Cr-doped catalyst for preparing acrylic acid by catalytically oxidizing propane and preparation method of Cr-doped catalyst

A technology for oxidizing propane and catalysts, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of large differences in the yield of acrylic acid, etc., and achieve the effect of convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolving-co-precipitation method prepares the catalyst of the present invention:

[0023] Raw materials: Ammonium molybdate: (NH 4 ) 6 Mo 7 o 24 4H 2 o

[0024] Ammonium metavanadate: NH 4 VO 3

[0025] Telluric acid: H 2 TeO 4 h 2 o

[0026] Niobium oxalate: C 12 h 7 NbO 24

[0027] Chromium nitrate: Cr(NO 3 ) 3

[0028] By catalyst (Mo 7.82 V 1.18 Te 0.94 NbO 28.9 ), use 20 ml of distilled water to stir and dissolve the mixture of ammonium molybdate, ammonium metavanadate and telluric acid at 80°C, then add 20 ml of dissolved niobium oxalate solution, and then add a certain proportion of chromium nitrate solution to Evaporate to dryness at 80°C and dry for 12 h. The catalyst can be obtained by calcining at 150°C and 600°C for 2 hours respectively under the protection of nitrogen.

Embodiment 2

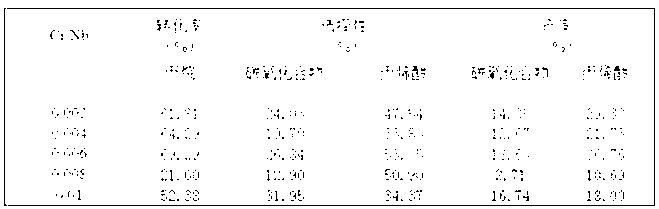

[0030] Catalytic reaction performance of catalysts with different Cr content:

[0031] With reference to the method of Example 1, add 3.5310 grams of ammonium molybdate, 0.3530 grams of ammonium metavanadate, 0.5520 grams of telluric acid and 20 ml of water in No. 1 beaker to dissolve it at 80 ° C, and add 1.6063 grams of niobium oxalate in No. 2 beaker and 20 ml of distilled water to dissolve it at 80°C, and add the solution in No. 2 beaker to No. 1 beaker dropwise to form a 4-component mixture. Add 2.557×10 respectively -3 The mol / l chromium nitrate solution is 2 ml, 4 ml, 6 ml, 8 ml and 10 ml, continue to add distilled water to 80 ml, evaporate to dryness at 80°C and dry for 12 h. Then, under the protection of nitrogen, it is baked at 150°C and 600°C for 2 hours respectively, and the composite metal oxide containing multiple components can be prepared.

[0032] Catalytic reaction conditions: propane / oxygen = 1 / 2, reaction temperature is 390°C, under normal ...

Embodiment 3

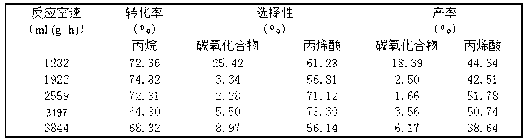

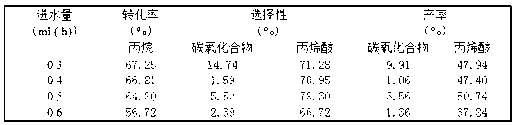

[0036] Catalytic reaction performance at different reaction temperatures:

[0037] Catalyst preparation: with reference to the method of embodiment 1 and embodiment 2, make the Cr that contains element Cr 0.002 Mo 7.82 V 1.18 Te 0.94 Nb 1 o y Multi-component composite metal oxides.

[0038] Reaction conditions: propane / oxygen = 1 / 2, reaction temperature is 390~420°C, under normal pressure, space velocity is 3197 ml / (g.h), water flow rate is 0.5 ml / h. Water is vaporized through a heating tube at 170°C and mixed with propane and oxygen, and the reaction is carried out in a continuous-feed fixed-bed quartz tube reactor. Catalyst evaluation results are as follows:

[0039] Table 2

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com