Hydroxyapatite/chitosan composite coating and preparation method thereof

A hydroxyapatite and composite coating technology, applied in coating, medical science, prosthesis, etc., can solve the problems of falling off, peeling, weak strength, etc., to improve the bonding force, promote rapid formation, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

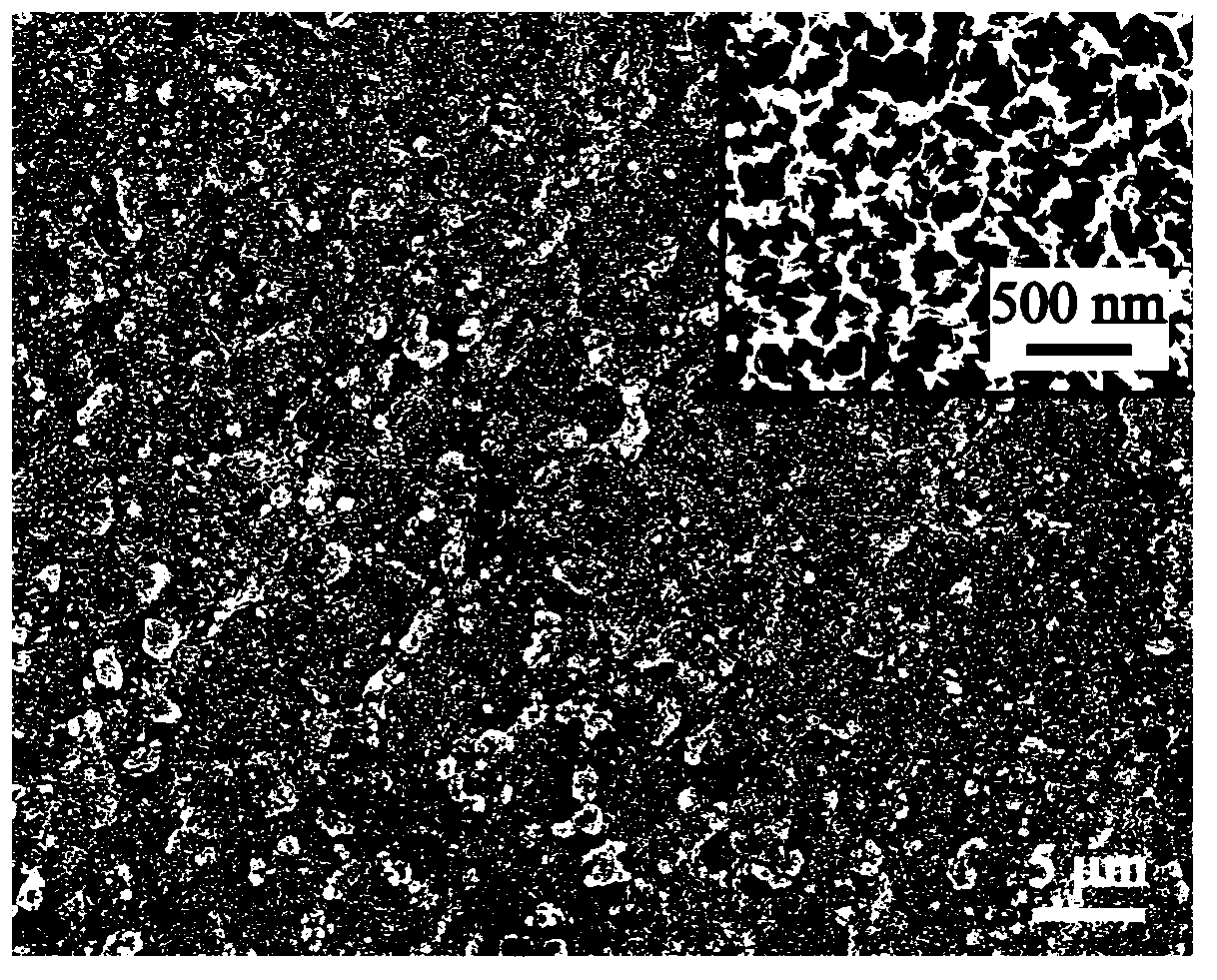

Embodiment 1

[0031] Step 1: Pretreatment of biomedical metal substrates

[0032] (1) Using Ti6Al4V titanium alloy as the metal matrix, cut it into small blocks of 12mm×12mm×0.9mm.

[0033] (2) Polish with SiC sandpaper and ultrasonically clean with acetone and deionized water for 20 min each; then in 1.0M H 3 PO 4 Soak in -2wt.% HF solution for 5 minutes to form a TiOx layer on the surface of the titanium alloy; after acid treatment, clean it with deionized water and then ultrasonic cleaning with absolute ethanol.

[0034] (3) Dry at 60°C for use.

[0035] Step 2: Prepare a solution containing chitosan, calcium ions and phosphate ions

[0036] (1) Measure 10ml of glacial acetic acid and dilute to 500ml to obtain a 2vt.% dilute acetic acid solution.

[0037] (2) Take 100ml of 2vt.% glacial acetic acid solution, add 1.0g of chitosan, stir continuously to dissolve until clear and transparent.

[0038] (3) Weigh 2.3615g Ca(NO 3 ) 2 4H 2 O with 0.9342g NaH 2 PO 4 2H 2 A solution of O d...

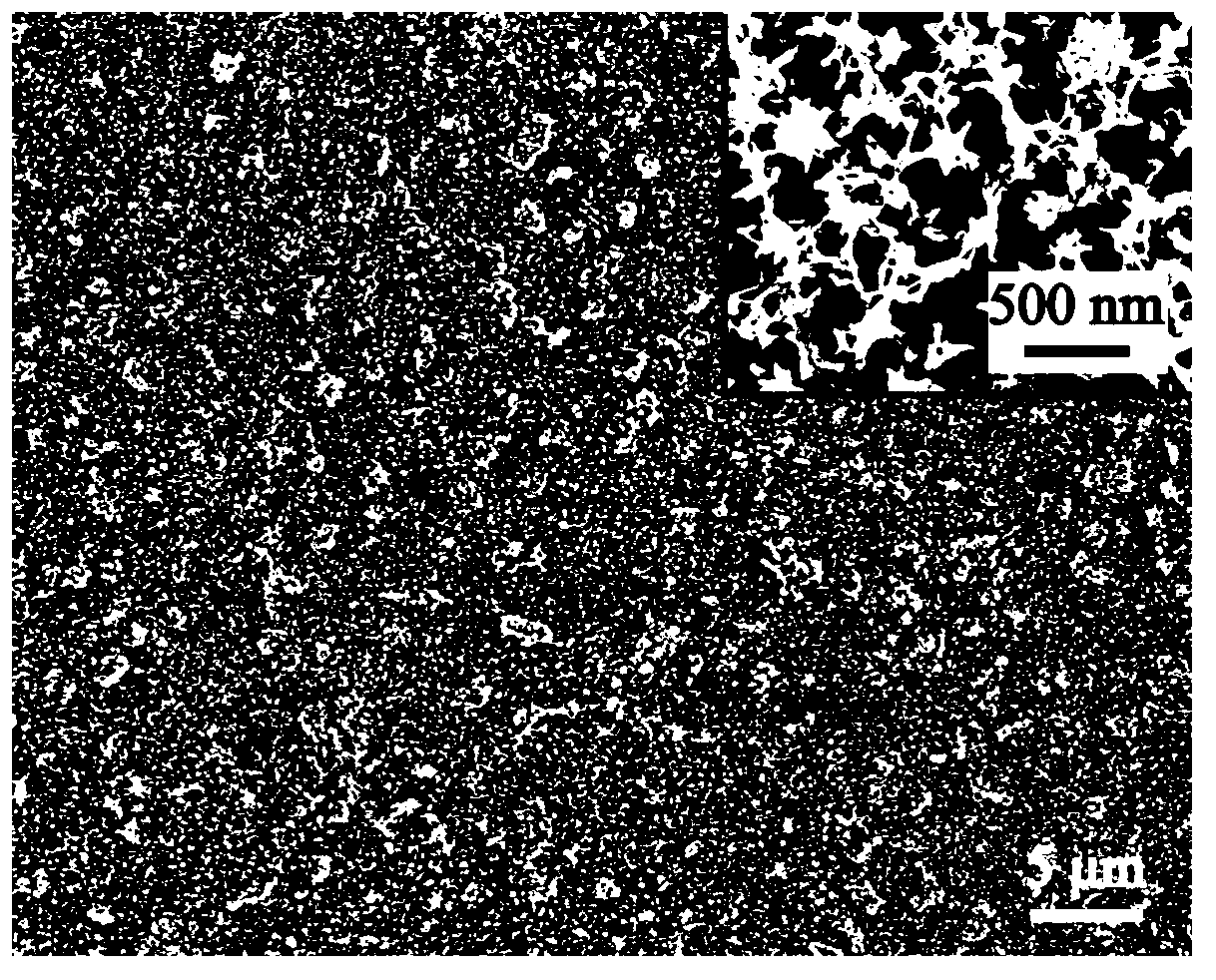

Embodiment 2

[0047] Step 1: Pretreatment of biomedical metal substrates

[0048] (1) Using Ti6Al4V titanium alloy as the metal matrix, cut it into small blocks of 12mm×12mm×0.9mm.

[0049] (2) Polish with SiC sandpaper and ultrasonically clean with acetone and deionized water for 20 min each; then in 1.0M H 3 PO 4 Soak in -2wt.% HF solution for 5 minutes to form a TiOx layer on the surface of the titanium alloy; after acid treatment, clean it with deionized water and then ultrasonic cleaning with absolute ethanol.

[0050] (3) Dry at 60°C for use.

[0051] Step 2: Prepare a solution containing chitosan, calcium ions and phosphate ions

[0052] (1) Measure 20ml of glacial acetic acid and dilute to 500ml to obtain a 4vt.% dilute acetic acid solution.

[0053] (2) Take 100ml of 4vt.% glacial acetic acid solution, add 1.0g of chitosan, stir continuously to dissolve until clear and transparent.

[0054] (3) According to the molar ratio of calcium and phosphorus of 2:1, weigh 1.5614g CaF 2...

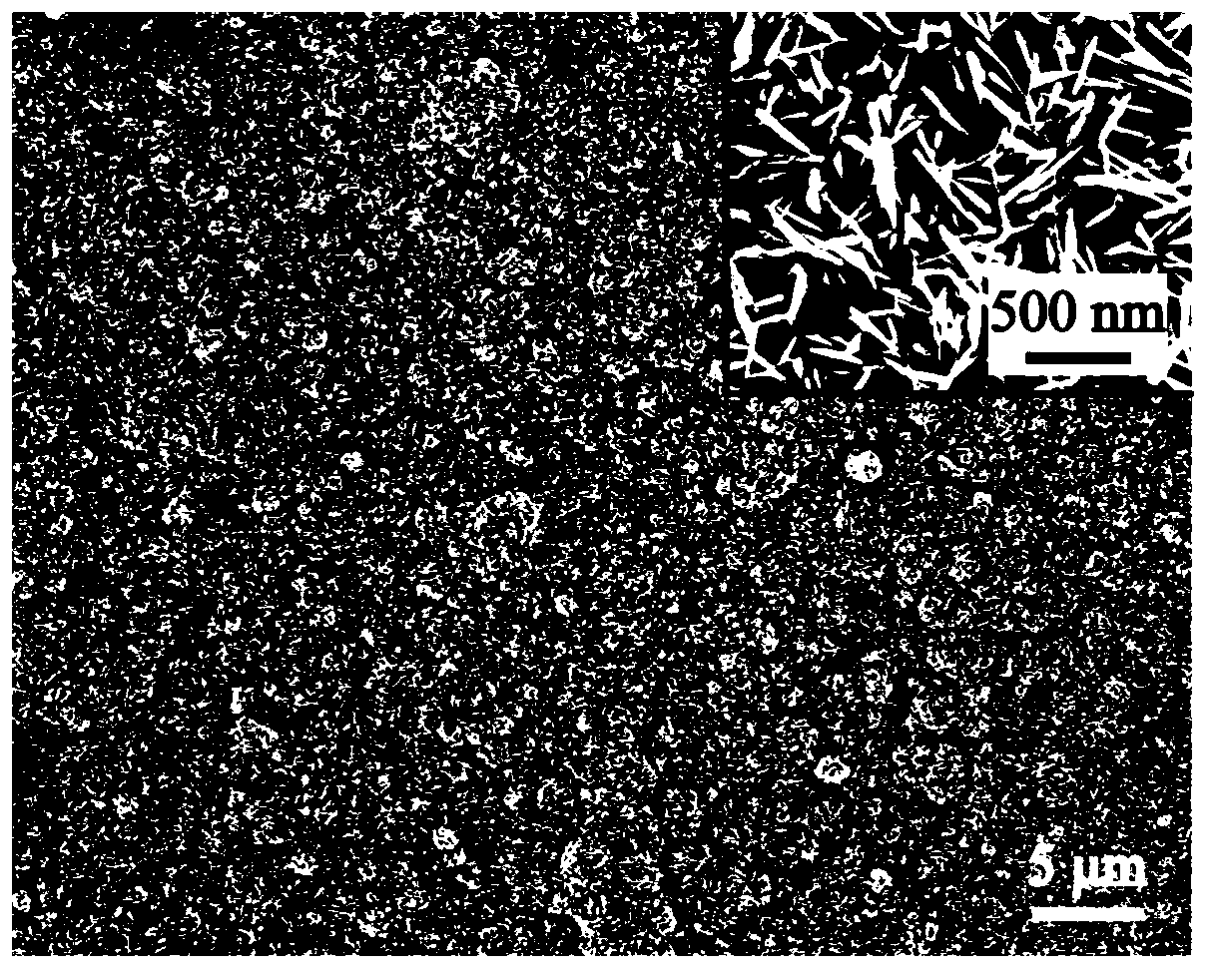

Embodiment 3

[0063] Step 1: Pretreatment of biomedical metal substrates

[0064] (1) Using Ti6Al4V titanium alloy as the metal matrix, cut it into small blocks of 12mm×12mm×0.9mm.

[0065] (2) Polish with SiC sandpaper and ultrasonically clean with acetone and deionized water for 20 min each; then in 1.0M H 3 PO 4 Soak in -2wt.% HF solution for 5 minutes to form a TiOx layer on the surface of the titanium alloy; after acid treatment, clean it with deionized water and then ultrasonic cleaning with absolute ethanol.

[0066] (3) Dry at 60°C for use.

[0067] Step 2: Prepare a solution containing chitosan, calcium ions and phosphate ions

[0068] (1) Measure 10ml of glacial acetic acid and dilute to 500ml to obtain a 2vt.% dilute acetic acid solution.

[0069] (2) Take 100ml of 2vt.% glacial acetic acid solution, add 1.0g of chitosan, stir continuously to dissolve until clear and transparent.

[0070] (3) Weigh 2.3615g Ca(NO 3 ) 2 4H 2 O with 0.9342g NaH 2 PO 4 2H 2 A solution of O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com