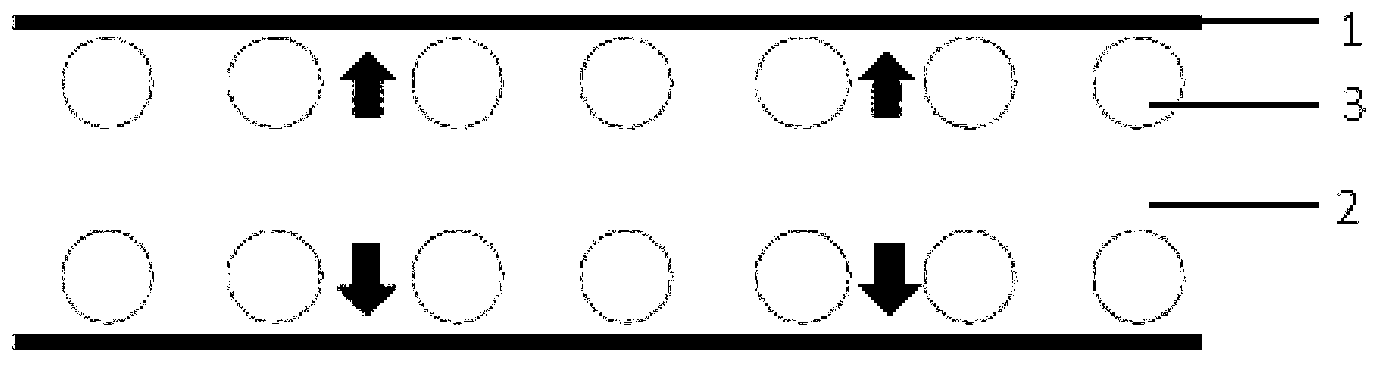

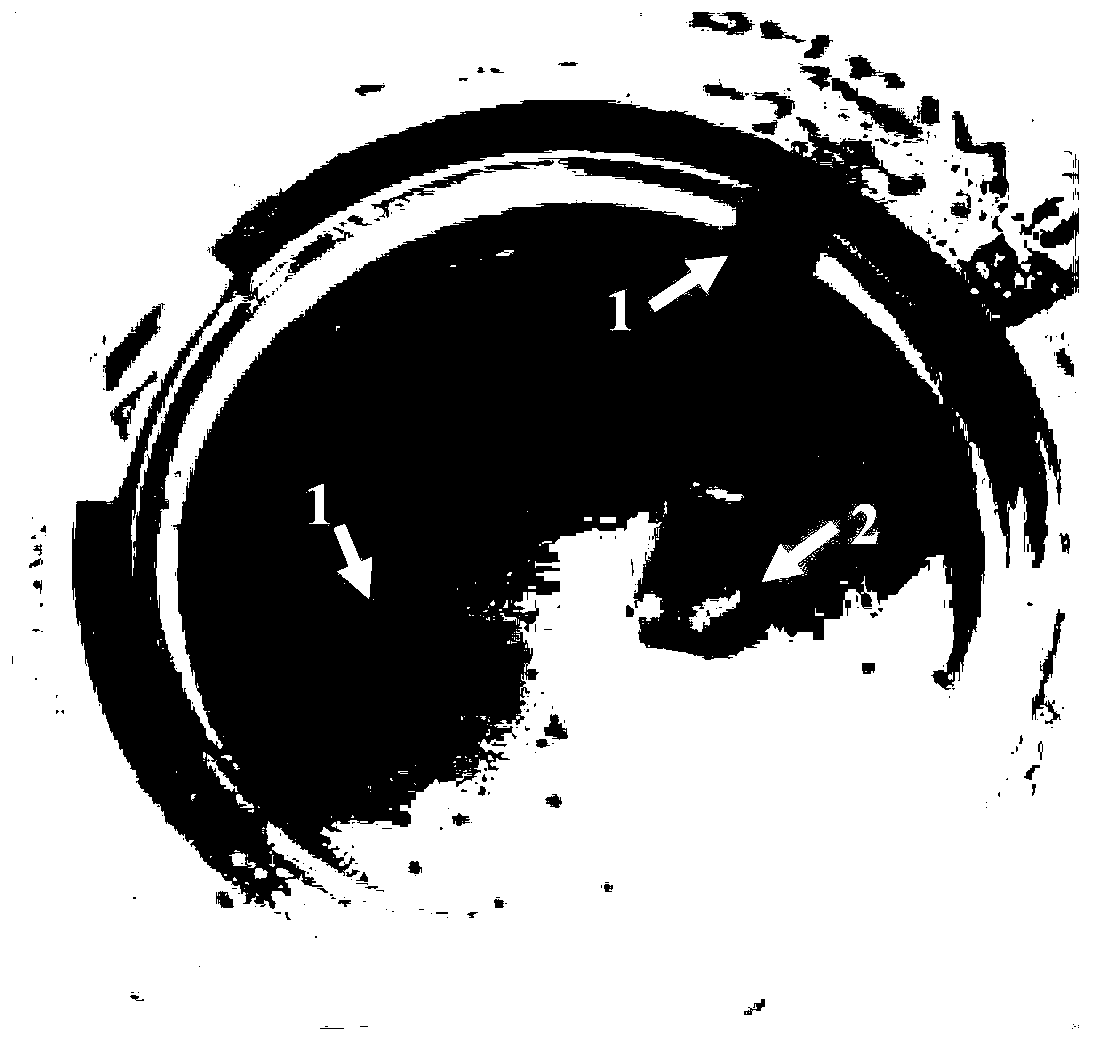

Method used

Image

Examples

Embodiment Construction

[0028] The following examples illustrate the present invention, but these examples should not be construed as limiting the present invention.

[0029] Take graphene prepared by transferring nickel thin film with hydrochloric acid solution as an example:

[0030] 1. Pretreatment of nickel thin film

[0031] Metal nickel film (50nm-1mm) is used as a catalyst for CVD growth of graphene, and the surface of the nickel film is treated with acetone, ethanol and dilute hydrochloric acid to remove metal oxides, oil and other impurities.

[0032] 2. Prepare a single-layer, double-layer or more than three-layer graphene layer (thickness can reach less than micron) on the nickel film.

[0033] A graphene layer was prepared on a nickel film by chemical vapor deposition. The carbon source used was methane (CH 4 ), the other auxiliary gas in the reaction is hydrogen H 2 And argon Ar, in which hydrogen plays a reducing role and argon plays a protective role.

[0034] (1) Put the treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com