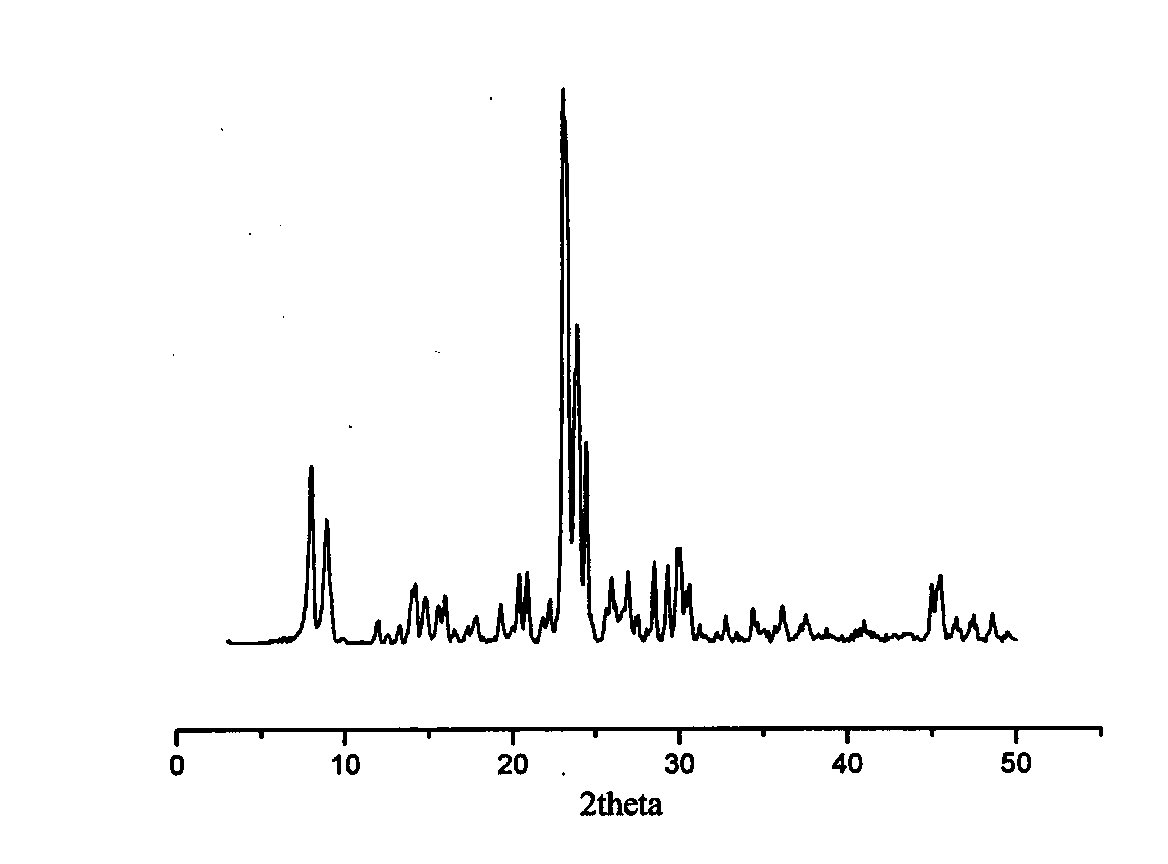

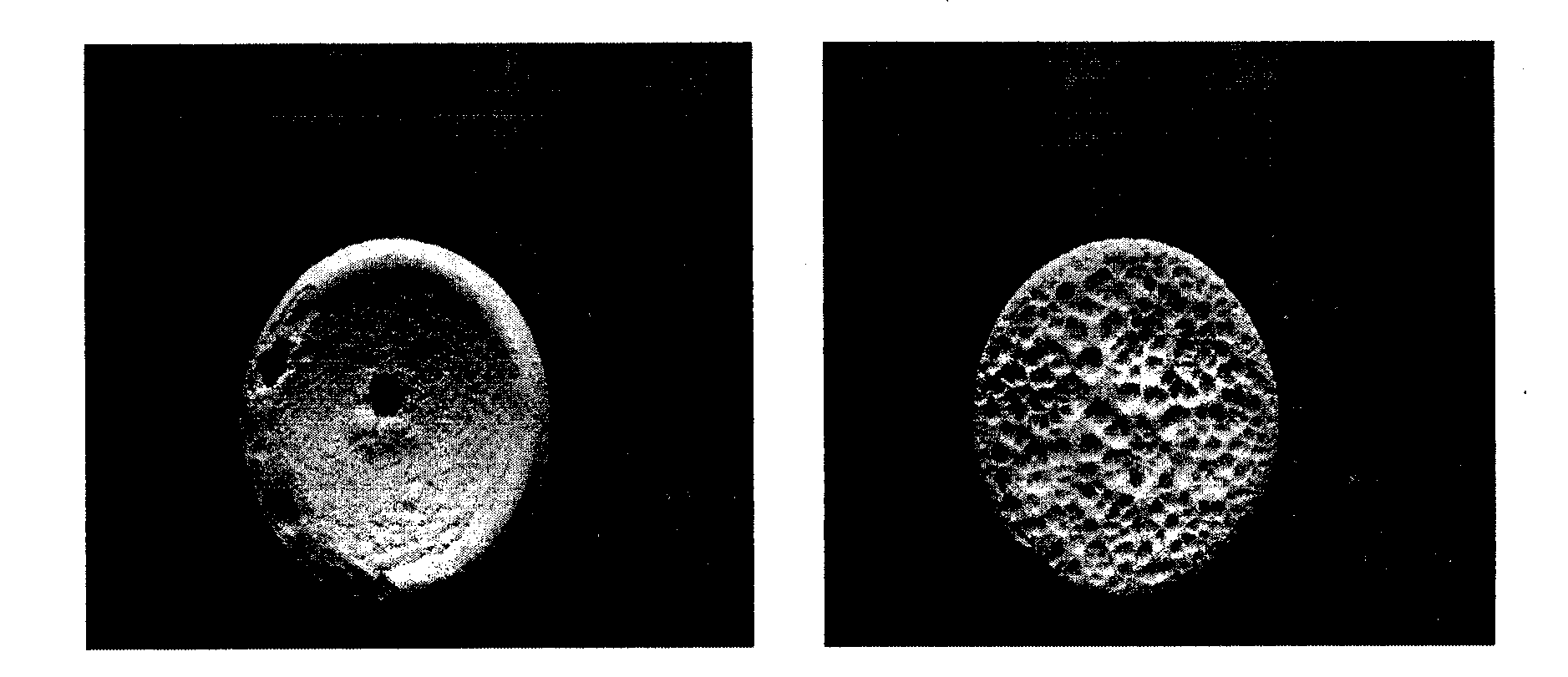

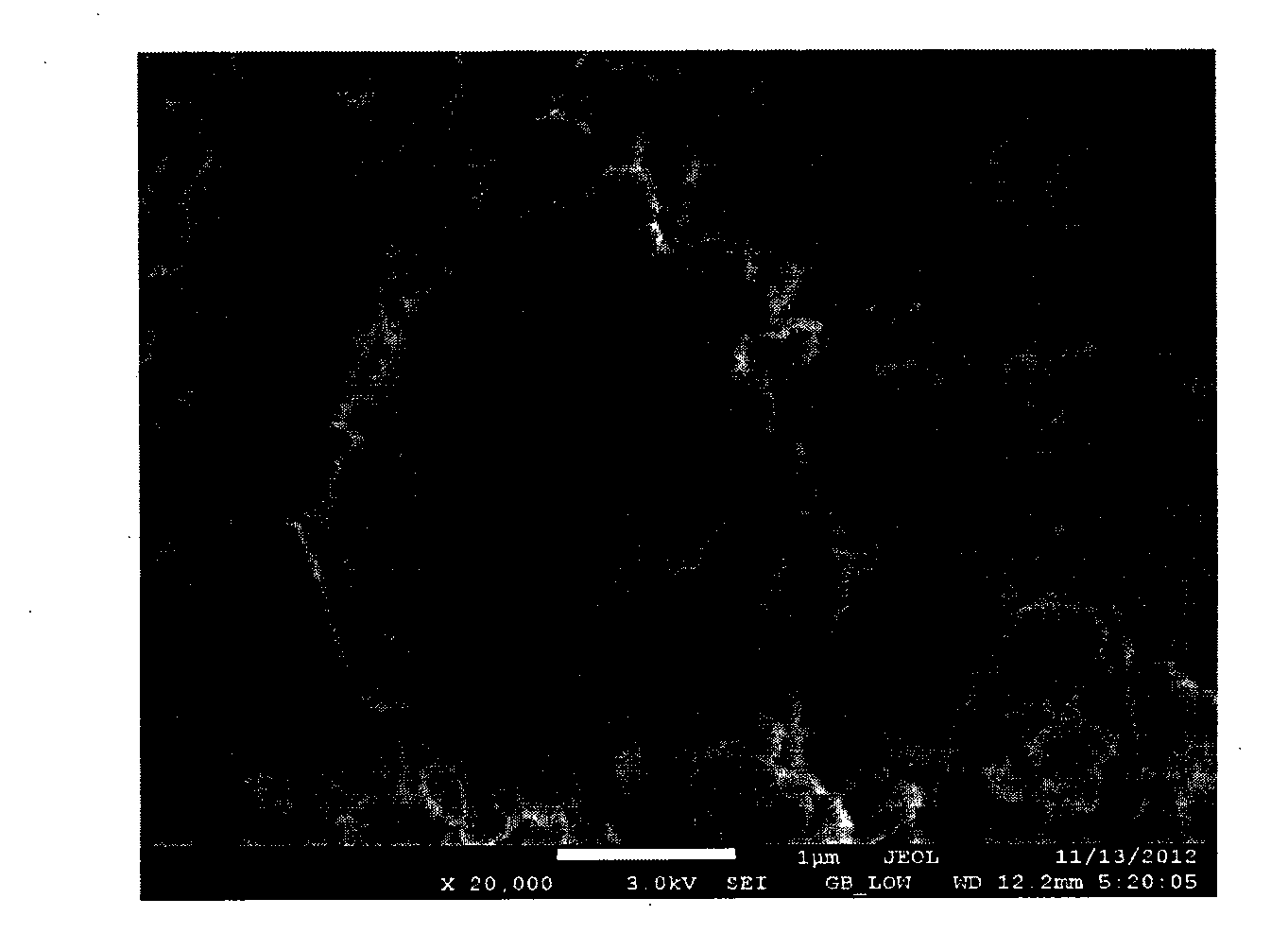

Hierarchical pore ZSM-5 molecular sieve and synthetic method thereof

A technology of ZSM-5 and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., which can solve the problems of blocking molecular sieve channels, high synthesis cost, and reduced content of catalyst active components, etc. problem, to achieve high yield, reduce production cost, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Using ethyl orthosilicate, tetrapropylammonium hydroxide (20%), and deionized water as starting materials, the molar ratio of preparation is 9TPAOH: 25SiO 2 : 480H 2O: 100EtOH synthesis solution, hydrothermally crystallized at 80°C for 6 hours, took out the crystallized product after cooling, and used it as a seed crystal gel for later use;

[0040] (2) Dissolve potassium hydroxide in deionized H 2 Prepare solution A in O, add weighed tetrapropylammonium hydroxide and aluminum isopropoxide into 30% solution A and stir for 2 hours to form solution B, add weighed ethyl orthosilicate slowly Rapidly stir in 30% solution A for 2 hours to form solution C;

[0041] (3) Add B to C and stir rapidly for 5 hours to form solution D;

[0042] (4) Add 0.483g cetyltrimethylammonium bromide (CTA) into 40% solution A, heat at 50°C for 1 hour, then add it into solution D and continue stirring for 1 hour to form a reaction mixture;

[0043] (5) The prepared seed crystal gel was ad...

Embodiment 2

[0046] In step (2) of the present embodiment, potassium hydroxide is dissolved in deionized H 2 Prepare solution A in O, add weighed tetrapropylammonium bromide and aluminum isopropoxide into 20% A solution and stir for 2 hours to form solution B, slowly add weighed tetrapropylammonium bromide 20% solution A was rapidly stirred for 2 hours to form solution C, and other steps were the same as in Example 1.

Embodiment 3

[0048] In step (2) of the present embodiment, potassium hydroxide is dissolved in deionized H 2 Solution A was formulated in O, and the weighed benzyltriethylammonium bromide and aluminum isopropoxide were added to 25% A solution and stirred for 2 hours to form solution B, and the weighed ethyl orthosilicate Slowly add 25% solution A and stir rapidly for 2 hours to form solution C. Other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com