Micro-fluidic serum extracting chip

A microfluidic and serum technology, applied in the direction of laboratory equipment, test sample preparation, chemical instruments and methods, etc., can solve the problems of blood sample loss, complex mechanical structure, interference of spectral analysis, etc., and achieve simple operation, separation high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 A polymethyl methacrylate serum extraction chip

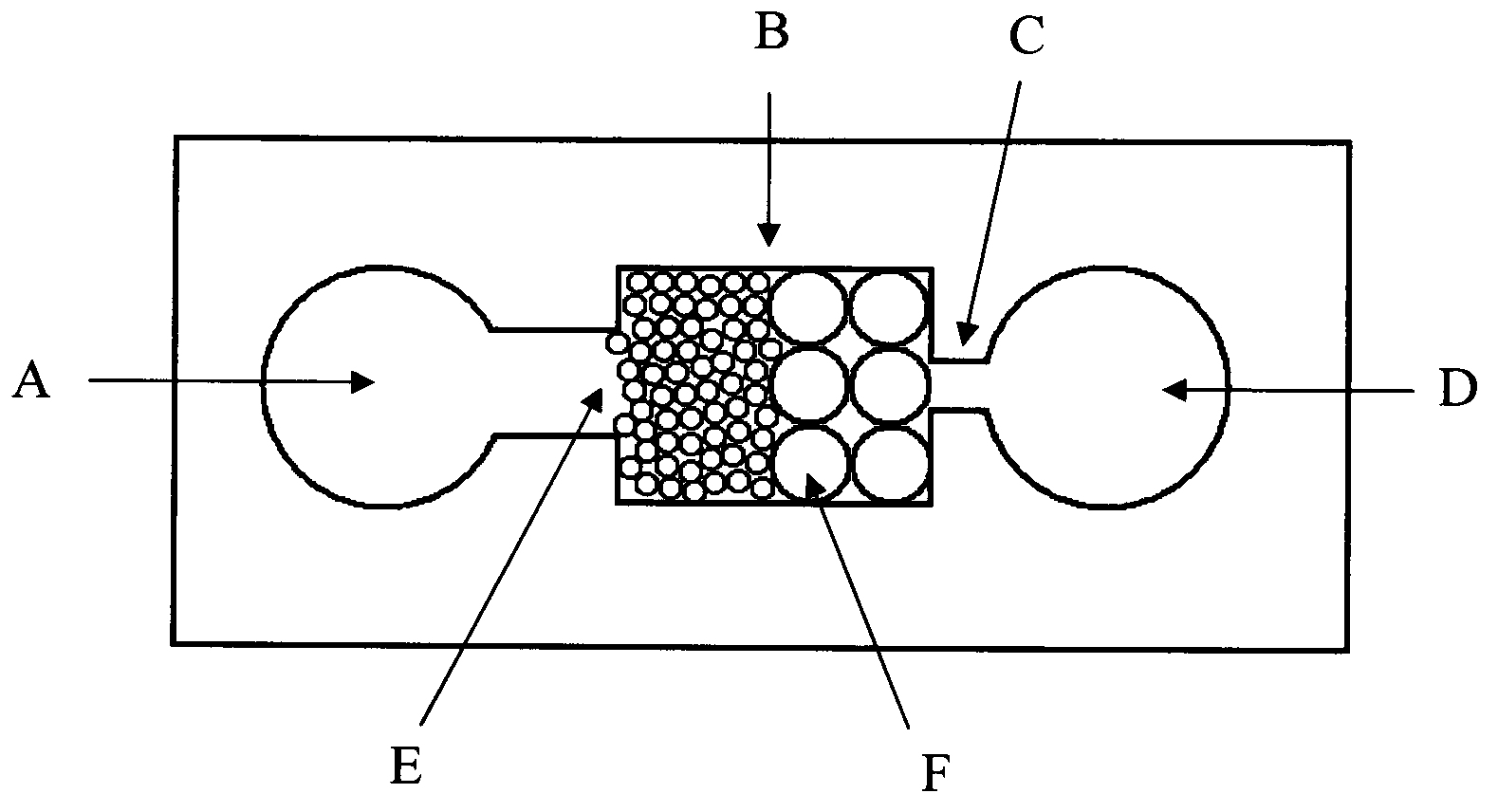

[0016] Such as figure 1 As shown, a kind of serum extraction chip provided by the present invention is made up of sampling pool A, microchannel B, serum separation chamber C, and sample collection pool D, wherein the serum separation chamber is filled with two kinds of glass beads (particle diameter 20 μm and 100 μm, respectively). The chip material is polymethyl methacrylate, and the microstructures are precisely processed by CNC machine tools. The width and depth of the microchannels are 80 μm, and the chips are finally sealed by hot pressing.

[0017] The serum separation steps are as follows: add whole blood from the sample pool, the blood sample flows through the serum separation chamber under capillary force or a certain negative pressure, blood cells are trapped at the front end, and serum flows out from the pores between the microbeads, and finally enters the chamber. Sample collection pool. Using...

Embodiment 2

[0018] Embodiment 2 A kind of polydimethylsiloxane serum extraction chip

[0019] Such as figure 1 As shown, a kind of serum extraction chip provided by the present invention is made up of sampling pool A, microchannel B, serum separation chamber C, and sample collection pool D, wherein the serum separation chamber is filled with two kinds of glass beads (particle diameter 15 μm and 120 μm, respectively). The chip material is polydimethylsiloxane, and the microstructure is processed by casting polymerization method based on photolithography mold. The width and concentration of the microchannel are 100 μm, and finally irreversible sealing is adopted.

[0020] The serum separation steps are as follows: add whole blood from the sample pool, the blood sample flows through the serum separation chamber under capillary force or a certain negative pressure, blood cells are trapped at the front end, and serum flows out from the pores between the microbeads, and finally enters the cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com