Aluminum coated steel sheet having excellent oxidation resistance and heat resistance

A technology of oxidation resistance and heat resistance, applied in hot-dip plating process, chemical instruments and methods, transportation and packaging, etc., can solve the problems of adjustment, difficult Cr concentration, etc., and achieve improved resistance characteristics, excellent adhesion, Effect of excellent high temperature strength and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] Exemplary embodiments of the present invention will be described in detail below.

Embodiment

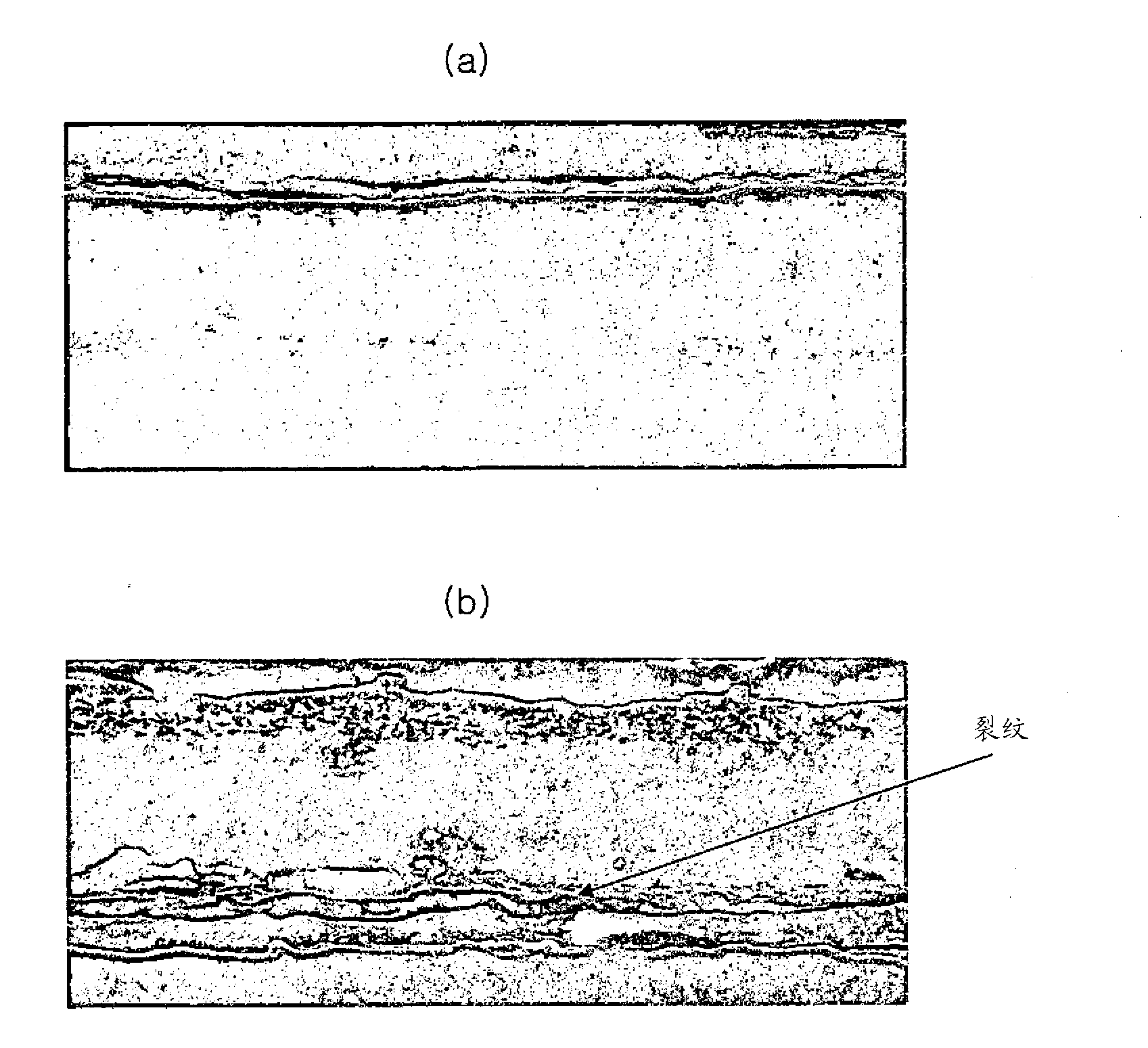

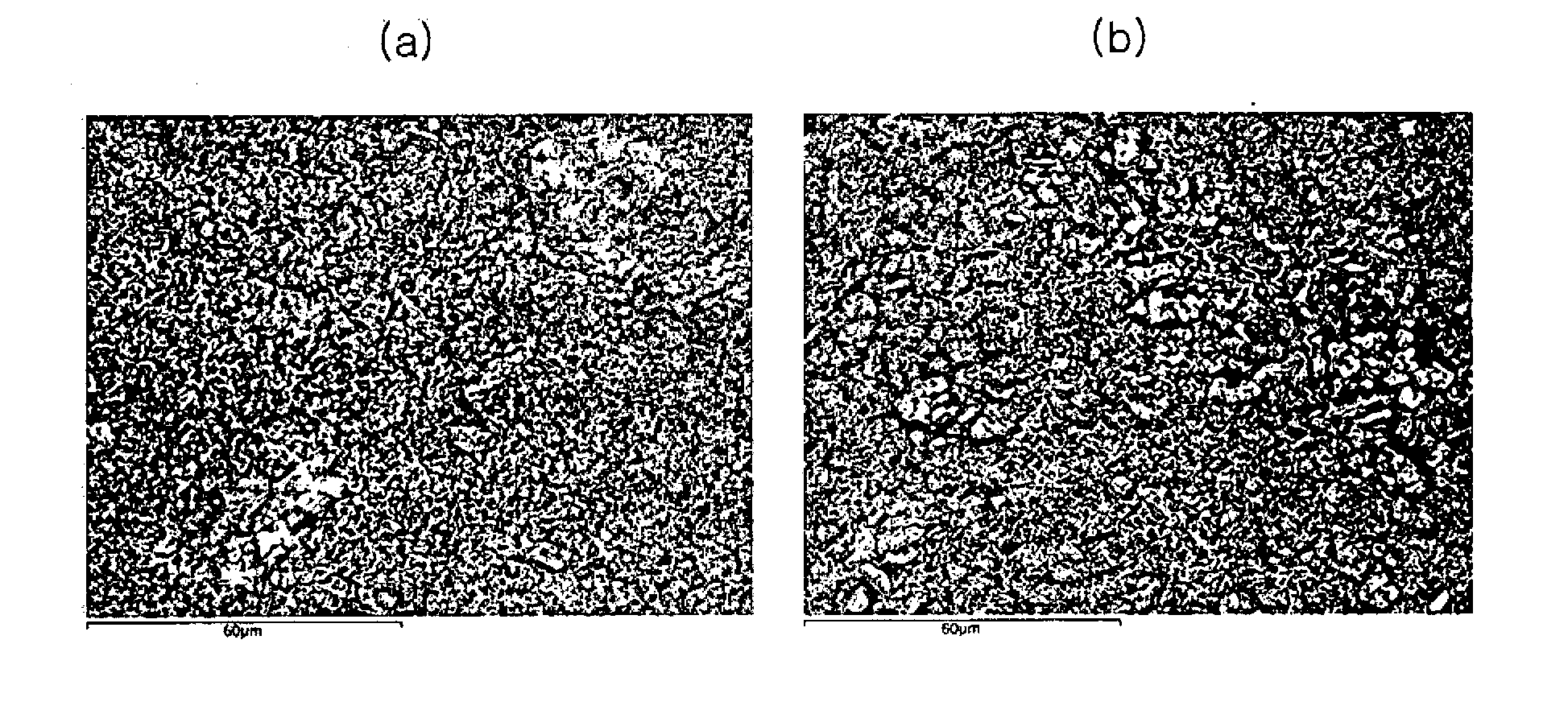

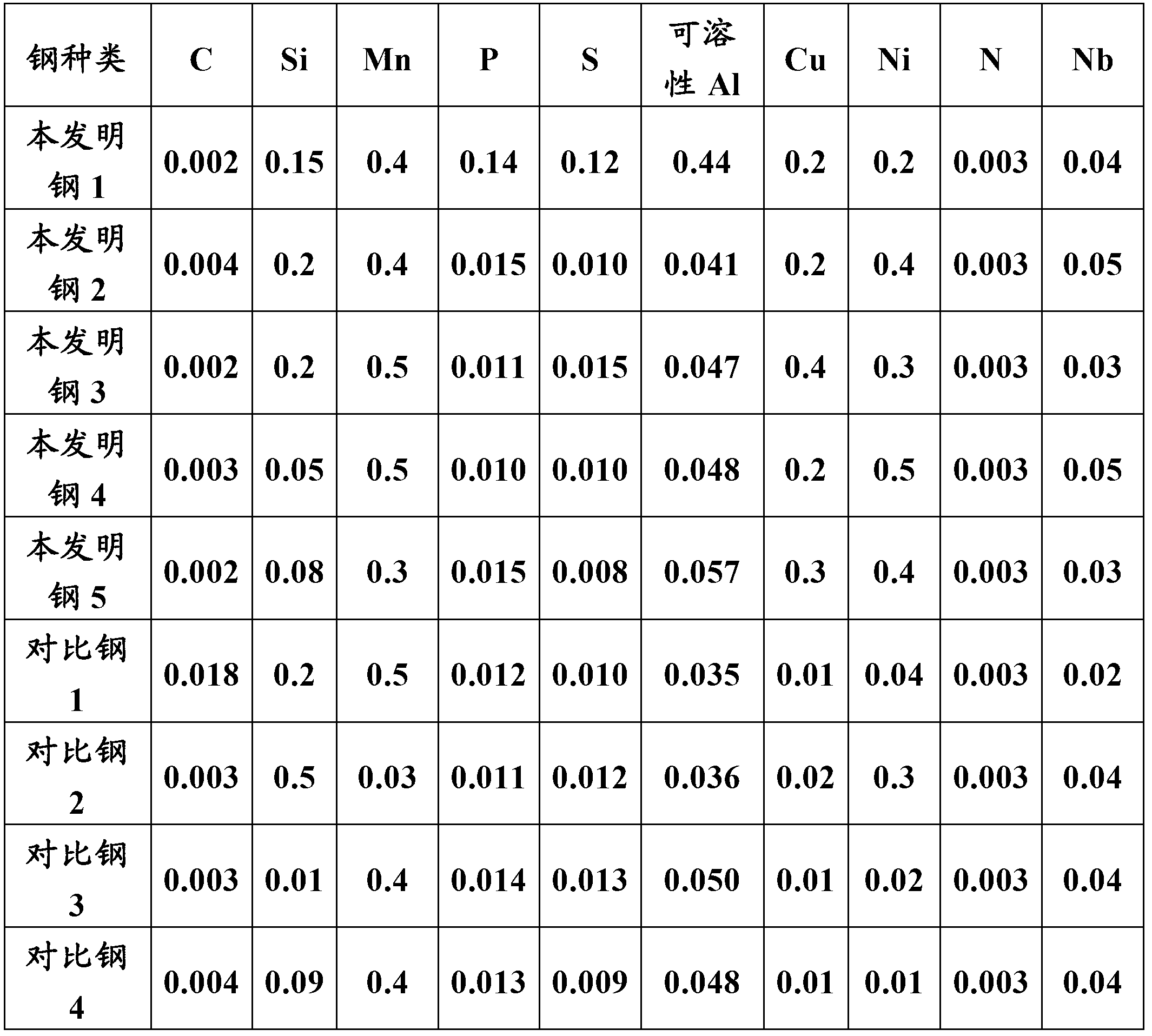

[0043] Steel sheets having the compositions shown in Table 1 were vacuum melted and heated in a heating furnace at 1150°C to 1250°C for 1 hour, followed by hot rolling. Hot rolling is completed at 890°C to 920°C. Coiling was performed at 700°C. Then, the hot-rolled steel sheet was pickled and cold-rolled at a cold rolling reduction of 75%, and then, the cold-rolled steel sheet was hot-dipped aluminized.

[0044] For hot-dip aluminizing, degreasing cold-rolled steel sheets are heat treated in a reducing atmosphere of nitrogen and hydrogen (30% hydrogen concentration) at a dew point of -40°C and the maximum reduction annealing heat treatment temperature is 820°C. After heat treatment, the steel plate is cooled to 680°C and soaked for a period of time, and then immersed in a coating tank kept at 680°C for coating.

[0045] The plating bath consisted of 8.5% by weight Si and the balance aluminum. Gas wiping is performed to ensure a coating thickness of 20 to 30 μm per side. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com