Integrated recovery method of waste and old rare earth capacitance battery

A capacitor battery and recycling method technology, applied in the direction of improving process efficiency, etc., can solve the problems that it cannot be used as a power battery electrode material, the electrochemical performance of nickel hydroxide is general, and the process environmental protection is low, and achieves low price and particle size distribution. The effect of uniformity and high recovery purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

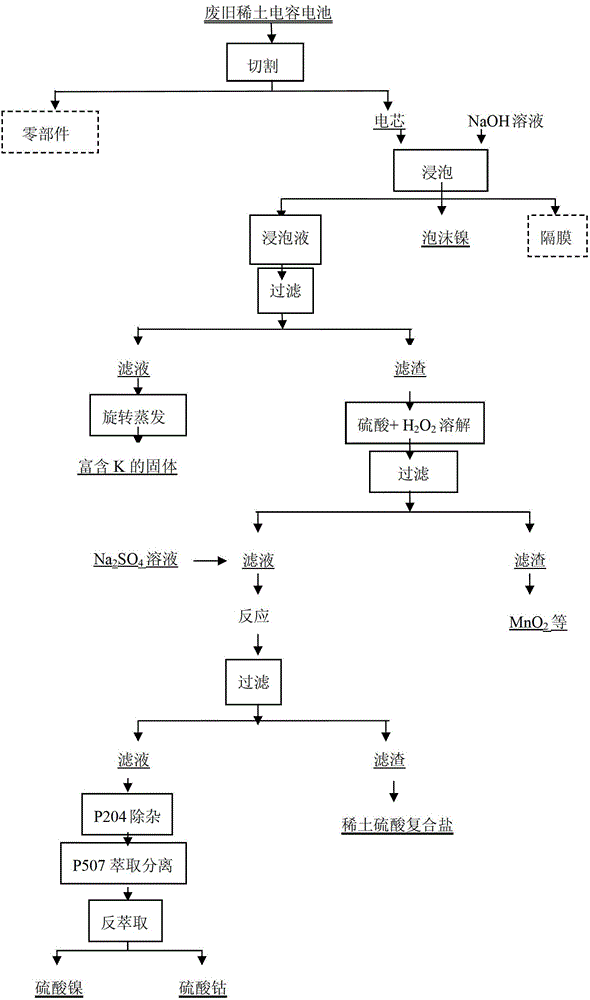

Image

Examples

Embodiment 1

[0046] a. Cut the waste rare earth capacitor battery and separate the battery cell and parts:

[0047] Use a laser cutting machine to cut waste rare earth capacitor batteries, take out the battery core including the plate and diaphragm, and take out the parts including the battery case, top cover, safety valve, pole, lug, nut, flat gasket and gasket.

[0048] b. Ultrasonic soak the cell with NaOH, and then separate the diaphragm and nickel foam to obtain the soaking solution:

[0049] Soak the cell and pure water at a mass ratio of 1:0.8, then add NaOH for ultrasonic soaking, the ratio of NaOH to pure water is 0.1:1, NaOH is measured in moles, and pure water is measured in L. Use 2000W ultrasonic power to intermittently ultrasonicate 4 times, the cumulative time is 20min, the soaking temperature is 75°C, and the soaking time is 1h, then take out the foamed nickel from which the electrode material has been separated, wash and dry, take out the diaphragm, wash and dry, and the r...

Embodiment 2

[0058] a. Cut the waste rare earth capacitor battery and separate the battery cell and parts:

[0059] Use a laser cutting machine to cut waste rare earth capacitor batteries, take out the battery core including the plate and diaphragm, and take out the parts including the battery case, top cover, safety valve, pole, lug, nut, flat gasket and gasket.

[0060] b. Soak the cell with NaOH, then separate the diaphragm and nickel foam to obtain the soaking solution:

[0061] Soak the cell and pure water at a mass ratio of 1:1, and then add NaOH for ultrasonic soaking. The ratio of NaOH to pure water is 0.2, NaOH is measured in mol, and pure water is measured in L. Use 1000W ultrasonic power to ultrasonicate 8 times intermittently, the cumulative time is 30min, the soaking temperature is 40°C, and the soaking time is 3h, then take out the foamed nickel from which the electrode material has been separated, wash and dry, take out the diaphragm, wash and dry, and the rest is the soakin...

Embodiment 3

[0070] a. Cut the waste rare earth capacitor battery and separate the battery cell and parts:

[0071] Use a laser cutting machine to cut waste rare earth capacitor batteries, take out the battery core including the plate and diaphragm, and take out the parts including the battery case, top cover, safety valve, pole, lug, nut, flat gasket and gasket.

[0072] b. Soak the cell with NaOH, then separate the diaphragm and nickel foam to obtain the soaking solution:

[0073] Soak the cell and pure water at a mass ratio of 1:1, add NaOH for ultrasonic soaking, the ratio of NaOH to pure water is 0.15:1, NaOH is measured in mol, and pure water is measured in L. Use 1500W ultrasonic power to ultrasonicate 6 times intermittently, the cumulative time is 25min, the soaking temperature is 60°C, and the soaking time is 2h, then take out the nickel foam that has been separated from the electrode material, wash and dry, take out the diaphragm, wash and dry, and the rest is the soaking solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com