Spherical polybutylene-1 with high isotacticity and preparation method thereof

A technology of polybutene and isotacticity, which is applied in the field of special catalyst system for dimensional spherical polybutene-1, can solve the problems of complicated production process, production cost, mass transfer, heat transfer difficulty, and reduced production efficiency. Achieving the effect of simple and effective polymerization method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

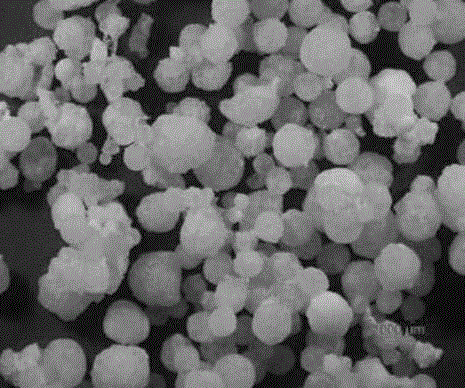

[0036]After the 1L stainless steel high-pressure polymerization kettle (double-screw stirring paddles) was pumped and replaced several times with high-purity nitrogen, 280 g of butene-1 (Bt) monomer, 9 mmol of triethylaluminum, and 0.1 mmol of ethylene were sequentially added to the reaction kettle Triethoxysilane and 0.0383g heterogeneous Ziegler-Natta catalyst (wherein, the carrier is MgCl 2 , the titanium compound is TiCl 4 ; The mass content of titanium in the catalyst is 2.5%, the internal electron donor is phthalic anhydride (the mass content in the catalyst is 0.3%)), the partial pressure of hydrogen is 0.03MPa, 0°C for 0.5h, and then 35°C Constant temperature polymerization for 3.5h, after the end of the polymerization, flash off the unreacted monomers to directly obtain 120g of spherical polybutene (see figure 1 ), the catalytic efficiency is 125.3Kg polymer / gTi, the bulk density is 0.31 g / cm3, and the melt index is 0.5 g / 10min. The content of insoluble matter obtai...

Embodiment 2

[0038] After the 1L stainless steel high-pressure polymerization kettle (double-screw belt stirring paddle) was exhausted and replaced several times with high-purity nitrogen, 280 g of butene-1 (Bt) monomer, 8 mmol of triethylaluminum, and 0.5 mmol of ethylene were sequentially added to the reaction kettle Trimethoxysilane and 0.0292g heterogeneous Ziegler-Natta catalyst (wherein, the carrier is MgCl 2 , the titanium compound is selected from TiCl4; the mass content of titanium relative to the catalyst is 2.5%, the internal electron donor is phthalic anhydride (the mass content in the catalyst is 1%)), the hydrogen partial pressure is 0.03MPa, and polymerized at 5°C 0.5h, then 3.5h of constant temperature polymerization at 40°C. After the polymerization, the unreacted monomers were flashed to obtain 110g of spherical polybutene directly, with a catalytic efficiency of 150Kg polymer / gTi, a bulk density of 0.35 g / cm3, and a melt index 0.8g / 10min. The content of insoluble matter...

Embodiment 3

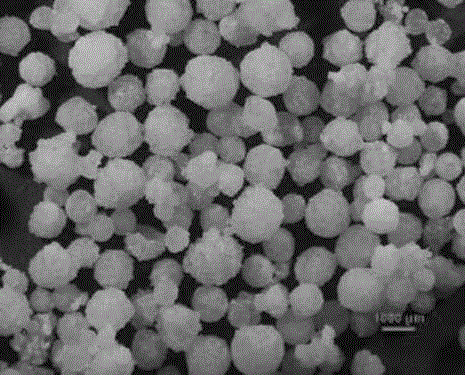

[0040] After the 1L stainless steel high-pressure polymerization kettle (double-screw ribbon stirring paddle) was exhausted and replaced with high-purity nitrogen several times, 280 g of butene-1 (Bt) monomer, 7.8 mmol of triethylaluminum, 0.1 mmol of The heterogeneous Ziegler-Natta catalyst of diisobutyldimethoxysilane and 0.0296g (wherein, carrier is MgCl , titanium compound is selected from TiCl 4 ; The mass content of titanium relative to the catalyst is 2.5%, the internal electron donor is diisobutyl phthalate, (the mass content in the catalyst is 2%)), hydrogen partial pressure 0.03MPa, 10 ℃ polymerization 10min, Then 30°C constant temperature polymerization for 3.5h, after the polymerization, the unreacted monomers were flashed off to directly obtain 100g of spherical polybutene (see figure 2 ), the catalytic efficiency is 135Kg polymer / gTi, the bulk density is 0.29g / cm3, and the melt index is 0.75 g / 10min. The content of insoluble matter obtained by extraction with d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com