A kind of preparation method of p-type dye-sensitized battery

A dye-sensitized cell, p-type technology, applied in the field of material preparation and solar cells, can solve the problems of small short-circuit current, reduced charge separation efficiency, low efficiency of pn-type DSCs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

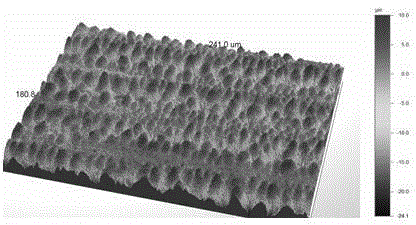

[0023] 1. Using femtosecond laser to form fine and dense micro-nano structures on nickel sheets

[0024] The laser output center wavelength is 808 nm, the pulse width is 45 femtoseconds, and the repetition is 1 kHz.

[0025] On the XY plane of the computer-controlled three-dimensional precision mobile platform, the laser is focused on the nickel sheet. After the beam is focused, the spot diameter is 80 microns. The computer controls the sample stage to move from left to right along the X direction. After one line is scanned, it moves up along the Y direction. 40 microns, and then scan from right to left; repeat this process, the scanning area is 2cm×2cm, the femtosecond laser power is 500mW, and the scanning rate is 1.5mm / min; 12 microns with an interval of 8 microns.

[0026] 2. Form a 600nm thick NiO layer on the nickel sheet by thermal oxidation

[0027] Put the nickel sheet with micro-nano structure on the surface into the heating furnace, heat in the oxygen atmosphere, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com