Method for removing arsenic matte by alkaline leaching at oxygen pressure and recovering arsenic

A technology of oxygen pressure alkali leaching and arsenic matte, applied in the field of hydrometallurgy, can solve the problems of arsenic secondary pollution environment, long process flow, gas pollution environment, etc., to avoid secondary pollution, fast reaction process, and automation high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

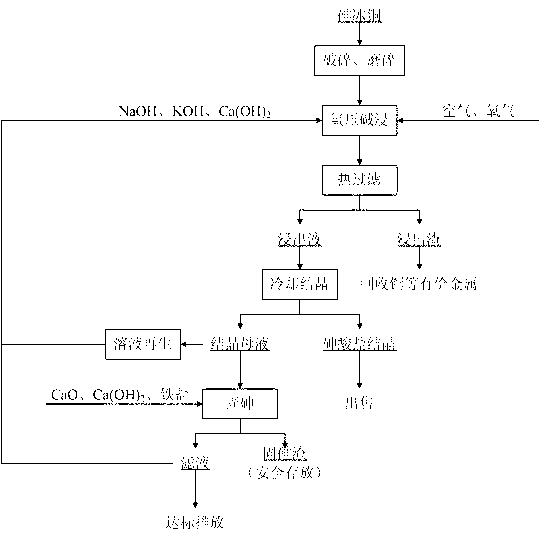

[0025] Implementation mode one: if figure 1 As shown in the process flow diagram of the method for oxygen pressure alkali leaching arsenic matte removal and recovery of arsenic,

[0026] The specific steps include the following: (1) first crush 500g of arsenic matte (the main components and mass percentages are: copper 48.5%, lead 10.23%, arsenic 22.8%) until the particle size is less than 100 mesh, and then according to the solid-liquid ratio of 1:10g / ml is added in NaOH solution to form ore slurry. The consumption of NaOH solution is 1.6 times of the theoretical consumption mass of complete reaction with arsenic and antimony in arsenic matte. The ore slurry is added in a horizontal autoclave, and the air oxidation medium is passed into, and controlled Under the conditions of pressure of 1.0MPa, leaching temperature of 150°C and stirring rate of 500r / min, the pulp was subjected to oxygen pressure alkali leaching for 2 hours; (2) the pulp after oxygen pressure alkali leaching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com