Denitration catalyst and preparation method thereof

A denitration catalyst and catalyst technology, applied in the field of denitration catalysts, can solve the problems of ignoring sulfur oxides, decreasing thermal efficiency, clogging catalysts, etc., and achieve the effects of wide active temperature window, low conversion rate, and reduced adsorption and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

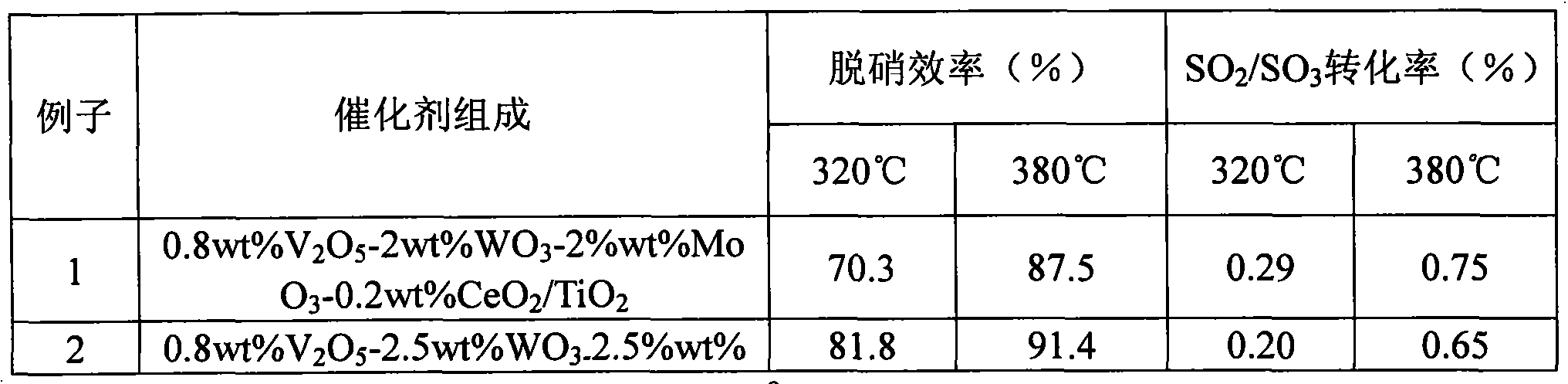

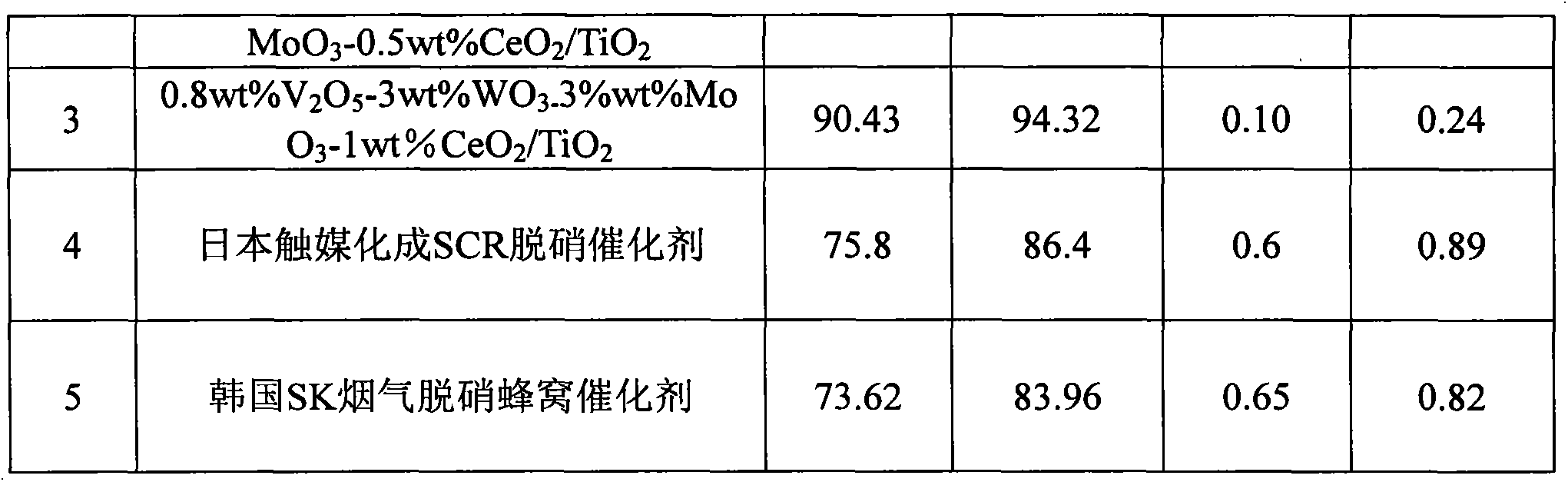

Examples

Embodiment 1

[0035] Embodiment 1: the preparation of composite catalyst

[0036] (0.8wt%V 2 O 5 -2wt% WO 3 -2wt%MoO 3 -0.2wt%CeO 2 / TiO 2 )

[0037] a) First heat 2.85kg of ionized water to 85°C, add 0.146kg of monoethanolamine and stir to dissolve, then add 0.328kg of ammonium tungstate, 0.612kg of ammonium molybdate and 0.163kg of ammonium metavanadate and stir to dissolve to make a light yellow solution .

[0038] b) 0.076 kg of cerium nitrate was dissolved in 0.060 kg of monoethanolamine solution to form a transparent solution, and then gradually added to the solution of the above step a to make a flocculent suspension.

[0039] c) Then slowly add 9.75 kg of anatase-type fine-grained titanium dioxide powder to the suspension in step b and stir while adding to make a viscous white thick slurry.

[0040] d) Add 1.95 kg of auxiliary materials and 1.8 kg of molding agent to the viscous white thick slurry obtained in step c and stir to obtain the prepared mixed...

Embodiment 2

[0045] Embodiment 2: the preparation of composite catalyst

[0046] (0.8wt%V 2 O 5 -2.5wt% WO 3 -2.5wt%MoO 3 -0.5wt%CeO 2 / TiO 2 )

[0047] a). First, heat 2.85kg of ionized water to 85°C, add 0.313kg of monoethanolamine and stir to dissolve, then add 0.36kg of ammonium tungstate, 0.765kg of ammonium molybdate and 0.163kg of ammonium metavanadate and stir to dissolve to make light yellow solution.

[0048] b). Dissolve 0.19 kg of cerium nitrate in 0.15 kg of monoethanolamine solution to form a transparent solution, then gradually add the solution in step a above to make a flocculent suspension.

[0049] c). Then slowly add 9.75 kg of anatase-type fine-grained titanium dioxide powder to the suspension in step b and stir while adding to make a viscous white thick slurry.

[0050] d). Add 1.95 kg of auxiliary materials and 1.8 kg of molding agent to the viscous white thick slurry obtained in step c and stir to obtain the prepared mixed material.

[...

Embodiment 3

[0055] Embodiment 3: the preparation of composite catalyst

[0056] (0.8wt%V 2 O 5 -3wt% WO 3 -3%wt%MoO 3 -1wt%CeO 2 / TiO 2 )

[0057] a). First heat 2.85kg of ionized water to 85°C, add 0.376kg of monoethanolamine and stir to dissolve, then add 0.492kg of ammonium tungstate, 0.918kg of ammonium molybdate and 0.163kg of ammonium metavanadate and stir to dissolve to make a light yellow solution.

[0058] b). Dissolve 0.38 kg of cerium nitrate in 0.30 kg of monoethanolamine solution to form a transparent solution, then gradually add the solution of the above step a to make a flocculent suspension.

[0059] c). Then slowly add 9.75 kg of anatase-type fine-grained titanium dioxide powder to the suspension in step b and stir while adding to make a viscous white thick slurry.

[0060] d). Then add 1.95kg of auxiliary materials and 1.8kg of molding agent to the viscous white thick slurry obtained in step c, and stir and mix to obtain the prepared mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com