Lateral growth ZnMgO nanowire solar-blind region ultraviolet detector and fabrication method thereof

An ultraviolet detector and lateral growth technology, which is applied in the field of photoelectric detection, can solve the problems of difficulty in the fabrication of device electrodes, difficulty in integrating the device with other semiconductor devices, etc., and achieves the effects of an effective fabrication method, high photocurrent gain, and a simple fabrication process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

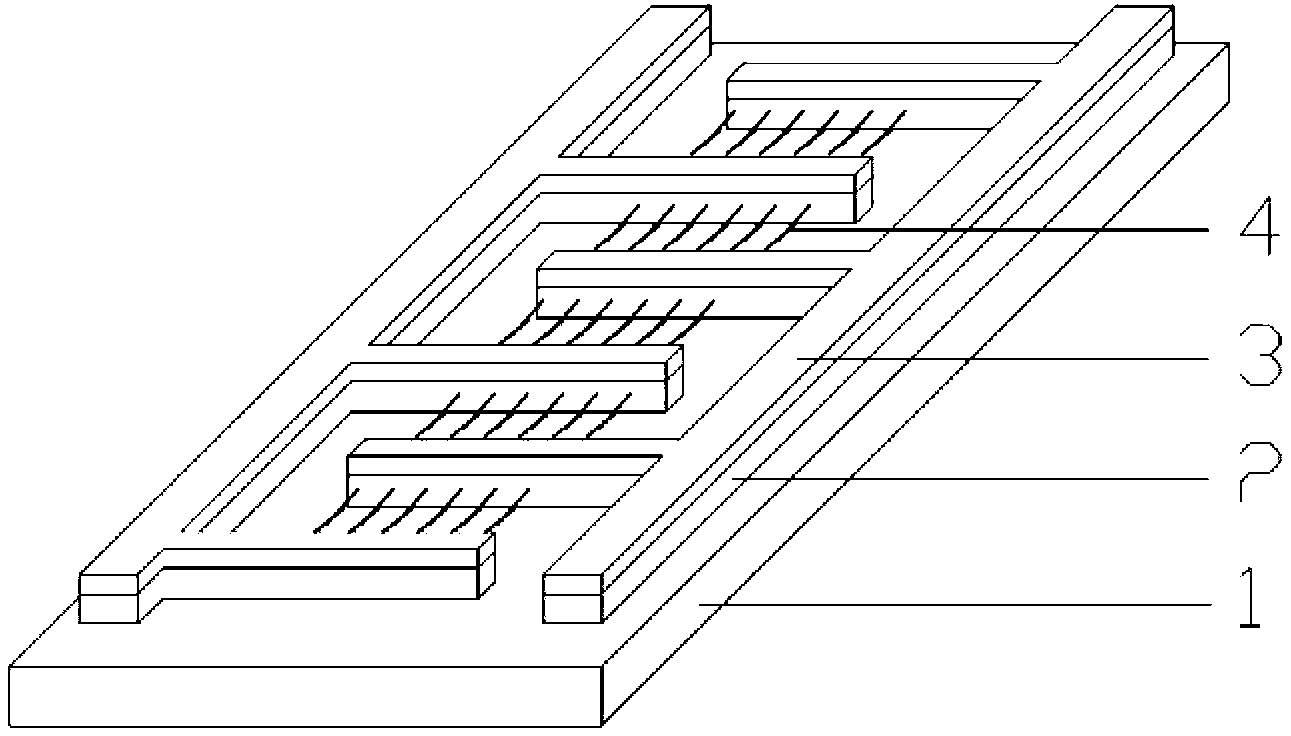

[0022] a. Use quartz material as an insulating substrate, clean it with ultrasonic vibration in deionized water, absolute ethanol, and acetone for 10 minutes, and dry it with nitrogen;

[0023] b. A ZnO film seed layer with a thickness of about 150nm is grown on a quartz substrate by pulsed laser deposition technology;

[0024] c. Use a vacuum coating machine to coat a layer of gold film with a thickness of about 50 nm on the surface of the ZnO thin film seed layer as an electrode.

[0025] d. Etch the ZnO thin film seed layer and the gold electrode into interdigitated shapes with a length of 500 μm, a width of 5 μm, and a spacing of 5 μm by using traditional photolithography and lift-off technology.

[0026] e. Put the above electrode into a hydrothermal reaction kettle, and grow ZnMgO nanowires on the side of the interdigitated ZnO seed layer by hydrothermal method. Obtain a solar-blind zone ultraviolet detector grown laterally with ZnMgO nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com