Method for producing junction field effect transistor

A field-effect transistor and manufacturing method technology, which is applied to the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc. The effect of illuminating the effect ability and reducing the additional cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

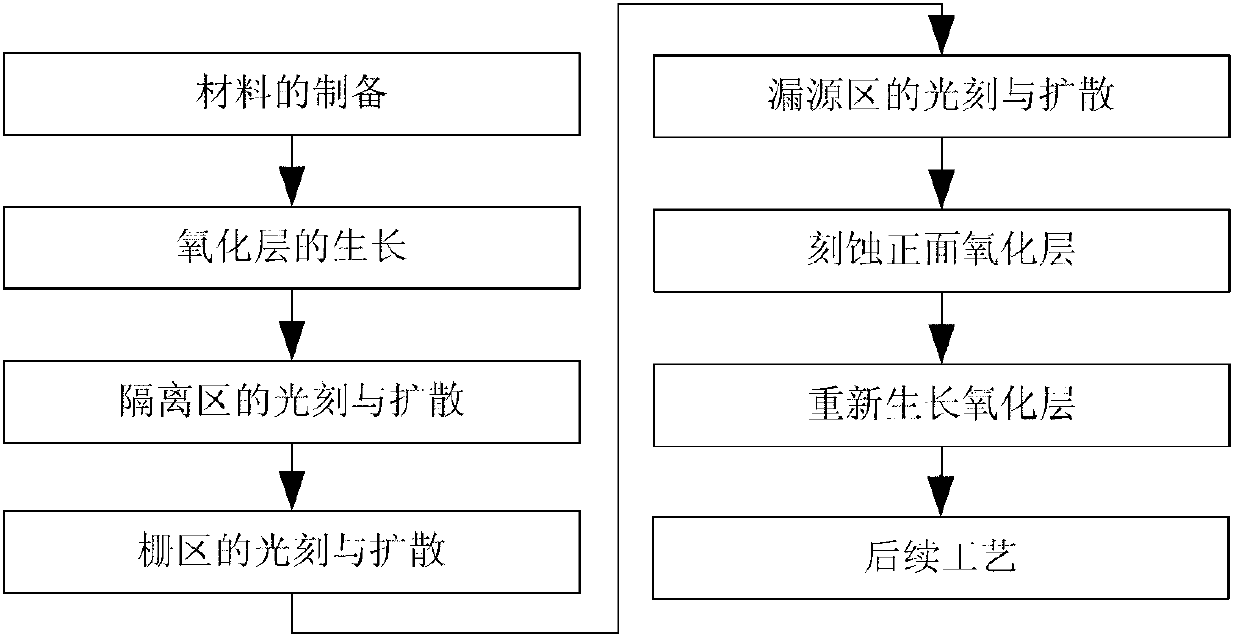

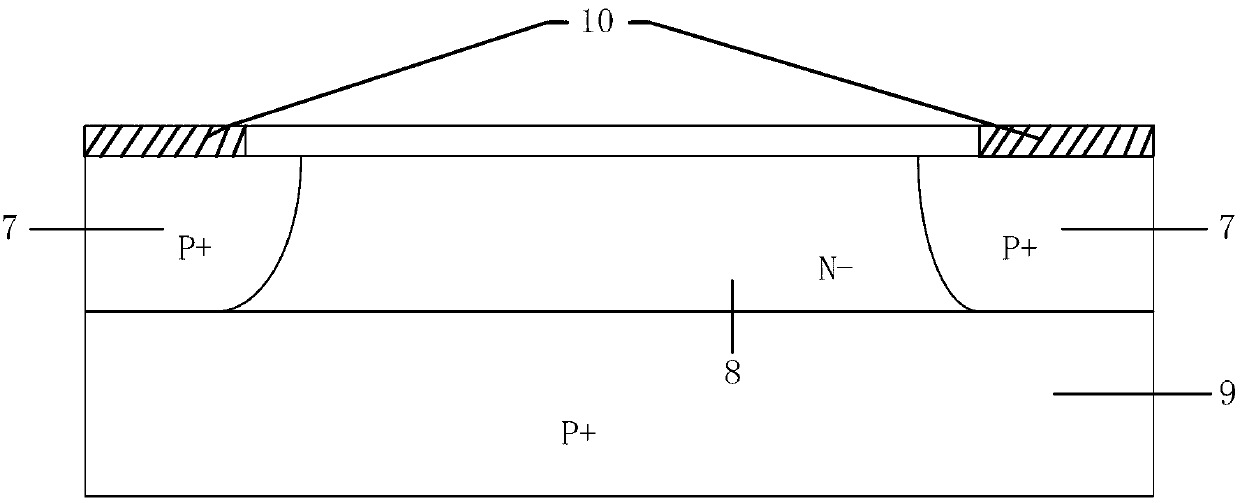

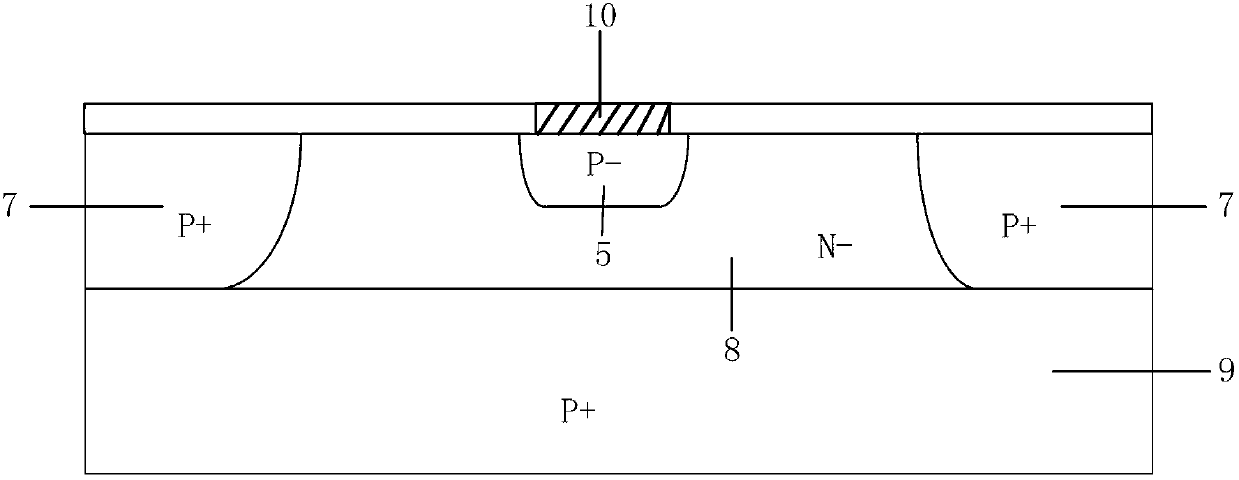

[0028] Now take a kind of N-channel junction field effect transistor with isolation region (its structure diagram is as follows Figure 6 Shown) as an example to describe the proposed method of manufacturing a junction field effect transistor, the specific process is as follows: 400 ~ 450um P + Type substrate and 4 ~ 6um N — Preparation of layer material, growth of oxide layer, photolithography of isolation area, pre-deposition of boron diffusion in isolation area, redistribution and secondary oxidation of boron diffusion in isolation area (corresponding structure diagram as figure 2 shown), photolithography of the gate area, pre-deposition of boron diffusion in the gate area, redistribution and secondary oxidation of boron diffusion in the gate area (the corresponding structure diagram is shown in image 3 shown), photolithography of the drain-source region, pre-deposition of phosphorus diffusion in the drain-source region, redistribution and secondary oxidation of phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com