Beta-galactosidase with broadened nucleoside substrate specificity

A galactosidase and specific technology, applied in the field of enzyme protein engineering, can solve the problems of difficult glycosylation modification and low nucleophilicity of phenyl ring hydroxyl group.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

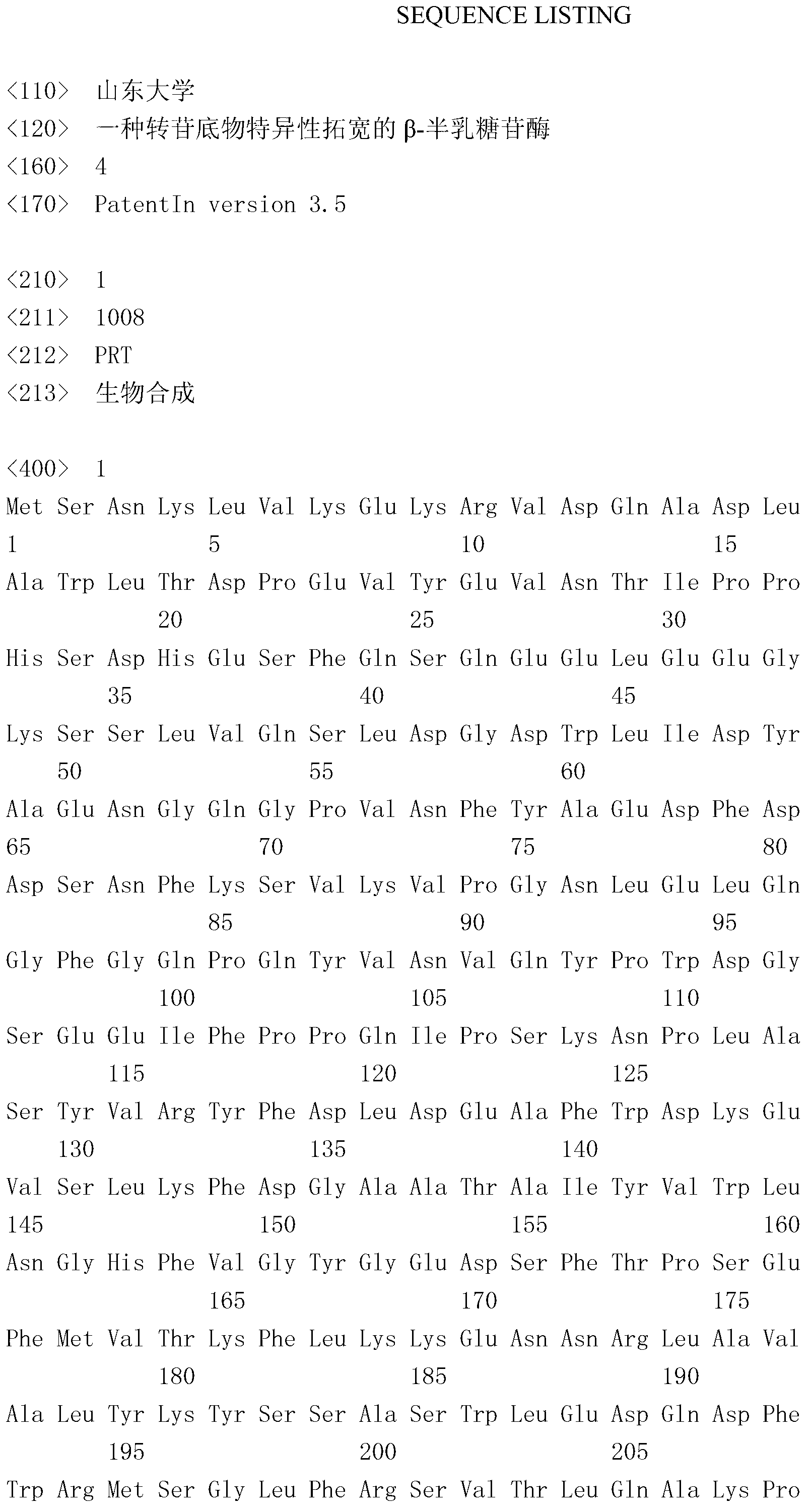

[0035] Example 1: Acquisition of the gene of β-galactosidase with broadened substrate specificity and preparation of enzyme protein

[0036] Artificially synthesized β-galactosidase gene sequence with GenBank accession number EU734748.1 (encoded protein GenBank accession number is ACE06986.1), ligated it to pET-21b(+) plasmid, and transformed Escherichia coli BL21(DE3) , and then extract the recombinant plasmid, use the plasmid as a template, and introduce a mutation into the enzyme gene sequence by PCR using a mutation kit (Quanjin Easy Mutagenesis System, Beijing);

[0037] The upstream primer is: 5′-CGGGGATGACTCC TTT GGGCAGAAGGTCCA-3'; SEQ ID NO.3

[0038] The downstream primer is: 5′- AAA GGAGTCATCCCCGCCGACCCCCCATCTG-3'; SEQ ID NO.4

[0039] In the primer, TTT encodes phenylalanine, and tryptophan at position 980 is replaced by phenylalanine by PCR;

[0040] PCR amplification conditions were: pre-denaturation at 95°C for 5 minutes; 20 cycles of reaction (denaturation...

Embodiment 2

[0043] Example 2: Synthesis of caffeic acid galactoside using mutant β-galactosidase

[0044] 50 mL of the reaction system was prepared with pH 7.0, 50 mM potassium phosphate buffer solution, the final concentration of lactose was 0.2 M, the final concentration of caffeic acid was 0.1 M, and the amount of enzyme added was 4 μg / mL. After reacting at 45°C for 45 minutes, boil at 100°C for 5 minutes to terminate the reaction.

[0045]Centrifuge the boiled reaction solution at 12,000 rpm for 20 minutes, absorb 1 mL of the supernatant, and separate it with a Bio-gel P2 chromatographic column with a size of 15 mm×100 cm. Use water as the mobile phase and a flow rate of 0.2 mL / min to collect the eluted samples. , thin-layer chromatography detection, combined products with the same migration distance, freeze-dried and made into powder, which is the glycoside product;

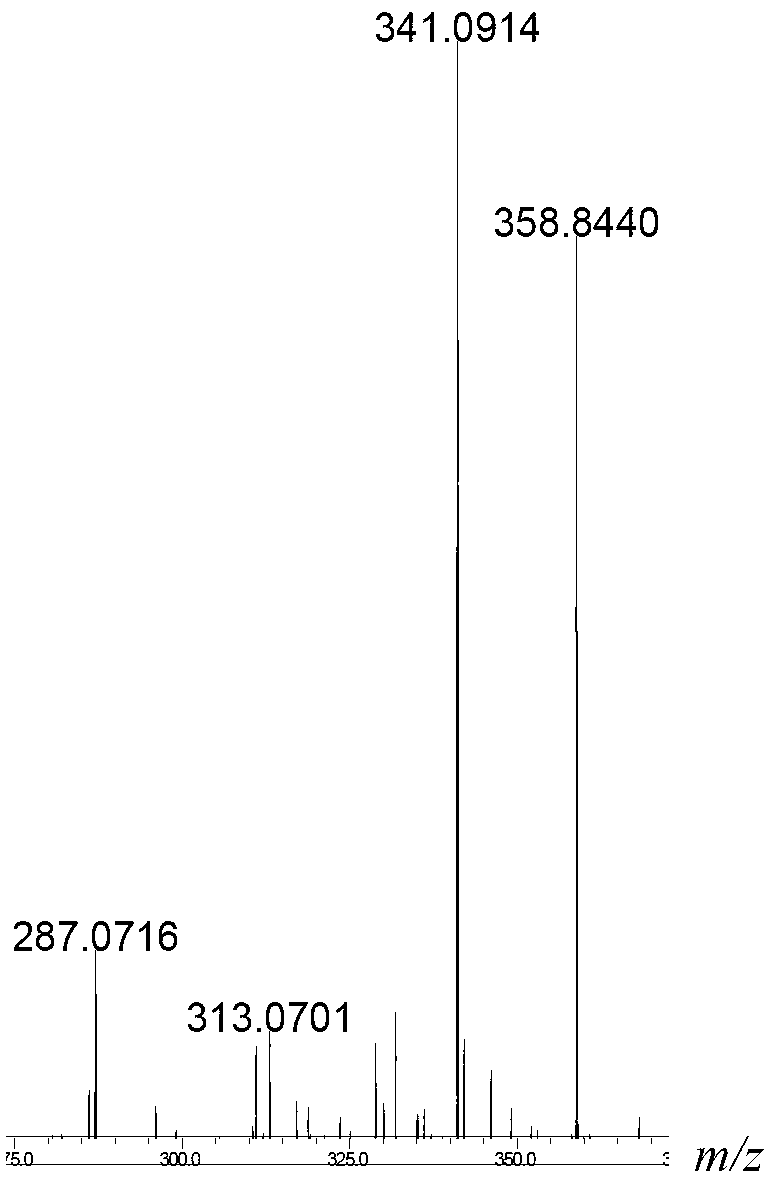

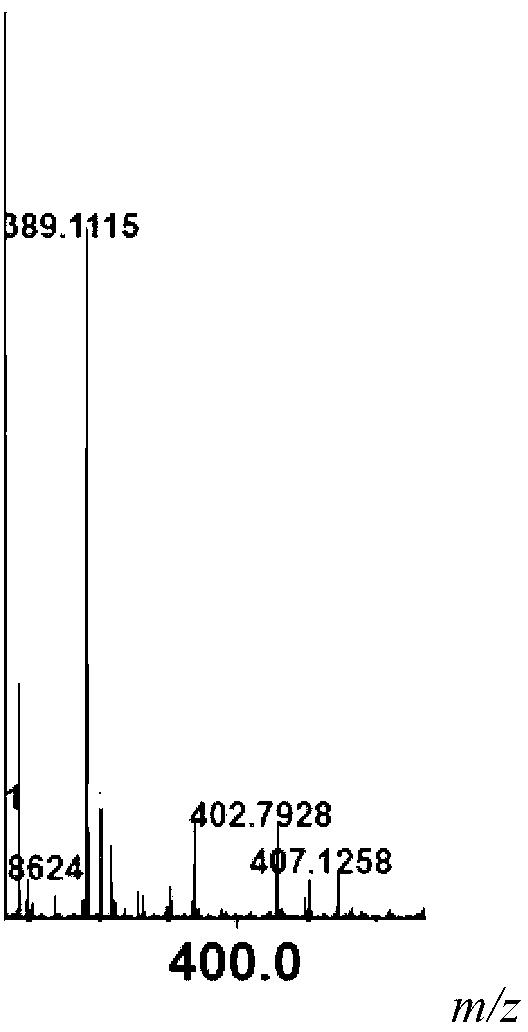

[0046] Take the above glycoside product and dilute it with water to a solution with a mass percentage of 1%, and per...

Embodiment 3

[0050] Example 3: Synthesis of resveratrol galactoside using mutant β-galactosidase

[0051] The final concentration of the lactose solution prepared with phosphate buffer is 0.2M, the final concentration of resveratrol prepared with acetone is 0.05M, and the amount of β-galactosidase whose amino acid sequence is shown in SEQ ID NO.1 is 10 μg. / mL, react in a water bath at 40°C for 20 minutes, and boil to terminate the reaction.

[0052] The boiled reaction solution was centrifuged at 12,000 rpm for 20 minutes, the supernatant was sucked, and the sample was spread on a preparative thin-layer chromatography plate (PLC Silica gel60F254, Merck). After the development, take a 1cm-wide strip plate every 10cm on the chromatographic plate for color development, and determine the position of the target sugar on the thin-layer chromatographic plate. Then scrape off the silica gel powder containing the target glycoside in the non-colored area of the thin-layer chromatography plate, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com