System and method for recycling tin from tin-stripping waste liquid and circularly preparing novel tin-stripping liquid

A technology of waste liquid recovery and electrical control system, applied in the direction of improving process efficiency, etc., can solve the problems of complex combination process, easy loss of electrodes, high maintenance cost, and achieve the effects of high tin dissolution rate, low corrosion and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

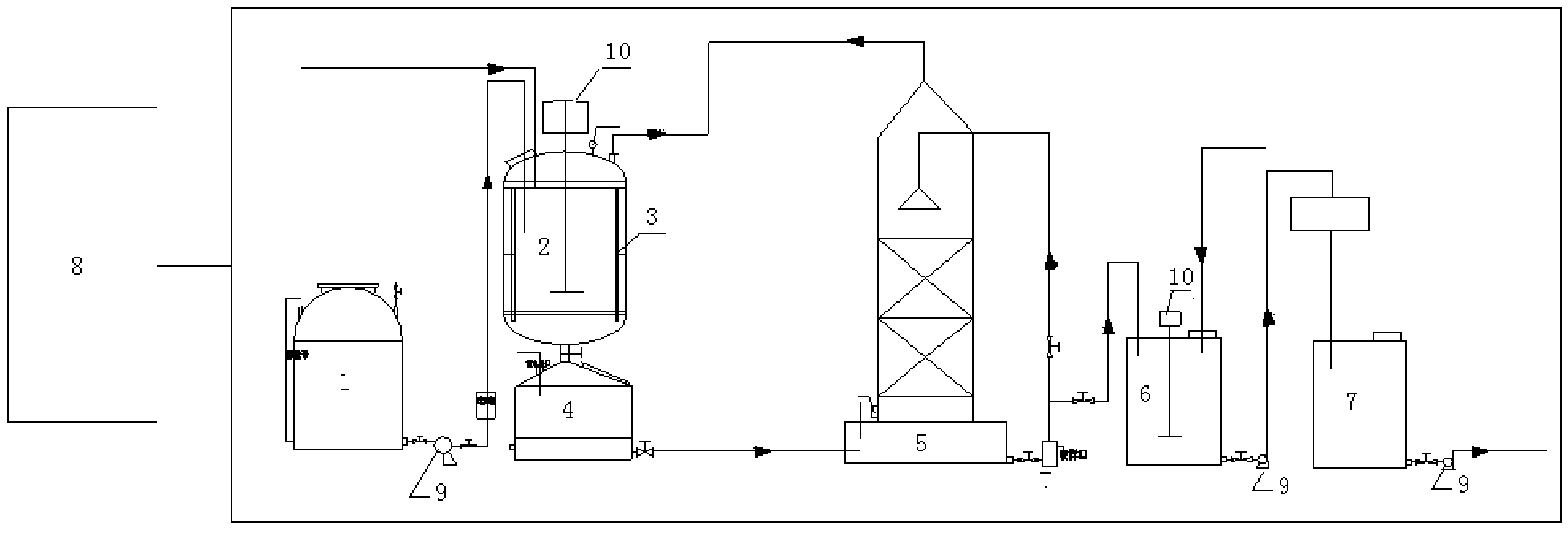

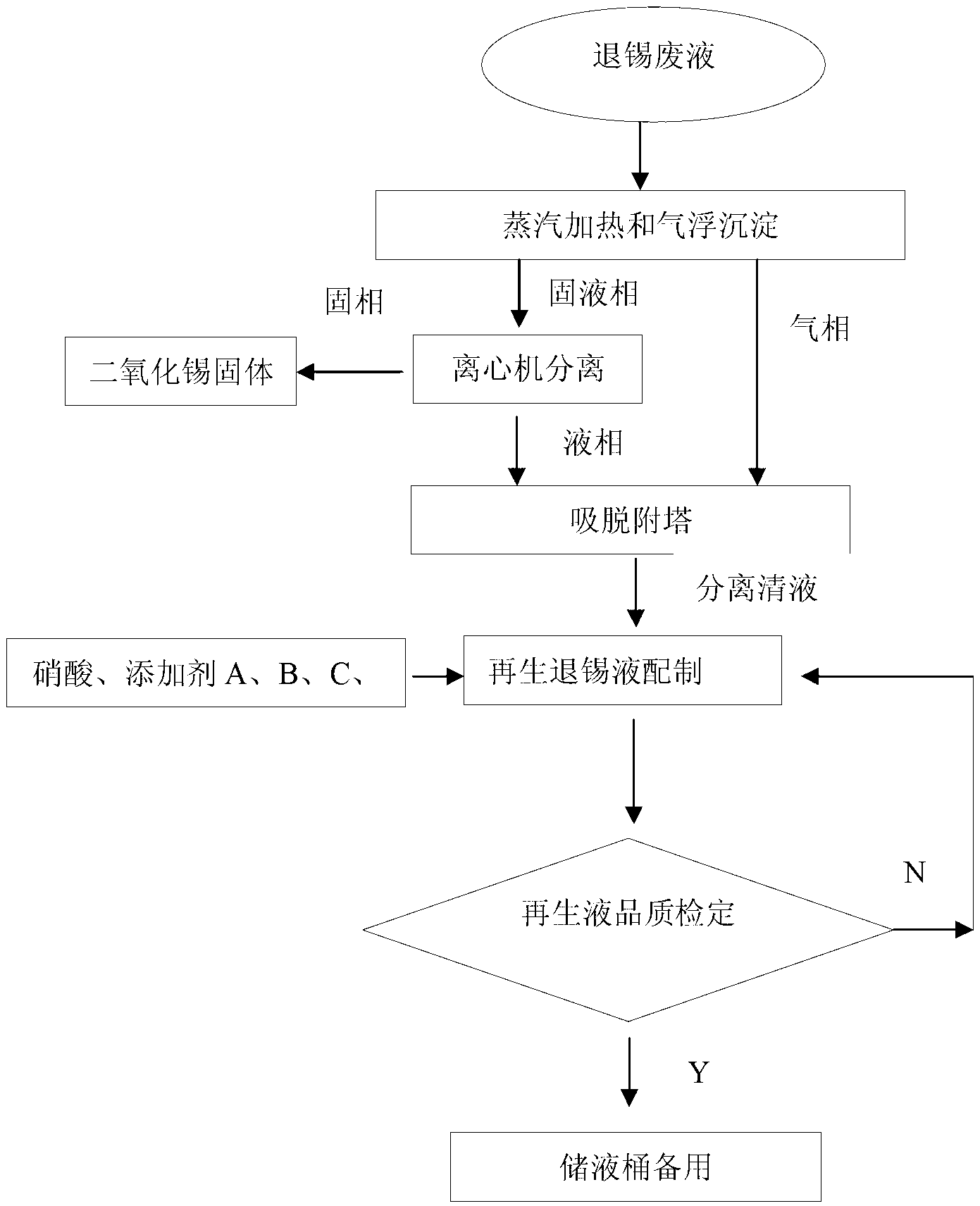

Method used

Image

Examples

specific Embodiment example 1

[0037] The tin-removing waste liquid from a circuit board factory in Jiangsu has been determined to contain 15% nitric acid, 150g / L tin, 2.1g / L copper, and a specific gravity of 1.35. Take 1L of waste liquid, pass it through steam for hydrolysis and air flotation for 20 minutes, and centrifuge After separation for 3 minutes, 900ml of clear liquid was obtained, containing 0.5g / L tin and 1.5g / L copper. Add 40ml of 68% nitric acid, 3ml of wetting acceleration additive A, 2ml of copper-protecting additive B, and 2ml of stability and precipitation inhibitory additive C, and stir thoroughly for 30 minutes to obtain 945ml of liquid with a specific gravity of 1.21. Using the soaking method to remove tin, the temperature of the regenerated tin stripping water is controlled at 30°C, the rate of tin stripping reaches 12u / min, and the stripping rate reaches 2.8m 2 The performance of tin plate meets the standard of fresh tin stripping water, and at the same time, it realizes the complete r...

specific Embodiment example 2

[0039] The tin-removing waste liquid from a circuit board factory in Shanghai has been determined to contain 13.8% nitric acid, 78g / L tin, 7.6g / L copper, and 10g / L iron. Float and separate for 25 minutes, and centrifuge for 5 minutes to obtain 920ml of clear liquid containing 0.6g / L tin and 3.2g / L copper. Add 30ml of 68% nitric acid, 3ml of wetting acceleration additive A, 2ml of copper-protecting additive B, and 2ml of stabilization and precipitation inhibitory additive C, and stir thoroughly for 30 minutes to obtain 955ml of liquid with a specific gravity of 1.23. Using the soaking method to remove tin, the temperature of the regenerated tin stripping water is controlled at 30°C, the rate of tin stripping reaches 11.8u / min, and the stripping rate reaches 2.9m 2 The performance of tin plate meets the standard of fresh tin stripping water, and at the same time, it realizes the complete recycling and reuse of tin stripping waste liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com