Active carbon regeneration absorption device and active carbon regeneration absorption technology

An adsorption device and activated carbon technology, which is applied in filter regeneration, adsorption water/sewage treatment, petroleum industry, etc., can solve the problems of industrialization promotion and application limitations, decreased adsorption capacity of activated carbon, and low utilization rate of regeneration energy, etc., achieving low cost, Short regeneration time and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

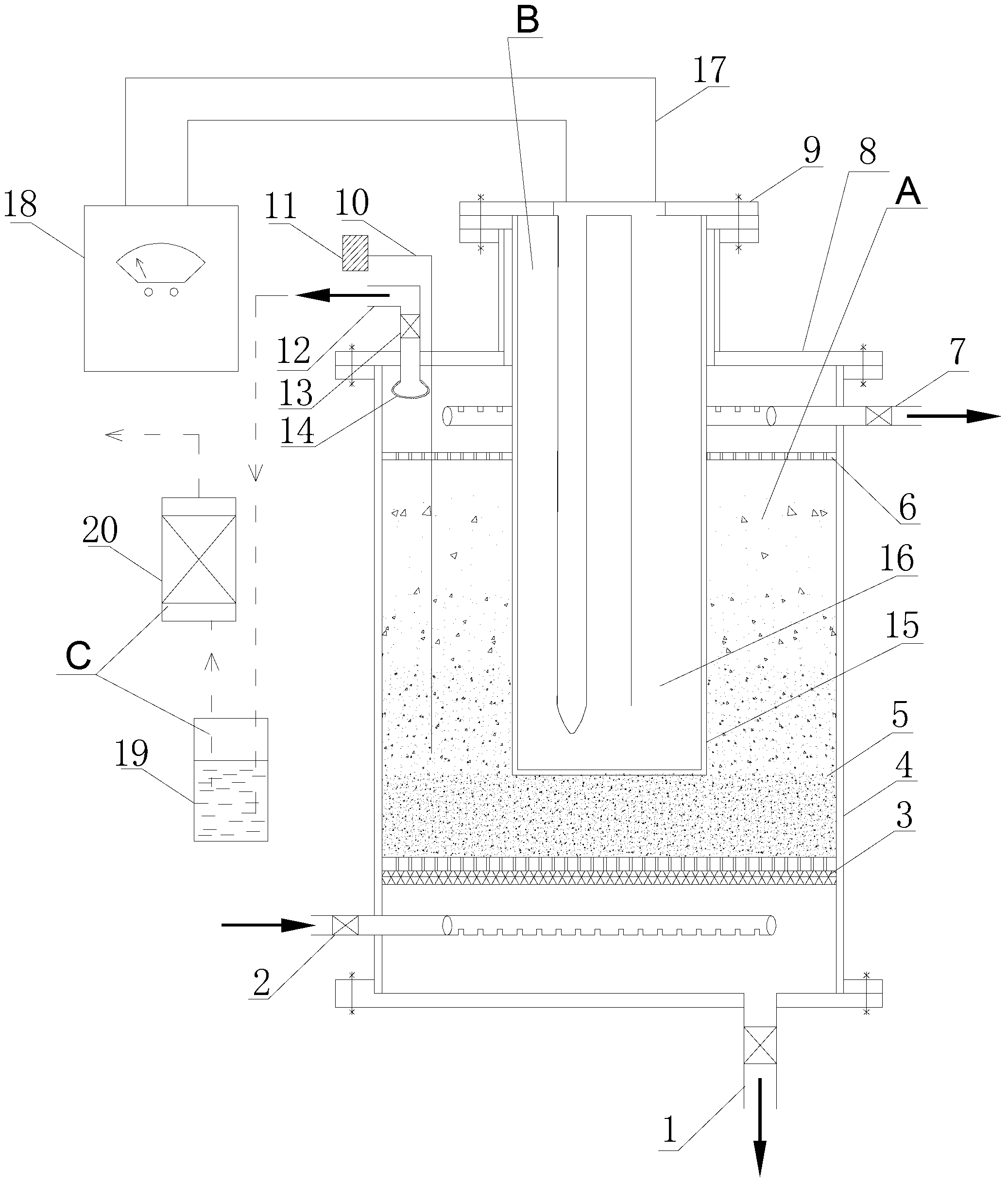

[0039] The schematic diagram of the cross-sectional structure of the activated carbon regeneration adsorption device is as follows: figure 1 Shown: It is mainly composed of adsorption tower system A, energy system B and tail gas absorption system C. Among them, the adsorption tower system A is composed of the outer sleeve of the adsorption tower 4, the water inlet distribution pipe 2, the support plate 3, the activated carbon bed 5, the baffle plate 6, the water outlet pipe 7, the first cover plate 8, and the second cover plate 9. There is a thermocouple 10 inside the outer sleeve 4 of the tower, and the thermocouple 10 is connected with the temperature digital display 11, and the gas outlet 12, the pneumatic safety valve 13 and the nozzle 14 are connected; the energy system B is composed of an energy probe 16 and an energy probe protection sleeve 15. The energy conduit 17 and the energy generator 18 are composed, wherein the energy probe 16 is placed in the energy probe prote...

Embodiment 2

[0041] The activated carbon regeneration adsorption device is mainly composed of adsorption tower system A, energy system B and tail gas absorption system C. Among them, the adsorption tower system A is composed of the outer sleeve 4 of the adsorption tower, the water inlet pipe 2, the support plate 3, the activated carbon bed layer 5, the baffle plate 6, the water outlet pipe 7, the cover plate 8, and the second cover plate 9. The sleeve 4 is provided with a thermocouple 10, and the thermocouple 10 is connected to the temperature digital display 11, and the gas outlet 12, the pneumatic safety valve 13 and the nozzle 14 are connected to form; the energy system B consists of an energy probe 16, an energy probe protection sleeve 15, The energy conduit 17 and the energy generator 18 are composed, wherein the energy probe 16 is placed in the energy probe protection sleeve 15, the energy probe 16 is connected to the energy generator 18 through the energy conduit 17, and the energy p...

Embodiment 3

[0043] Activated carbon adsorption and regeneration treatment of simulated high-concentration phenol wastewater using a set of activated carbon regeneration adsorption device (such as Example 1)

[0044] Using 1500mg / L high-concentration simulated phenol wastewater requires that the effluent concentration be lower than 150mg / L after adsorption treatment by the activated carbon regeneration adsorption device, and the activated carbon adsorption capacity recovers to more than 85% of its initial value after regeneration. The activated carbon regeneration adsorption device in Example 1 of the present invention is used to carry out the adsorption-regeneration-adsorption treatment experiment of phenol simulated wastewater, and the steps include:

[0045] a) Install activated carbon, the activated carbon adopts coconut shell activated carbon, the particle size is 8-14 mesh, and the activated carbon filling height is 800mm;

[0046] b) Adsorption treatment, the simulated wastewater is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com