Preparation method of acellular pertussis vaccine

A pertussis and toxin technology, which is applied in the field of acellular pertussis vaccine preparation, can solve the problems of difficult to exceed 70% yield, conflict between purity and yield, existence of safety, etc., and achieves easy large-scale scale-up production and good stability. , the effect of high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

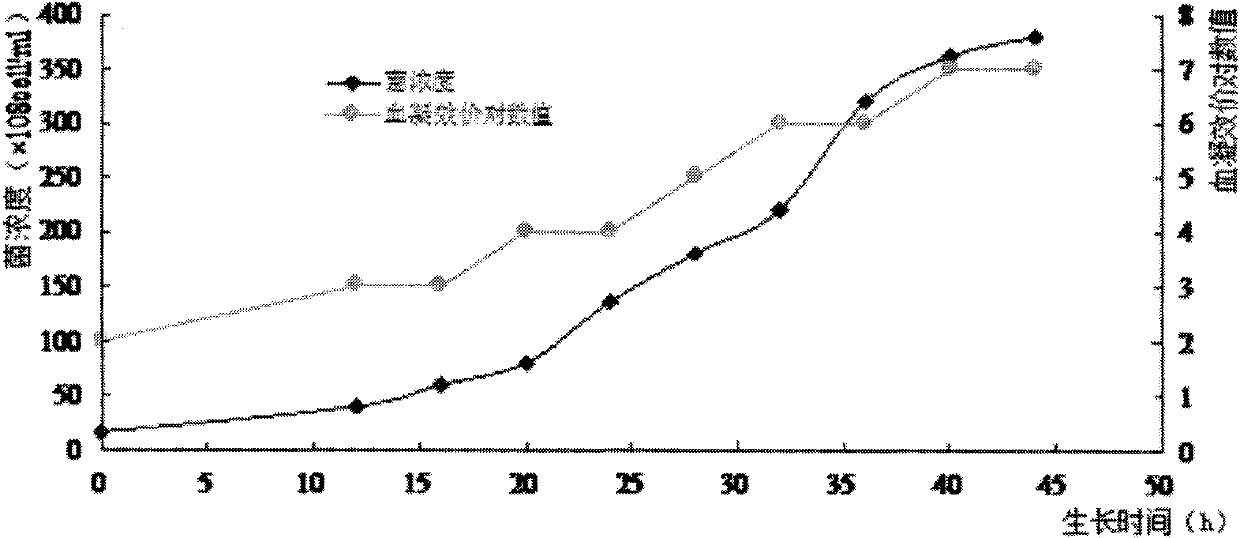

[0062] Example 1. Fermentation of Bacillus pertussis

[0063] experiment material:

[0064] Species: Bordetella pertussis CS phase I strain

[0065] Medium: Improved SS liquid medium: SS liquid medium with 0.25% acid hydrolyzed casamino acids and 0.1% β-cyclodextrin

[0066] Rehydration: sodium glutamate 4g / L, acid hydrolyzed casamino acids 2g / L, pH7.6

[0067] Main equipment: 40L fermenter (BIO-FLOW5000, NBS), 300L fermenter (BIOF-6300B 300L, Shanghai Gaoji Biological Engineering Co., Ltd.)

[0068] experiment method:

[0069] Put the freeze-dried bacterial species of pertussis CS strain on sheep blood abalone ginger agar medium containing 25% defibrillation, culture at 37°C for 72 hours, transfer to activated carbon agar medium, and cultivate at 37°C for 48 hours; pass 3 Generation (activated carbon agar medium), after continuing to culture at 37°C for 48 hours, scrape seeds in 150ml phosphate buffer (ie PBS buffer, 137mM NaCl, 2.7mMKCl, 10mMNa 2 HPO 4 , 2mM KH 2 PO ...

Embodiment 2

[0072] Embodiment 2. The ultrafiltration treatment of fermented liquid

[0073] Test materials and samples:

[0074] Hollow fiber filter column: UFP-10 / 30-C-4MA-0.065m2, GE

[0075] Tangential flow treatment system: Quixstand hollow fiber membrane separation system, GE

[0076] Sample: Bacterial fluid harvested from pertussis fermentation, supernatant after centrifugation or other methods to separate the bacterial cells, and filtered through a 0.22 μm filter membrane to remove impurities. The sample volume is 3000ml.

[0077] experiment method:

[0078] Add phosphate buffer (pH8.0) and urea to the supernatant after 3000ml bacterial cell separation to make the final concentration respectively 50mmol / l and 1mol / l, as the protective agent in the ultrafiltration process. The supernatant liquid added with the protective agent was concentrated by ultrafiltration at a flow rate of 4000 / sec using a hollow fiber column with a molecular weight cut-off of 10KD / 30KD, and the pressure a...

Embodiment 3

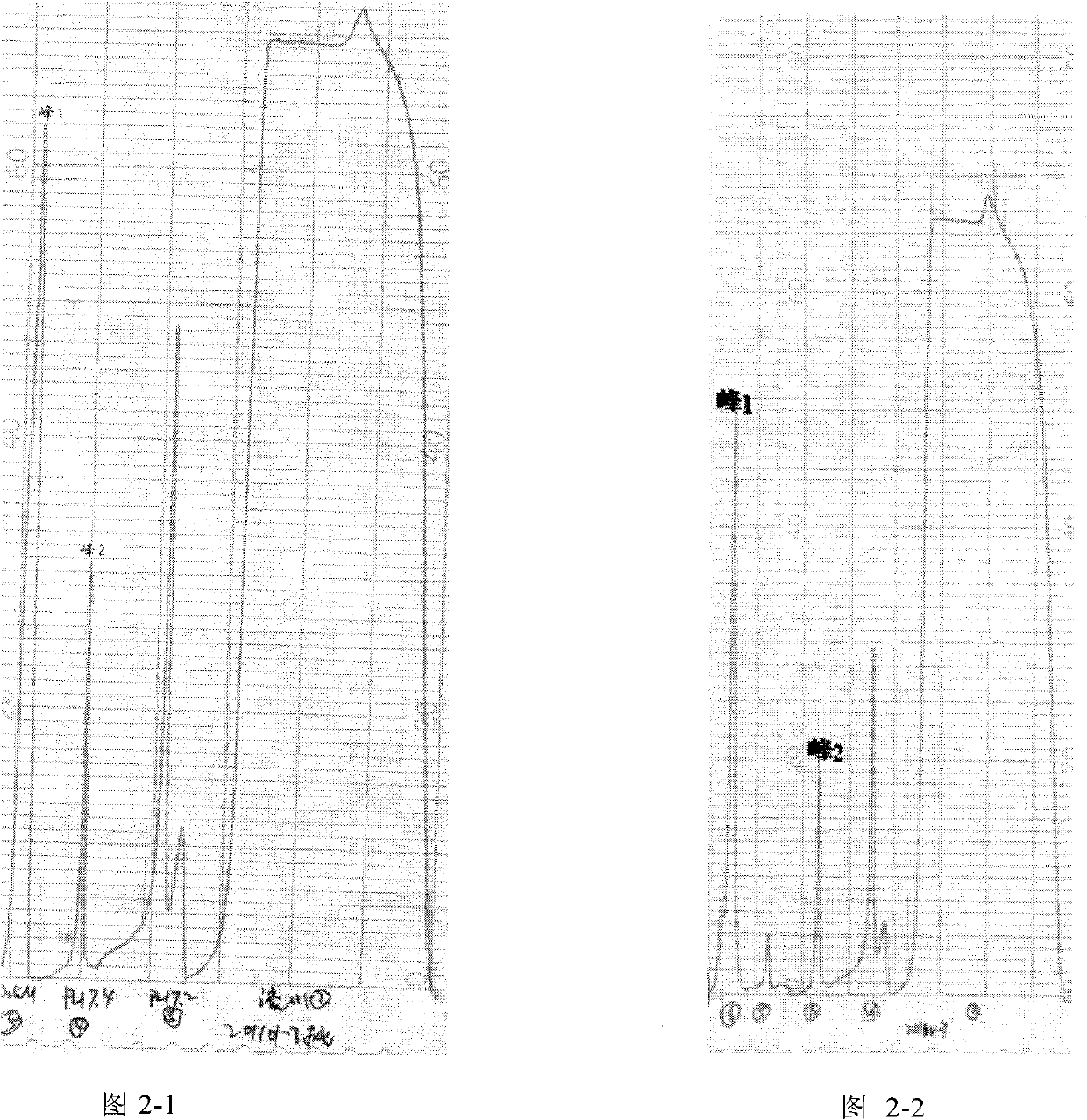

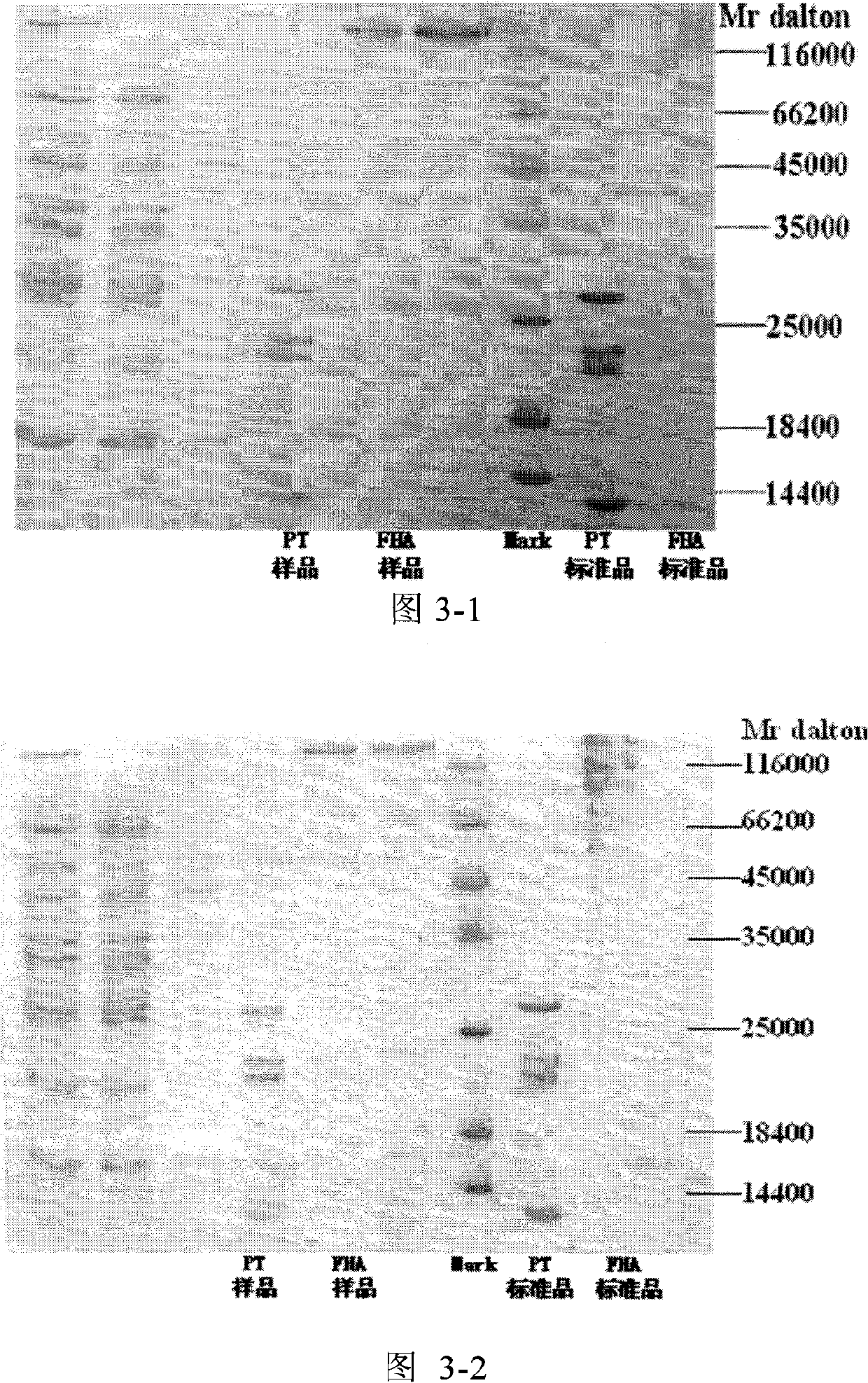

[0081] Example 3. Purification of pertussis effective antigen (1)

[0082] Test materials and samples:

[0083] Chromatographic column: XK26×20, GE

[0084] UV detector: UVD-680-1, Shanghai Jinda Biochemical Instrument Co., Ltd.

[0085] Peristaltic pump: BT-300J, Baoding Lange Constant Flow Pump Co., Ltd.

[0086] Ion exchange packing: CM-Sepharose, GE; Capto-adhere, GE

[0087] Gel filtration filler: Sephacryl S-200 High Resolution

[0088] Sample: 200ml of harvest liquid after ultrafiltration and concentration treatment

[0089] Purification of PT and FHA:

[0090] Put 60ml of CM-Sepharose medium into a 2.6×20CM chromatographic column, and equilibrate 3-5 column volumes with pH6.02M urea and 50mM phosphate buffer. Take 200ml of the supernatant obtained by ultrafiltration, pass the liquid through the chromatographic column at a flow rate of 300ml / h, monitor the protein A280 absorption value with ultraviolet light, and collect the flow-through at the same time to separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com