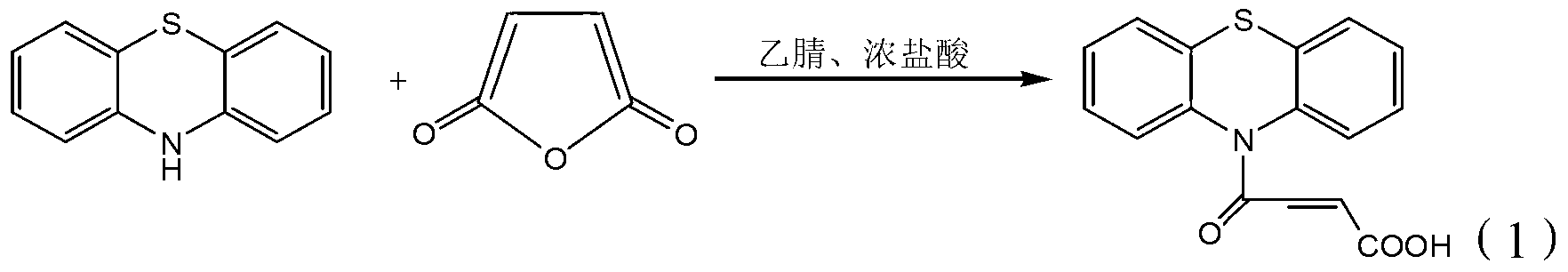

Method for preparing 4-(N-phenothiazine)-carbonyl-2-butenoic acid

A technology of phenothiazine and crotonic acid, which is applied in the direction of organic chemistry, can solve the problems of troublesome post-processing, high reaction temperature, and long time, and achieve the effects of short reaction time, easy-to-obtain raw materials, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the first step, add 0.0025mol of phenothiazine and 0.0025mol of maleic anhydride to a dry three-necked flask, then add 10mL of acetonitrile, and slowly add 0.2mL of mass concentration to the reaction vessel at a stirring speed of 1500r / min. 36-38% concentrated hydrochloric acid to obtain a reaction solution. The reaction solution was heated from room temperature at a rate of 3 °C / min to 40 °C, and stirred at a rate of 1500 r / min for 2.5 hours to obtain a mixed solution;

[0023] In the second step, the acetonitrile is evaporated from the mixed solution under reduced pressure to obtain a concentrated solution. The volume of acetonitrile in the concentrated solution is 15% of the volume of acetonitrile in the mixed solution. After the concentrated solution is cooled to room temperature, 10 mL of water is added thereto, stirred for 5 minutes, and pumped. Filter, wash the filter cake with water, and dry at room temperature to obtain a white powder that is 4-(N-phenothiazi...

Embodiment 2

[0026] In the first step, add 0.0025mol of phenothiazine and 0.0028mol of maleic anhydride to a dry three-necked flask, then add 10mL of acetonitrile, and slowly add 0.15mL of mass concentration to the reaction vessel at a stirring speed of 2200r / min. 36-38% concentrated hydrochloric acid to obtain a reaction solution, the reaction solution was heated from room temperature at a rate of 4 °C / min to 50 °C, and stirred at a rate of 2200 r / min for 2.5 hours to obtain a mixed solution;

[0027] In the second step, the acetonitrile is evaporated from the mixed solution under reduced pressure to obtain a concentrated solution. The volume of acetonitrile in the concentrated solution is 20% of the volume of acetonitrile in the mixed solution. After the concentrated solution is cooled to room temperature, 10 mL of water is added thereto, stirred for 5 minutes, and pumped. Filter, wash the filter cake with water, and dry at room temperature to obtain a white powder that is 4-(N-phenothiaz...

Embodiment 3

[0029] In the first step, add 0.00250mol of phenothiazine and 0.00275mol of maleic anhydride to a dry three-necked flask, then add 12mL of acetonitrile, and slowly add 0.2mL of mass concentration to the reaction vessel at a stirring speed of 1700r / min. 36-38% concentrated hydrochloric acid to obtain a reaction liquid, the reaction liquid was heated from room temperature at a rate of 3 °C / min to 60 °C, and stirred at a speed of 1700 r / min for 2 hours to obtain a mixed liquid;

[0030] In the second step, the acetonitrile is evaporated from the mixed solution under reduced pressure to obtain a concentrated solution. The volume of acetonitrile in the concentrated solution is 17% of the volume of acetonitrile in the mixed solution. After the concentrated solution is cooled to room temperature, 15 mL of water is added thereto, stirred for 7 minutes, and then pumped. Filter, wash the filter cake with water, and dry at room temperature to obtain a white powder that is 4-(N-phenothiazi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com