Halogen-free flame retardant polystyrene nano composite material and preparation method thereof

A technology of polystyrene nano and composite materials, which is applied in the field of polymer flame retardant, can solve the problems of poor compatibility and easy agglomeration of nanosheets, and achieve high flame retardant efficiency, excellent flame retardant smoke suppression performance, additive Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A halogen-free flame-retardant polystyrene nanocomposite material, comprising the following components (in parts by mass):

[0034] General-purpose polystyrene resin (PG-383, purchased from Taiwan Chi Mei Industrial Co., Ltd.): 90 parts;

[0035]Magnesium-aluminum layered double hydroxide (see Yoshioka T, Uchda M, Okuwaki A. Hydrotalcite synthesis using calculated dolomite as a magnesium and alkali resource. Journal of Material Science Letters, 2002, 21:1747-1749. for the preparation method): 5 share;

[0036] Octakis(dibromoethyl) POSS (Octakis(dibromoethyl) POSS, HA0640) (purchased from Hybrid Plastics, USA): 0.5 parts;

[0037] SEBS (purchased from Nanjing Jintian Plastic Co., Ltd.): 2 copies;

[0038] Antioxidant 1010 (purchased from Yixing Angel Synthetic Chemical Co., Ltd.): 0.5 parts;

[0039] Zinc stearate (purchased from Shanghai Chuangzhen Chemical Co., Ltd.): 1 part;

[0040] Titanate coupling agent NXT201 (purchased from Nanjing Xuyang Chemical Co., Ltd....

Embodiment 2

[0047] Embodiment 2. A halogen-free flame-retardant polystyrene nanocomposite material, the difference from Example 1 is that the components are modified as follows: general-purpose polystyrene resin: 88 parts, zinc-aluminum layered double hydroxide: 5 parts, octaphenyl POSS (octaphenyl POSS, MS0840): 0.1 parts, EPDM: 5 parts, antioxidant 168: 0.8 parts, butyl stearate: 0.3 parts, titanate coupling agent NXT201: 0.8 parts.

[0048] The temperature setting of the twin-screw extruder in step (3) is as shown in Table 2 (unit: °C)

[0049] Table 2

[0050] a district Second District Third District Four districts five districts nose 165 185 190 185 180 180

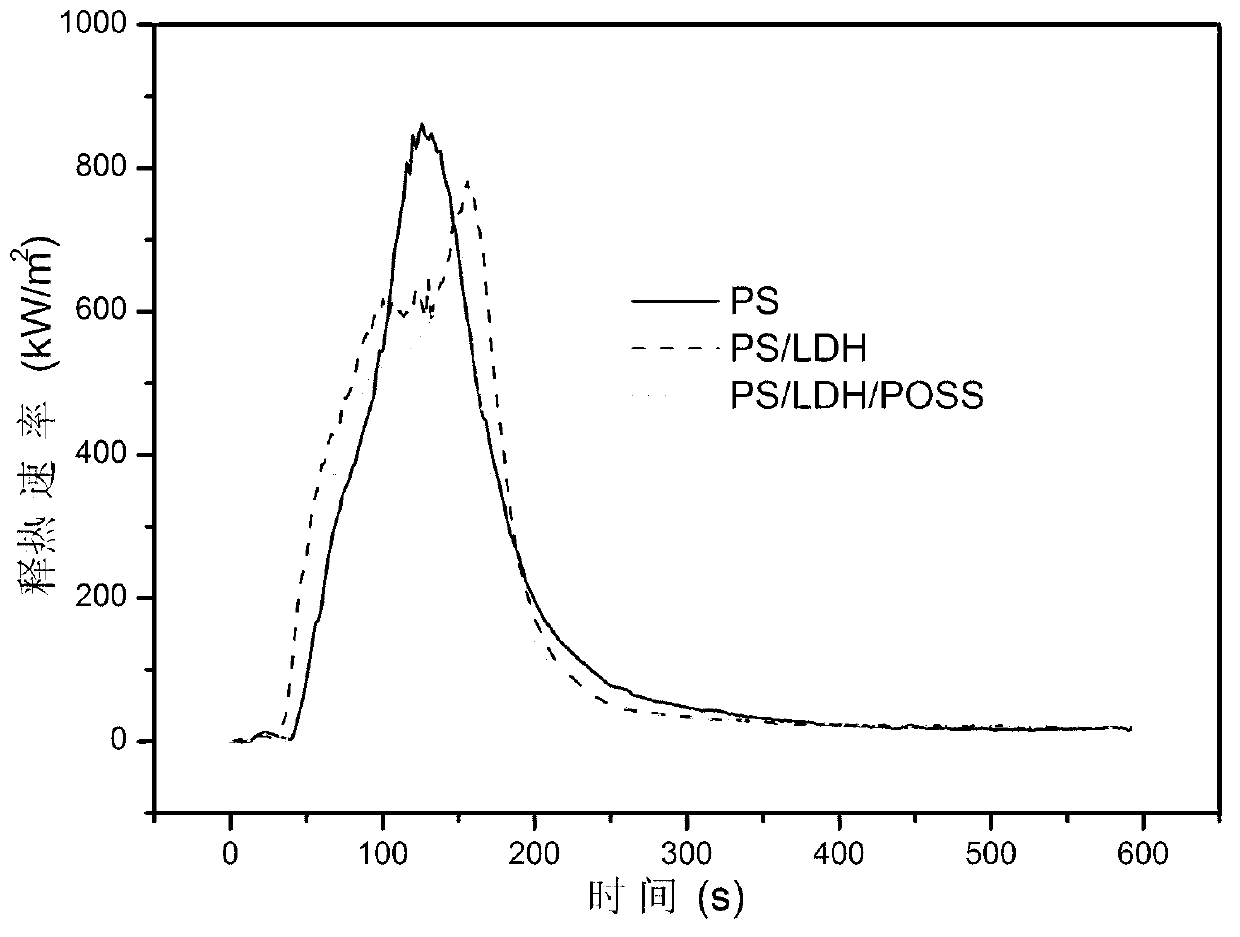

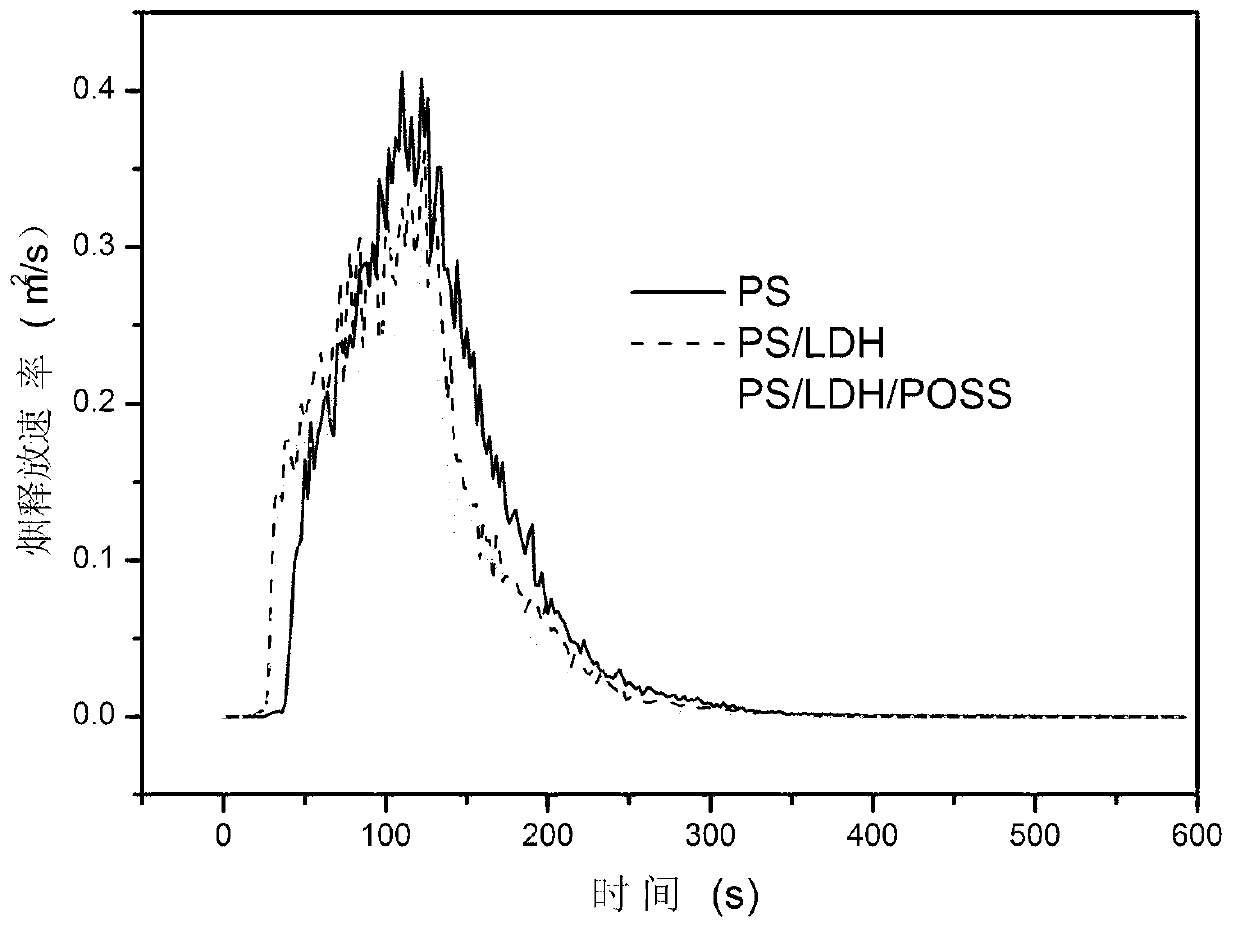

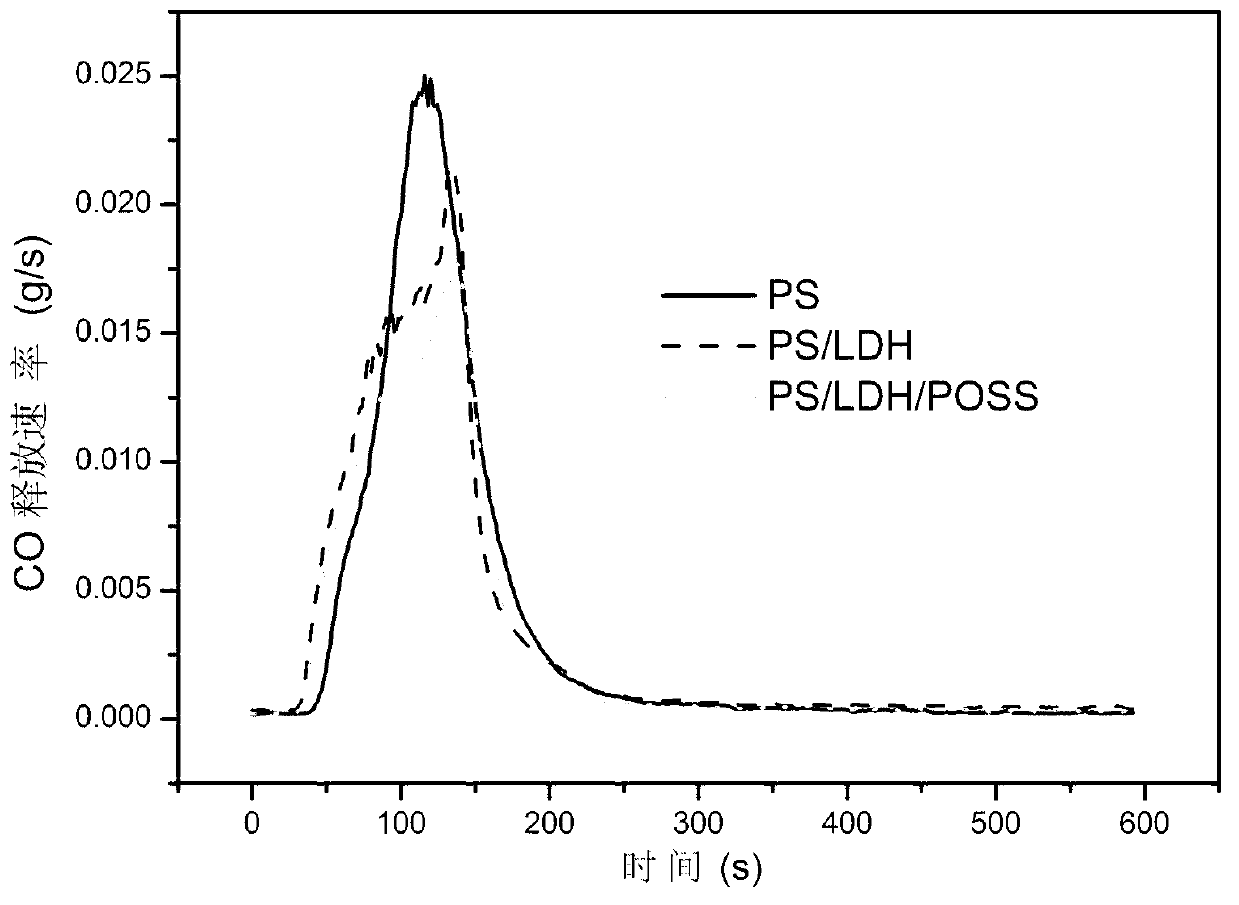

[0051] The resulting nanocomposite has a pHRR of 625kW / m 2 , compared to pure PS (865 kW / m 2 ) decreased by 28%, and the total smoke emission was 3885.2m 2 / m 2 , than pure PS (4498.8m 2 / m 2 ) decreased by 14%, and the average CO production was 0.053 g / g, which was 0.012 g / g lower than ...

Embodiment 3

[0053] A halogen-free flame-retardant polystyrene nanocomposite material, the difference from Example 1 is that the components are modified as follows: general-purpose polystyrene resin: 77 parts, cobalt-aluminum layered double hydroxide: 15 parts, glycidyl POSS Cage mixture (glycidyl POSS cage mixture, EP0409): 1 part, EPDM: 5 parts, antioxidant 168: 1 part, butyl stearate: 0.5 part, titanate coupling agent NXT201: 0.5 part.

[0054] The resulting nanocomposite has a pHRR of 556kW / m 2 , compared to pure PS (865 kW / m 2 ) decreased by 36%, and the total smoke emission was 3652.2m 2 / m 2 , than pure PS (4498.8m 2 / m 2 ) decreased by 19%, and the average CO production was 0.049 g / g, which was 0.016 g / g lower than that of pure PS (0.065 g / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com