A method and reaction system for simultaneously producing biogas and fatty acid

A fatty acid and biogas technology, applied in the method and its reaction system, simultaneously producing biofuels and important chemical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

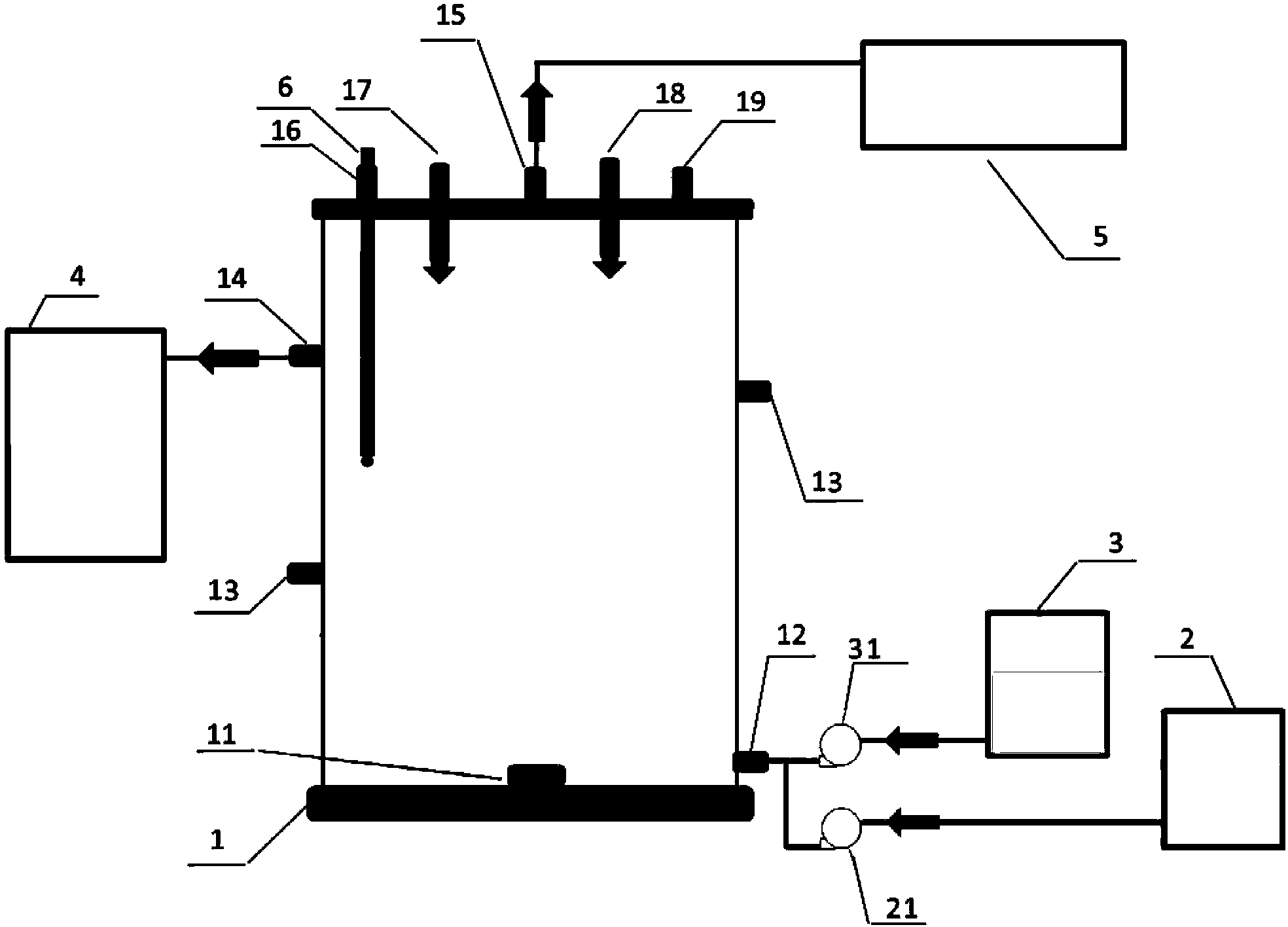

[0032] Example 1 Reaction system for simultaneous production of biogas and fatty acid

[0033] Such as figure 1 As shown, a reaction system for simultaneous production of biogas and fatty acid includes: a reactor 1, and an organic substrate supply device 2 connected to the reactor 1, a medium supply device 3, a liquid phase metabolite recovery device 4, Gas phase metabolite recovery device 5, pH value detection device 6 and pH value control device. Wherein, the reactor 1 is provided with the organic substrate supply device 2, the liquid phase metabolite recovery device 4, the gas phase metabolite recovery device 5, the pH value detection device 6, and the pH value control device 7. Water inlet 12, water outlet 14, gas outlet 15, pH meter insertion port 16, and acid liquid sample inlet 17 and lye sample inlet 18; Described culture medium supply device 3 shares with described organic substrate supply device 2 The water inlet 12.

[0034] In this embodiment, the pH value detec...

Embodiment 2

[0040] The device used adopts the device in embodiment 1, such as figure 1shown. The material of the reactor is glass. The shell has an inner diameter of 12cm and a height of 17cm. A water inlet 12, a lower sampling port 13, an upper sampling port 13 and a water outlet 14 are respectively arranged at 2 cm, 6 cm, 11 cm and 12 cm from the lower end.

[0041] The fermentation method is as follows:

[0042] Add the inoculum and medium to the anaerobic fermentation reactor. The inoculum was anaerobic sludge from the treatment of citric acid wastewater by Anhui Fengyuan Biochemical Co., Ltd., which was a mixed flora containing Thermoanaerobacter tengcongensis (high-temperature-resistant bacteria) and Methanothermobacter thermautotrophicus (high-temperature-resistant archaea). The influent of the reactor is glucose with a concentration of 10g / L, and the HRT of the reactor is 20 days. The composition of the medium is (unit: mg / L) NH 4 Cl, 500; KH 2 PO 4 , 200; Na 2 SO 4 , 40...

Embodiment 3

[0049] Example 3 In the batch mode, the reactor system for the simultaneous production of biogas and fatty acid by controlling the composition of the mixed flora through environmental conditions adopts the same reaction system as in Example 1, and adopts the same reaction system as in Example 2 from Fengyuan Biochemical Co., Ltd. Anaerobic sludge from the treatment of citric acid wastewater was used as the inoculation source. The composition of the medium is (unit: mg / L) NH 4 Cl, 500; KH 2 PO 4 , 200; Na 2 SO 4 , 40; KCl, 50; CaCl 2 , 10; MgCl 2 ·6H 2 O, 70; MnCl 2 4H 2 O, 0.8; CoCl 2 2H 2 O, 1.2; FeSO 4 ·7H 2 O, 3.2; AlCl 3 , 0.5; NaMO 4 2H2O, 0.1; H 3 BO 3 , 0.2; NiCl 2 ·6H 2 O, 0.5; CuCl 2 2H 2 O, 1.1; ZnSO 4 2H 2 O, 3.2; EDTA (Na + type), 3.0. The pH value is maintained between 6.5-7.5 and the temperature is 70°C. Run in batch mode for 10 days, add glucose three times a day, its concentration is 6.0g / L. The concentration of acetic acid reaches 35g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com