Combined treatment method for rear earth smelting/separating wastewater

A joint treatment, rare earth technology, applied in neutralization water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Effect of Economic Benefit and Resource Recovery Benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

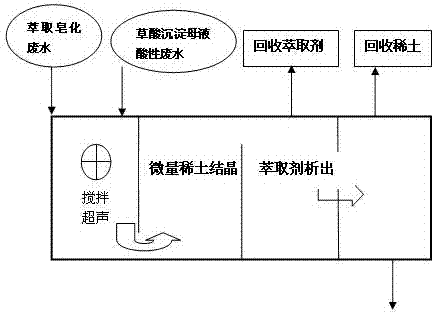

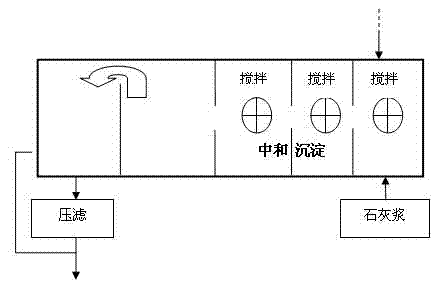

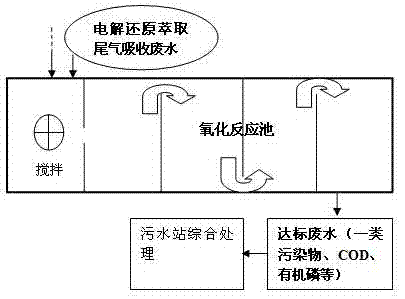

[0022] The used saponification waste water is produced by extracting and separating rare earth with sodium hydroxide as a saponification agent, and the oxalic acid precipitation waste water is used as precipitation to prepare lanthanum oxalate mother liquor. At room temperature, the acidic oxalic acid precipitation wastewater is mixed according to the set ratio to adjust the acidity of the saponification wastewater. After clarification and phase separation, the residual oxalic acid and rare earth crystals in the wastewater are precipitated, and the amount of recovered rare earth and the COD concentration in the wastewater are measured. The water phase separated from the oil phase and solid phase is further neutralized with lime slurry to a pH value of 10-11, and is filtered through clarification to remove heavy metals Pb, Cr and most of the remaining organic extractant and solvent. Add electrolytic redox extraction tail gas to absorb wastewater for oxidation, so as to reduce th...

Embodiment 2

[0025] Determination of ultrasound-assisted demulsification time. Mix 500ml of saponification wastewater and quantitative oxalic acid precipitation wastewater with the above-mentioned optimal ratio, and measure the COD concentration of the wastewater by ultrasonication for different times and static clarification for 5 hours. The results are as follows Figure 5 , Ultrasonic assistance has a significant effect on reducing COD in wastewater, which is beneficial to the recovery of organic extractants and solvents. The ultrasonic time is controlled at 20-28 minutes. The COD concentration in the wastewater is low. With the extension of the ultrasonic time, the COD concentration tends to increase.

[0026]

Embodiment 3

[0028] Determination of the final pH value of lime slurry neutralization and precipitation of a class of pollutants Pb and adsorption of organic substances. Use the above conditions to recover 500ml of wastewater after rare earth and organic extractant, adjust the pH value to 9, 10, 11, 11.5, 12, etc. with lime slurry, stir and react for 30 minutes, and measure the concentrations of Pb and COD in the wastewater after clarification and filtration. Such as Image 6 As shown, it shows that with the increase of pH value, both Pb and COD of the first class of pollutants are significantly reduced. When the pH rises to 10-11, the concentration of Pb is between 0.1-0.2 mg / l, reaching the level of "Rare Earth Industrial Pollution According to the most stringent standard requirements (less than 0.2mg / l), the COD is stable between 500-600mg / l. It shows that the best control point of pH value of lime slurry to neutralize and precipitate a kind of pollutant Pb and adsorb organic substance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com