Method for removing aerosol in ammonia washing desulphurization of flue gas

An aerosol and flue gas technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as aerosol emissions, and achieve the effects of reducing corrosion, improving the ecological environment, and improving the living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

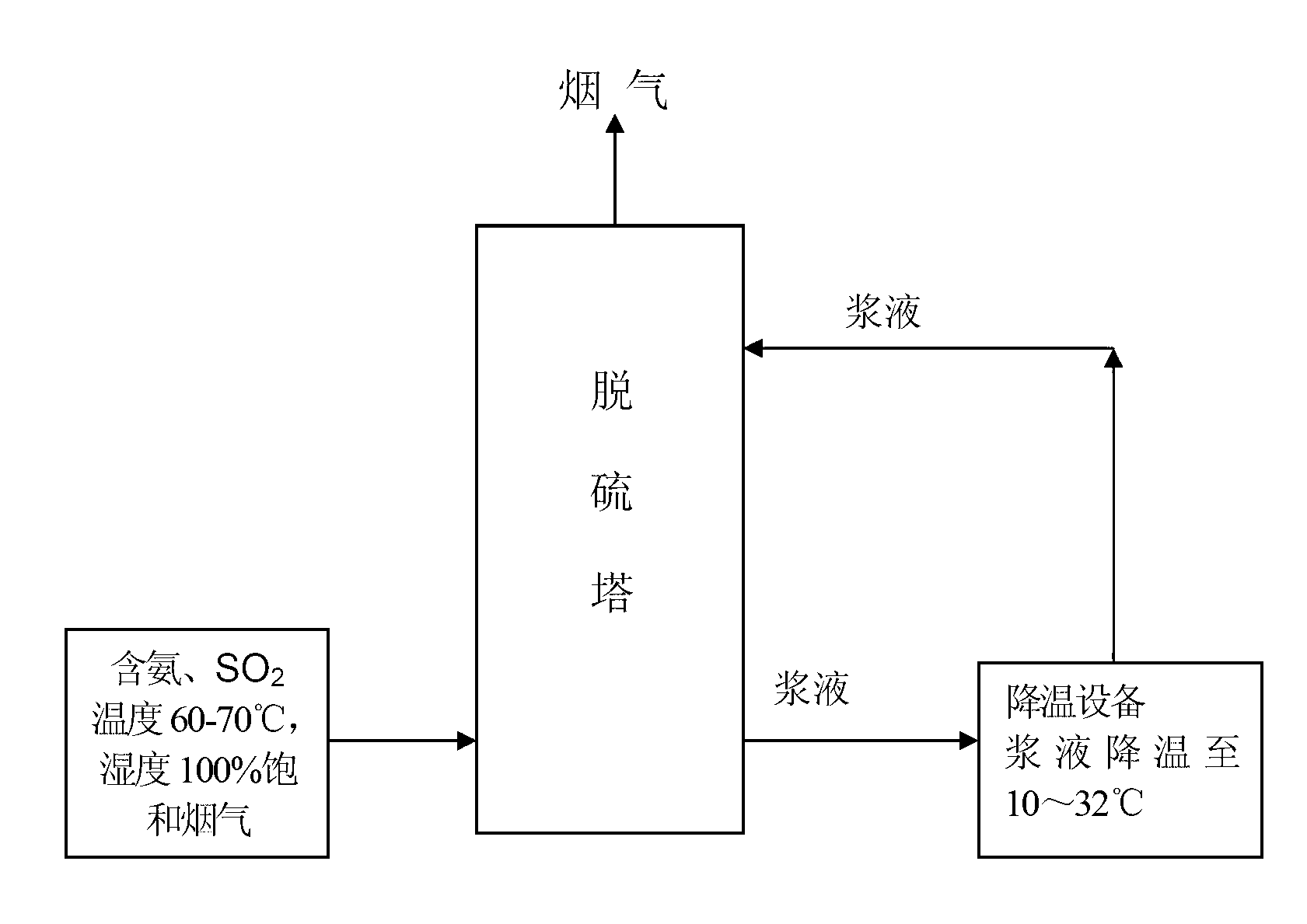

[0011] Process flow chart of the present invention is attached figure 1 , the technical process of the present invention is as follows:

[0012] The spray slurry in the desulfurization section of the desulfurization tower entrains ammonia and SO at the same time as the gas-liquid ratio of 1:3-15 cubic meters per liter and the temperature of 60--70°C and humidity of 100% from the previous process. 2 The saturated flue gas is contacted in countercurrent, heat exchange and chemical reaction are realized simultaneously during the contact process, the temperature of the slurry rises by 5-16°C, and the temperature of the flue gas decreases at the same time. After the slurry falls into the bottom of the desulfurization tower, it is pumped from the bottom into the cooling tower where the slurry is cooled by using the residual pressure. The slurry exchanges heat with the natural air, so that the temperature of the slurry is reduced to a range close to the outdoor air temperature ± 3 °C...

Embodiment 2

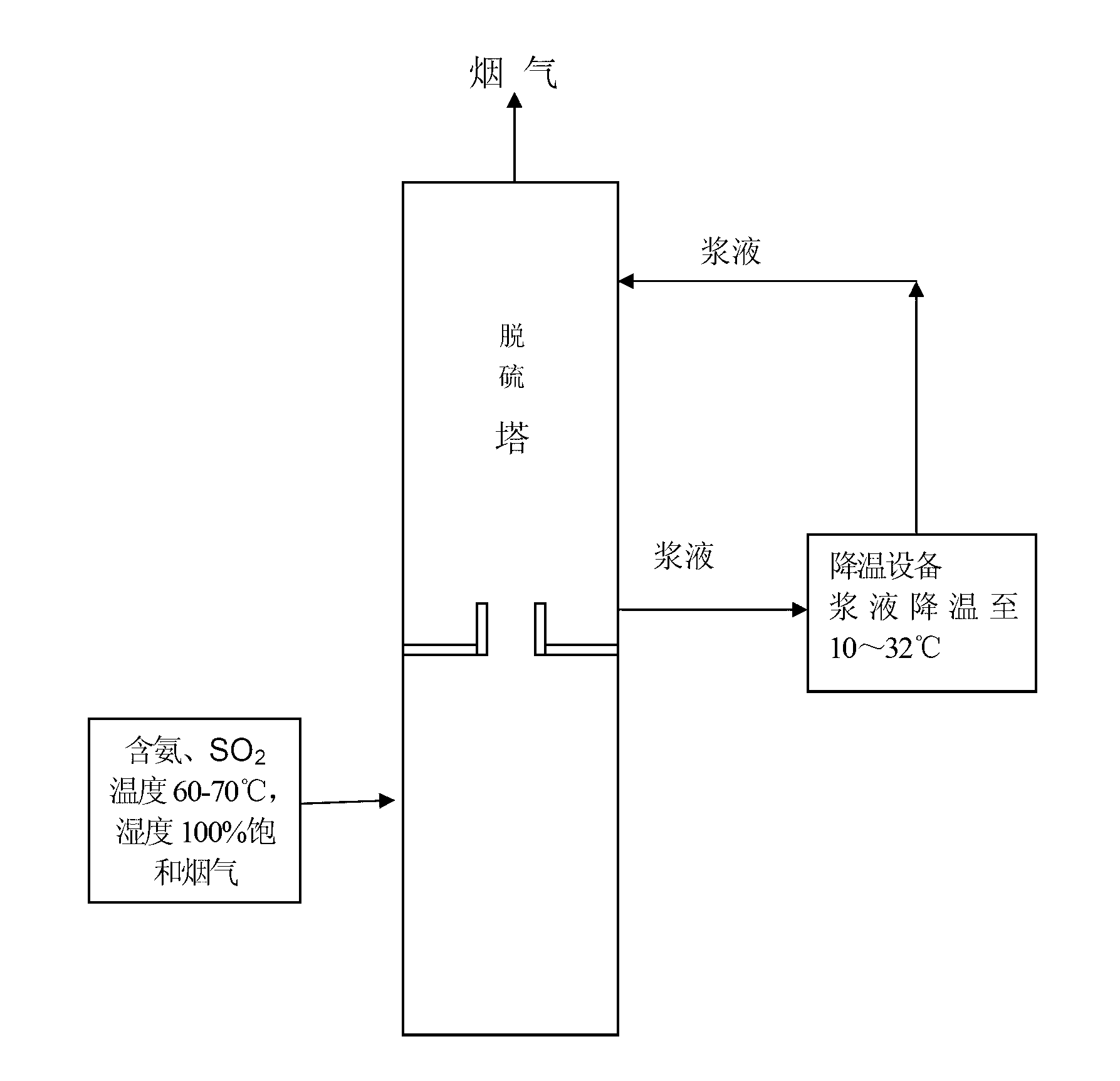

[0014] Process flow of the present invention is attached figure 2 , the technical process of the present invention is as follows:

[0015] In the washing section of the desulfurization tower, the spray slurry is mixed with a gas-liquid ratio of 1:3-15 cubic meters per liter and a temperature of 60--70°C, a humidity of 100%, entrained ammonia, SO 2 The saturated flue gas is contacted in countercurrent, and heat exchange and chemical reaction are realized during the contact process. After the slurry falls into the bottom of the washing section, it is driven from the bottom into a cooling tower for cooling the slurry with a pump or residual pressure. The slurry exchanges heat with the natural air, so that the temperature of the slurry is reduced to a range close to the outdoor air temperature ± 3°C. The temperature is 10-32°C, and then the lift pump is used to drive the spray nozzle into the tower to contact with the flue gas countercurrently to reduce the temperature of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com